by Chuck Mears, FAIA

The marriage of shape and sound are used to create world-class acoustical experiences inside the New World Center, designed by Frank Gehry, and the Kauffman Center for the Performing Arts, designed by Moshe Safdie.

Billowing clouds, curved ceilings, and swooping lines all have dramatic impact on the way concertgoers experience sound. Both architects relied on the use of curved surfaces to diffuse sound and to create the distinctive appearances, each with dramatically different visual results.

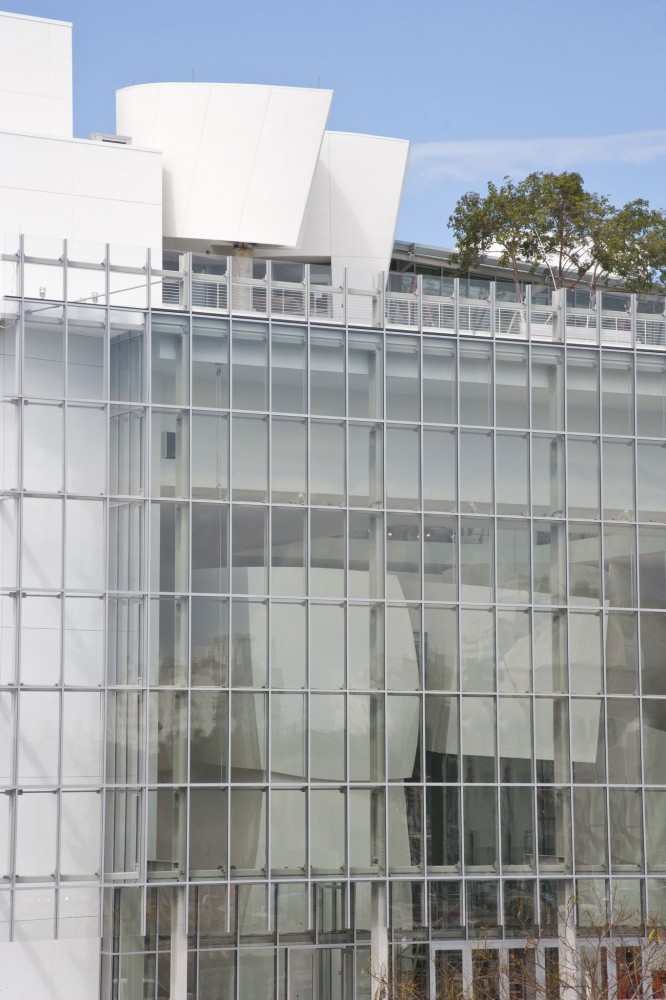

Gehry chose to expose the curved elements, enclosing them in a glazed box that allows passersby to glimpse the flowing interiors. Safdie used giant curves to define the shape of his building, composed of two symmetrical half shells of vertical concentric arches, which perch on a magnificent site overlooking the city. However, in both cases, the ability to interpret the acoustician’s nuanced instructions to exacting perfection was the key to creating an acoustical masterpiece in two of the United States’ most important symphonic institutions.

This article deconstructs the delicate balance between shaped walls, curved ceilings, and sound—principles that can apply in any performance space.

A look back in time

Concert halls have historically been designed with the architectural trends of the day. The science of architectural acoustics is just over a century old, but before it was hit or miss. Many of the early European halls, which were heavily ornamented on the walls and surfaces, were fortunate accidents, as the ornamentation served to diffuse sound.

It was not until Wallace Clement Sabine, an assistant professor at Harvard, was called on to correct an acoustically disastrous lecture hall on campus that modern acoustical science was launched. Sabine was able to determine, through experimentation, there is a definitive relationship between the quality of the acoustics, the size of the chamber, and the amount of absorption surface present. In 1898, he formally defined ‘reverberation time’—still the most important characteristic currently in use for gauging a room’s acoustical quality—as the number of seconds required for sound intensity to drop from the starting level by an amount of 60 dB.

