Daylighting and performance considerations for polycarbonate glazing systems

Images courtesy EXTECH

Diffusion and glare reduction

Diffusion is the ability of a glazing system to spread light from the sun evenly, so as to reduce glare and harsh shadows. Choosing the optimal amount of diffusion can be critical to the building occupants’ comfort and concentration. Too much light can result in “hot spots” with reflections on computer screens. Too little light can lead to poor comprehension and inaccuracies. Both extremes can cause eyestrain and headaches. (For more information, see “Lighting, Well-being and Performance at Work” at or “The Dark Side of Poor Lighting.”)

Currently, there are no simple performance measurements allowing for an easy comparison between diffusion and glare of glazing materials and daylighting systems. Working with a daylighting analyst, complex modeling can generate discomfort glare data by:

- reviewing each daylight opening in every elevation of a building;

- calculating the incoming seasonal and daily solar radiation transmitted through the glazing material of each opening; and

- inputing illuminance, the amount of light that falls on a surface, and luminance, the amount of light received by the eye, for each daylight opening and for each viewpoint within each room.

In general, high diffusion usually is achieved by lowering the amount of light transmitted through the glazing material. Polycarbonate systems most often are specified with an opal color glazing, which delivers moderate to high diffusion for evenly distributed light.

Polycarbonate systems specified with clear glazing have a low diffusion, and correspondingly, a high light transmission. While appropriate for some applications, clear glazing can produce unwanted hot spots in areas with a large amount of direct light.

Light transmittance

Light transmittance (LT) is an optical property describing the percentage of incident visible light transmitted through the glazing material.

LT varies greatly based on the technology and composition of the specific glazing material.

Daylighting assemblies that utilize older technologies like FRP often have an LT range as low as 12 to 20 percent. With light transmissions this low, substantially more FRP material is required to maintain the same light levels as systems with a higher LT. The addition of fiberglass infill insulation to these systems can further reduce LT.

Daylighting assemblies relying on polycarbonate glazing or multipane IGUs have an LT range of approximately 45 to 70 percent. Compared to FRP, these materials provide a higher LT per square foot, improving the amount of daylight entering the structure, while reducing overall system costs.

UV resistance and yellowing

Since polycarbonate glazing systems are constantly exposed to the sun, they are co-extruded with a layer to resist UV radiation and eliminate yellowing. UV degradation is measured using a yellowness index, DYI. Following ASTM Method E313-15e1, Standard Practice for Calculating Yellowness and Whiteness Indices from Instrumentally Measured Color Coordinates, DYI is calculated from spectrophotometric data describing the change in color of a test sample from clear or white toward yellow.

The color of the polycarbonate glazing material should not change more than five units, per ASTM D2244-16, Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates, after 60 months exposure to outdoor weathering in Arizona, as determined by an average of at least two samples. In addition to a change in color, DYI correlates with a proportionate amount of LT loss. A DYI greater than five also reduces the material’s impact resistance. Manufacturers’ warranties for polycarbonate products will reflect the effectiveness of its UV protection.

Durable performance

Beyond supporting buildings’ daylighting design goals, polycarbonate glazing systems are recognized for contributing to the projects’ durability, safety, and sustainability.

Impact resistance

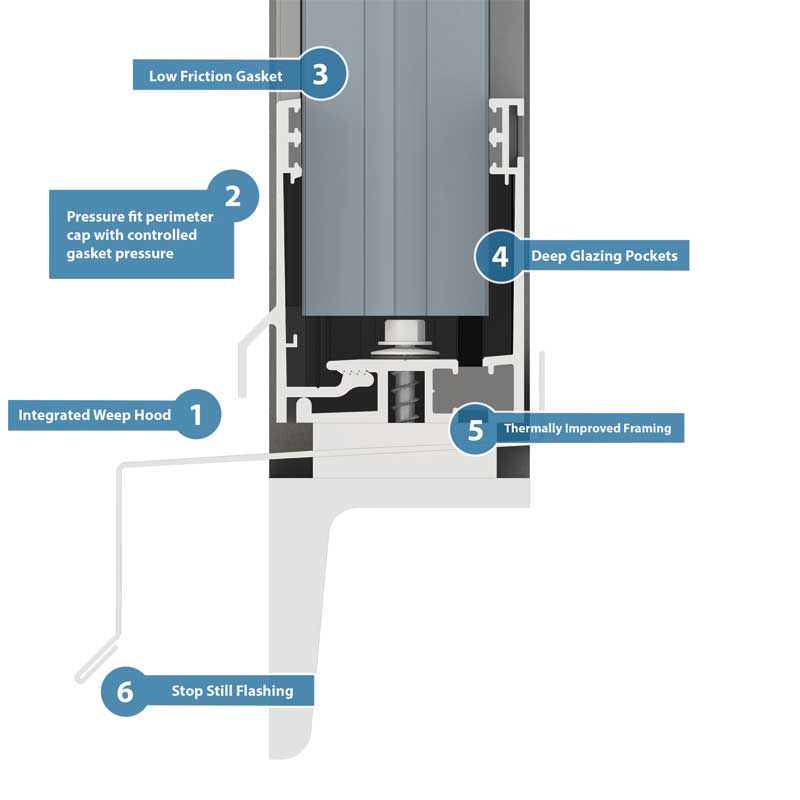

Polycarbonate is 250 times more impact resistant than an equivalent thickness of annealed glass, and 30 times more than non-modified acrylic. Polycarbonate also crushes more easily than glass and acrylic. On most glass and acrylic systems, and some polycarbonate glazing systems, pressure caps are fastened with screws. Installers must be trained to not over-tighten the screws, risking damage to the system and its intended performance. To address this, some polycarbonate glazing system manufacturers incorporate special framing designs to restrict the pressure of the gasketing against the polycarbonate. This is called controlled gasket pressure.

Employed in exterior vertical walls, the high impact resistance of polycarbonate glazing systems helps protect against vandalism and storm damage. For glazing systems installed in buildings exposed to extreme wind conditions, testing according to ASTM E1996-17, Standard Specification for Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Windborne Debris in Hurricanes, consists of shooting a small or large missile at a product sample.

The most stringent building codes in hurricane-prone coastal zones (e.g. Miami-Dade, Florida, and Texas) require ASTM E1996’s large-missile impact testing protocols. To meet these high-performance requirements, manufacturers may need to modify or customize their products. For example, polycarbonate vertical wall systems may require close spacing of framing or other reinforcement, which may raise aesthetic issues.