by Marc Snyder, LEED AP

Located in Fort Collins, Colorado State University’s (CSU’s) Pavilion transcends physical bounds to teach students sustainability through materials, advanced systems, and programmatic features. Showcasing unique passive technologies, its katabatic cooling tower and its Trombe parapet wall are a dynamic duo making this green structure truly innovative.

That a post-secondary institution specifically sought a green, high-performance building is unsurprising. U.S. college and university applicants are recommended to seek out between five and 10 schools. This year, 20.2 million students are attending—an approximate 4.9 million increase since 2000. (These statistics come from College Board (the organization who runs SAT, ACT, and AP tests) and the Institute of Education Sciences of the National Center for Education Statistics. Visit www.nces.ed.gov) In the last decade or two, these changing dynamics are driving institutions to match increasingly higher expectations and battle one another to recruit the best of the best.

One of the ways to make campuses appealing is creating facilities that support and enhance every facet of the college experience. One of these methods involves showing a strong commitment to the environment. Indeed, the 2015 Princeton Review “Hopes and Worries” survey reported:

a majority (60%) of respondents said having information about colleges’ commitment to environmental issues would contribute ‘strongly,’ ‘very much,’ or ‘somewhat’ to their application/attendance decisions.(See “The Benefits of Sustainability,” by Tod Stevens and Chris Mackey, published on UniversityBusiness.com)

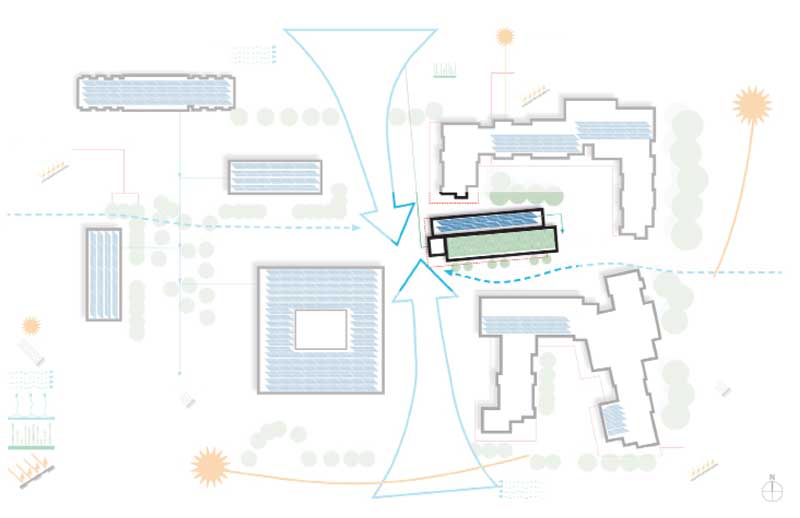

For CSU’s new building, the design team included 4240 Architecture, along with sustainability consultant Ambient Energy and Cator Ruma & Associates (mechanical engineer). Its concept began simply as a pavilion positioned between two new residence halls. However, what could have easily become a simple mailroom and social space quickly evolved to a bigger idea for the heart of a residential village.

Collaborative charrettes involving stakeholders, designers, and passive design experts steered those early conversations toward sustainability. A logical focus for the programming included offices for an on-campus environmental group, the Ecoleaders, and a student-led teaching and learning bike shop. Careful analysis of student movement through the site, the sun and wind patterns in the area, and input from future users all played a fundamental part in establishing the design direction. As a result, the project achieved Platinum under the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED) rating program—a first for the university.

Images courtesy 4240 Architecture

Visioning a tower that breathes

Thorough site analysis revealed a unique opportunity to leverage the dry climate and large daily temperature swings of Fort Collins. With lofty high-performance building goals, the team undertook extensive research on wind and cooling towers with passive evaporative cooling techniques used in the Middle East and Western United States. Traditional Persian architecture has employed ‘windcatchers’—a version of a cooling tower—for thousands of years. Referencing a more regional example, the team looked at Zion National Park Visitor Center’s passive cooling tower system that regulates inside temperatures. The park, located in Southwestern Utah, reported using 70 percent less energy than a building of comparable size and function in 2010. These passive tower precedents use natural ventilation and convective forces to cool buildings, only requiring active systems during extreme conditions, if at all, as backup to the passive systems.

The team applied the extensive research to leverage the low relative humidity (RH) levels of the semi-arid climate characteristic of Northern Colorado. In its essence, the Pavilion’s katabatic tower functions much like the precedent towers. (From the Greek word katabasis, meaning ‘descending,’ katabatic winds carry high-density air from a higher elevation down a slope under the force of gravity.) In the cooling season, it draws in warm, dry air through high-performance coated metal louvers at the peak of the tower with an inverted diamond roof shape enhancing natural air flow. During the warming season, mechanical dampers in the tower main shaft close, thus minimizing any potential heat loss from the building.

The tower roof design was refined during design with detailed study of the local wind rose (i.e. a resource giving a succinct view of how wind speed and direction are typically distributed at a particular location) and surface roughness analysis, which measures variations in wind patterns due to obstructions. Each tower variable was adapted to catch prevailing wind and enhance vertical drop of the outside air.

As it enters the tower, the outside air is directed through a fine cool mist produced by recirculating water via a misting system located at the top of the tower. After passing through the mist, the now denser and cooler air falls to the bottom of the tower and is then drawn out by natural convective forces, through vertical wall registers, or to far reaches of the building through a concrete trench duct below the first floor slab.

Utilizing the naturally cool temperature of the earth, the concrete trench duct is integrated into the building foundation and helps further cool the tower air as it is carried throughout the building. The design and operation of the trench duct relates closely to the Persian Qanat, or underground canal, that is sometimes used with windcatchers to passively cool the air. Essentially, both of these systems passively move air through the ground in a form of geothermal exchange.

At the end of the trench duct, diffusers were specified to help achieve a lower air velocity with displacement ventilation and promote a ‘pool’ of slow-moving air for more effective air distribution and user comfort. Initial design produced an uncomfortable face velocity coming out of the diffusers in some locations at 2.5 m (8 ft) per second, which is about 9 km/h (5.5 mph). Occupant comfort is essential in this space; therefore, it was found through modeling iterations that diffuser size, openness, and dimension could be adjusted to produce a user-friendly face velocity of 1 m (3 ft) per second (or lower)—about 3.2 km/h (2 mph)—and effectively blend the passive air systems into the background, making it unnoticeable in the user’s experience.