In the 20th century, with growing popularity of ticketed concerts, many cities decided to build large-capacity venues, basing them on the parallelepipic form employed in some churches. The first reference model, called the ‘shoebox,’ places the orchestra directly in front of the audience; with musicians and spectators face-to-face. When designing for this type of architecture, acousticians must consider the shape and volume of the auditorium, and the materials used to achieve the ideal acoustic experience. What volume is required? How should the room be shaped?

Most auditoriums built since the 1950s have reproduced or adapted the shoebox model, which has the advantage of being well referenced, and therefore mastered by acousticians. However, contemporary architects like Safdie and Gehry are redefining the old models, and acousticians are learning new ways to incorporate complex design trends with the current knowledge base of acoustical engineering.

the Kauffman Center for the

Performing Arts’ prosceniumstyle

Muriel Kauffmann Theater

brings world-class cultural

events to Kansas City, Missouri.

Shown here are both early

framing and completed work.

The sound (and reverberation) of music

The sound (and reverberation) of music

On a clear summer night, an outdoor concert can be entrancing. However, entering a well-designed concert hall can be even more magical, as the audience is enveloped in the music. This is because sound in a concert hall is related to vibrational energy.

Sound results from pressure fluctuations that travel through the medium of air. Various sources, such as an opera singer, a viola, or a horn, generate the air vibrations. The vibrations occur at varying rates, resulting in different frequencies of sound, which are perceived by humans as different pitches.

Low-pitched sounds (like that produced from a bass drum) vibrate at low frequencies, such as 20 to 250 cycles per second, or hertz (Hz). High-pitched sounds (like that of a piccolo) vibrate at high frequencies, such as 5000 to 20,000 Hz. Generally, humans can hear sounds from 20 to 20,000 Hz. These vibrations emanate in sound waves, which travel around the room, becoming reflected, absorbed, or transmitted at the walls or boundaries of the room. This is why the shape and size of the space, background noise, reverberation, as well as its material properties, are important.

In an enclosed environment, sound reflects—or reverberates—for a period after a source has stopped emitting sound. A space with a long reverberation time is known as a ‘live’ environment. Conversely, when sound dies out quickly, it is called a ‘dead’ environment. Speech is best understood in the latter, but music can be enhanced in the former, as the notes blend together.

Adding to an acoustician’s checklist are the different types of music that will be played in a space, as many venues today accommodate various styles. Reverberation time is affected by size and amount of reflective or absorptive surfaces in a space, making it one of the key considerations in a concert hall’s overall design and architecture.

meets function—curves are both

expressive aesthetic and carefully

considered acoustic component.

Kauffman Center for the Performing Arts

Kansas City, Missouri’s Kauffman Center landed the Midwestern city among the ranks of world-class theaters like the Berlin State Opera in Germany and Disney Concert Hall in Los Angeles. The approximately 26,500-m2 (285,000-sf) facility has two technically sophisticated performance spaces: the proscenium-style Muriel Kauffman Theatre and Helzberg Hall.

With a seating plan similar to the traditional horseshoe of opera theaters in Europe, the Muriel Kauffman Theatre houses an acoustic infrastructure disguised within the aesthetics of the space, and showcases the integration of the architectural imagination with acoustical engineering.

Architect Moshe Safdie wanted the audience to experience a sense of warmth and intimacy with the performers. Referencing the fanning element of the facility’s north façade, the Muriel Kauffman Theatre curves around the seating pit and balcony; it naturally focuses sound waves to each of the 1800 seats.

arts spaces in the Kauffmann Centre.

Acoustic bumps were used behind

an acoustically transparent mesh.

The seats were built with materials that narrow down the range between sound reflectance and absorption when occupied and when vacant—a difference of only 0.2 seconds. At the same time, semi-cylindrical bumps were installed behind the louver wall to balance out the acoustical focusing caused by the round shape of the theatre. Further, shallow balcony overhang design helped deliver direct sound to the audience from the stage. In this balancing act of absorption and reflection, shapes and textures have everything to do with the sound quality.

