Time to torture the tiles

Once the installation methods and materials had been worked out and optimized, the next step was to test the total installation. Without an existing set of international and/or national standards for thin tiles, a more creative solution was needed to stringently test the performance of the tiles themselves under known conditions.

A Universal Flooring Tester was employed to perform ASTM C627, Standard Test Method for Evaluating Ceramic Floor Tile Installation Systems Using the Robinson-type Floor Tester. This simulates, in a reproducible way, the strains on a floor equal to a residential home environment all the way up to the most strenuous commercial applications. The stresses range from high heels to rolling loads, forklifts, and commercial equipment.

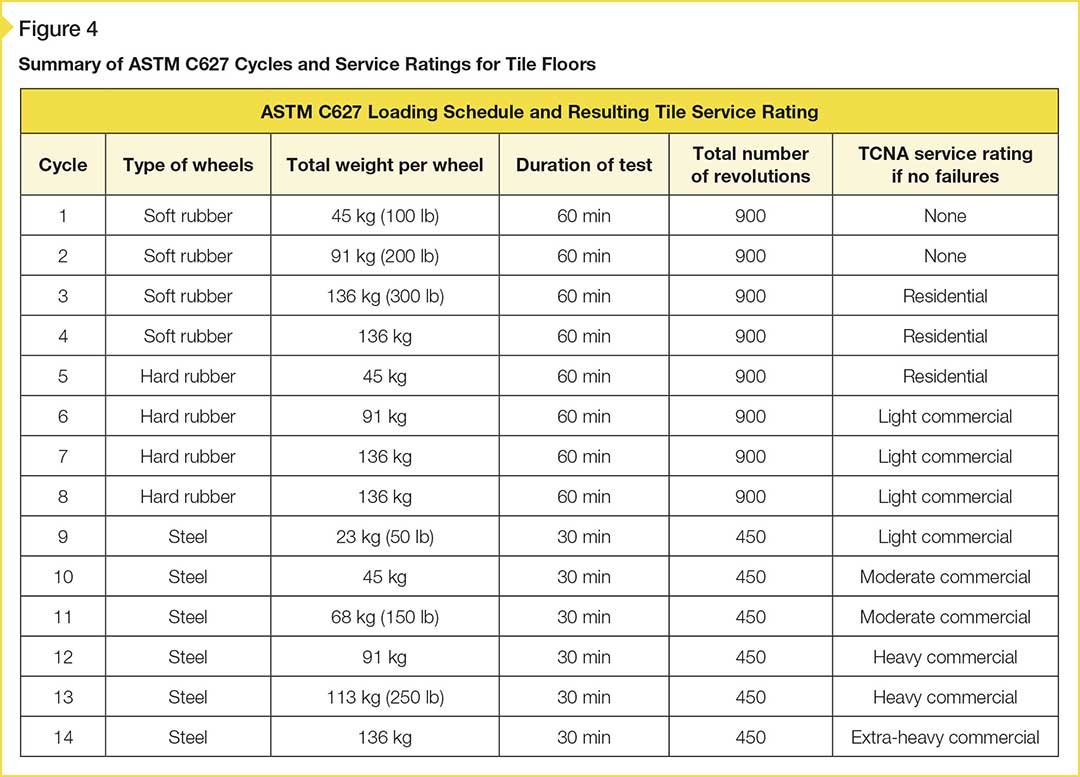

ASTM C627 was developed using a series of wheels of different hardness to assess the installed flooring system’s ability to withstand the real-world stresses found in residential and commercial installations. TCNA has assigned tile service ratings based upon the number of cycles successfully completed. To be given a particular rating, the flooring system being tested must not fail during the given cycle. The first time failure is noted, the test ends and the previous cycle’s rating is applied (Figure 4).

Using this test method (among several others), various thin tiles from many manufacturers were tested for adhesion, water resistance, and resistance to compressive loads. During the testing, the use of the leveling systems was confirmed as a best practice. It was also found there was a reproducible pattern to the failures observed with thin tiles. The testing of the thicker 4.5 to 6-mm (0.18 to 0.24-in.) tiles showed the most reproducible. With the proper tile, results up to ‘heavy commercial’ were reproducibly obtained. The result was shown to be tile-specific, so the thin-tile manufacturer must be party to any decision about its product’s performance rating. The techniques developed for floors also work for walls and exterior installations by analogy, since the coverage requirements are the same.

Looking toward the future

Tile manufacturers continue to work to improve their processes and make thin tiles stronger and better, and mortar and installation techniques are continually being developed and refined. There is a real opportunity for the industry to capitalize on all the advantages initially discussed at Cersaie in 2009. The cutting edge—the thin tile edge—is catching on, creating new opportunities for both designers and product manufacturers to bring lasting, sustainable beauty to the marketplace.

Neil McMurdie, PhD, oversees the development of new technologies and products for MAPEI Americas. He has 17 years of experience in chemical research, and is a member of the American Chemical Society (ACS), the Materials and Methods Standards Association (MMSA), the American Concrete Institute (ACI), the Adhesives & Sealants Council (ASC), and the Ceramic Tile Distributors Association (CTDA). McMurdie received the U.S. Environmental Protection Agency (EPA) Presidential Green Chemistry Challenge Award in 2001, and he is a holder of nine U.S. patents. He can be reached at nmcmurdie@mapei.com.