Air-loop window walls

5. Structural slab problem

Step 1: The wall anchoring track has three design functions:

- as part of the wall face for aesthetic function;

- as the horizontal wall support for structural function requiring a minimum slab edge distance for the anchoring fasteners; and

- as part of the exterior wall envelope terminating along the seating slab surface requiring air- and water-sealing function between the track and the slab surface. If the wall face is pushed out to protect the slab edge, it will cause the structural problem due to inadequate slab edge distance for the anchoring fasteners.

Step 2: Applying FIC, the three functions must be isolated in order to solve the problem.

Step 3: First, the anchoring track should be used only for its structural function, with the anchoring point as far away from the slab edge as possible. An open-joint slab-edge cover should be used solely for the aesthetic function, while a pressure-equalized hidden membrane covers the slab for preventing the wetting of the slab edge (i.e. water sealing function with no air sealing function). In an air-loop system, the slab edge is completely protected from ultraviolet (UV) exposure and wetting of rainwater by the drainage membrane cover on the slab edge (i.e. the cause of the problem is eliminated). Therefore, the problem is forever solved.

6. Structural anchor problem

Step 1: The track member provides two functions: structural function to transfer the wind load reaction into the floor slab, and the aesthetic role of positioning the wall lines at the theoretical location with small tolerance. Due to the requirement for adjusting the large variations of the floor slab construction tolerances in the up/down direction, various depths of construction shims are required for the aesthetic function, which causes the problem.

Step 2: To eliminate the use of shims (i.e. the cause), the structural function must be separated from the aesthetic function.

Step 3: In an air-loop system, a two-member track design is employed. The anchoring track (without shim) is used for the structural function while a positioning track is engaged into the anchoring track using the engagement depth adjustment (again without shim for the up/down tolerance adjustment) for the aesthetic function. The problem is forever solved since the cause has been eliminated.

7. Field productivity and quality control (QC) problem

This problem is permanently solved due to the two-member track design as explained in Problem 6.

8. Water leakage problem

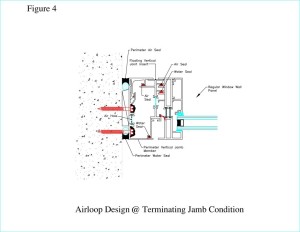

Step 1: The cause of the problem is the required dual functions of the terminating jamb member.

Step 2: Applying the FIC concept, a terminating jamb can be used to seal members—see the image at right—forming the boundary water and air seal with pressure-equalized air in between (i.e. sealing function). The non-structural floating vertical joint insert can maintain the air-loop design between the terminating jamb member and the adjacent window wall panel.

Step 2: Applying the FIC concept, a terminating jamb can be used to seal members—see the image at right—forming the boundary water and air seal with pressure-equalized air in between (i.e. sealing function). The non-structural floating vertical joint insert can maintain the air-loop design between the terminating jamb member and the adjacent window wall panel.

Step 3: In this arrangement, the structural function is maintained by the wall panel and practically no wind load reaction can be transferred into the terminating jamb seal member through the floating vertical joint insert. Therefore, the sealing function is separated from the structural function. The problem is forever solved since the cause has been eliminated.