Similar to their design for the Muriel Kauffman Theater, Nagata Acoustics (Los Angeles) designed cylindrical, convex, acoustic elements behind acoustically transparent materials for 1600-seat Helzberg Hall. Similar to drawing a curtain on a messy room, these barriers conceal the bulky framework of an acoustical system, but do not stifle their acoustic properties. As captured so elegantly through Safdie’s design, acoustical materials are no longer an aesthetic obstacle for the architect.

Continuing in Helzberg Hall, architects and acoustical engineers worked against the challenge of maintaining sound intimacy in the face of a large expanse between the audience and performers. By devising a round room in which all the surfaces work together to reflect sound three-dimensionally, the team could channel the direct and clear sound reflections to each audience member.

Surface materials were a key part of the acoustic design in both performance spaces at the Kauffman Center. To channel quality acoustics up to the balcony from the Helzberg Hall stage, Safdie designed a shallow overhang to reflect the sound. Made of plaster with a sandblasted finish, the balcony’s surface materials are essential to the theatre’s ability to diffuse sound.

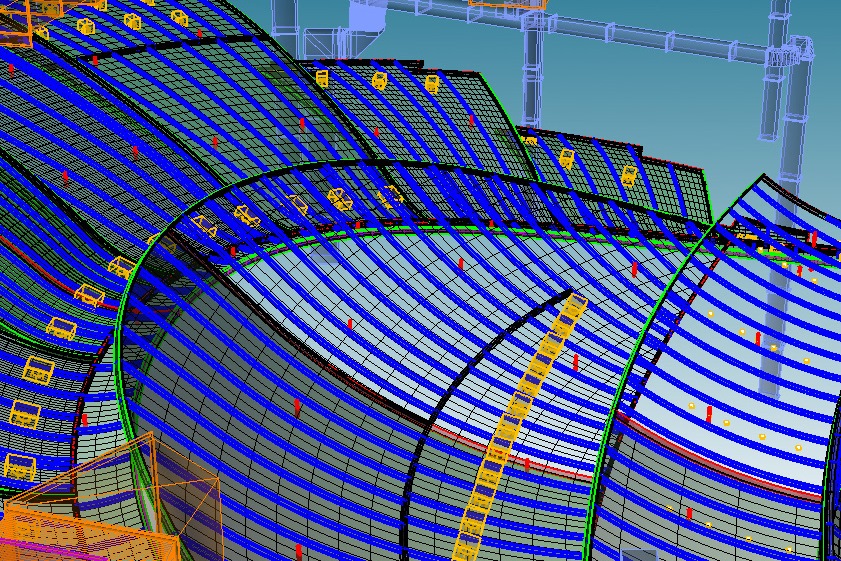

Performance Contracting Inc. (Lenexa, Kansas) worked with the curved cold-formed steel (CFS) framing provider to devise an advanced, structurally engineered framing approach to support the per-square-foot weight of the plastered acoustic surfaces, which included more than 907,000 kg (2 million lb) of acoustical plaster.

This weight of plaster was used to keep sound from transferring. To achieve this, the plaster on the ceilings had to be 63.5 mm (2 ½ in.) thick to meet the STC rating—1.2 to 1.4 kPa (25 to 30 psf). With nine different density requirements across varying plastered surfaces inside the concert hall, the geometry had to be perfect.

The process of tuning a musical venue has evolved from a ‘close enough’ mentality to extremely precise acoustical methods. In this case, the team’s process used 92 mm (3 5/8-in.) pre-curved studs tied to 19-mm (¾-in.) pre-curved cold-rolled channel framing to provide a precise and acoustically specific profile. Additionally, the perimeter of each of the acoustic elements created with the stud-channel framing methodology was finished with a custom-formed 110-mm (4 3/8-in.) track to provide crisp, clean edges and corners.

Kauffman’s complex geometry required an acoustic design complete with ‘bumps’ of various sizes in specific locations in each hall. For these elements too, the CFS framing provider prefabricated a complete kit of required parts, which was shipped to Kansas City and easily assembled onsite, reducing jobsite labor and installation time.

New World Center

Nagata Acoustics was also involved in the New World Center—Gehry Partners’ Miami project that used billowing shapes and acoustic clouds to render perfect pitch for the main performance space and practice rooms. Home to New World Symphony, the facility provides the noted orchestral academy with the space to “prepare highly gifted graduates of distinguished music programs for leadership roles in orchestras and ensembles around the world.” The centerpiece of the building is an adjustable 757-seat natural acoustic performance space, featuring large, distinctive sail-like acoustical surfaces designed for the ultimate orchestral experience.

Although New World Center is comparable to Helzberg Hall in its stage size and program capacity, the size of the room is smaller. Acoustically, this means less distance between the stage and the audience; therefore, the reflective surfaces are closer.

Sound in a compact space can be perceived as louder. By increasing the ceiling height to 15 m (50 ft), the room volume expanded and the level of sound decreased. The room, and consequently its sound, can be adjusted to a dazzling array of options, as Frank Gehry designed 14 different stage configurations within the hall’s trapezoidal shape. Seats can be retracted to add floor space and satellite platforms allow for performances off the main stage.

Five huge acoustic sails were among the primary tools Nagata’s acousticians used to focus sound. The sails are the focal point of the stage and also serve as video panels that enhance the concertgoer’s experience. The team was challenged to maintain the architectural ‘swoops’ of Gehry’s design and make it work acoustically. Some modifications were made to improve acoustics: tilt angles were adjusted, curvatures were changed slightly, and other tweaks were incorporated to deliver early reflections to the audience.

Such precision meant the CFS framing provider—working closely with Lotspeich Company, the specialty contractor responsible for metal stud framing, drywall, gypsum plaster, acoustical plaster, acoustical ceilings, and wall panels—had to be geometrically precise in fabricating the custom curved framing to create the exact shapes Gehry wanted.

Using 3D modeling, curved studs, curved box beams, curved channel, and knife edges were designed to meet the design intent and acoustic requirements. During this stage, there was also analysis with adjacent systems for clash detection and fit informed the design solution. The entire framing system was coordinated with audiovisual (AV), air-conditioning (AC), and lighting systems to fit seamlessly.

The CFS framing’s 3D model provided the data to fabricate 46,975 m2 (505,638 sf) of material, which included 3432 curved studs, and 2632 curved track framing pieces. Ninety four percent of the materials were created uniquely for the project. The company even developed a proprietary new construction method—knife edges—for corners that were not at right angles (a condition common in Gehry’s design). Every detail was designed with the project’s ultimate goal in mind: marvelous acoustics.

![An evening view of the New World Center, featuring The Wall (a 650-m2 [7000-sf] projection wall) and SoundScape (a 1-ha [2.5-acre] multiuse urban space).](http://www.constructionspecifier.com/wp-content/uploads/2014/06/NWSP-7840-1000x656.jpg)

performance hall delivers a

multimedia experience with

crisp acoustic integrity.

Conclusion

Streamlining the construction process from blueprint to acoustic plaster element or complex ceiling design is achieved with advanced building information modeling (BIM), 3D modeling, CFS fabrication, and framing technology. This combination opens up unlimited acoustical opportunities for performance spaces around the world.

No longer are designers limited by straight lines and right angles. Curved surfaces can bring new levels of acoustic perfection to a space and can be precisely designed and studied prior to construction, as acousticians add subject matter experts like cold-formed steel framing manufacturers (and their tools) to the project team. The results, as patrons of both Kauffman Center for the Performing Arts and New World Center will attest, can be pitch-perfect.

Chuck Mears, FAIA, is the chief design officer and founder of Radius Track Corporation. He is an expert in the design and fabrication of complex cold-formed steel framing. Mears’ work in 3D computer modeling and fabrication technology allows his team to create cold-formed steel structural systems to support any imaginable architectural form. He can be contacted at chuck@radiustrack.com.

Hello,

I was a foreman at KPAC when it was being built. I actually worked on Helzberg hall and atrium. I have some pictures from the project already. I was wondering if you could please send me yours. I can also send you some of mine if you like. I was very proud to have been blessed to work on such a wonderful project. I wasn’t able to get some of the pictures I needed for my album. Anything you can do would be appreciated.

Thanks Jake

this is so cool thanks