by Mariah Seaboldt, PE

It may seem counterintuitive to study the fire resistance of a combustible material, but wood construction has been the focus of such research for decades. The desire to harness the benefits of wood buildings, while still maintaining a safe environment, has fueled studies into both light-frame wood and mass timber assemblies. The results of this research have informed past building codes and are leading to changes in upcoming ones, allowing more projects to capitalize on the cost, schedule, and environmental advantages of wood construction. As the popularity of wood grows, construction safety practices are also receiving greater emphasis in an effort to mitigate fire hazards during one of the most vulnerable periods of a building’s lifetime.

Overview of mass timber

Light-frame wood construction is common across the United States. However, more projects are now using mass timber in lieu of other building materials. Various types of mass timber products are available, including cross-laminated (CLT), nail-laminated (NLT), glue-laminated (glulam) timbers, and structural composite lumber (SCL). More information regarding typical mass timber elements and common applications can be found in “Mass Timber in North America” by Think Wood.

Mass timber buildings are capable of providing a level of fire-resistance comparable to steel and concrete. As a result, approved changes to the 2021 International Building Code (IBC) introduce additional timber construction classifications (Type IV-A, Type IV-B, and Type IV-C) and will allow three-hour rated mass timber structures to be built up to 18 stories in height (Type IV-A construction). These recently approved changes can be viewed on the International Code Council’s (ICC’s) website.

Images courtesy AKF Group

While there is a growing desire to utilize mass timber, several stumbling blocks stand in the way of widespread use of these products. Due to the predominant use of steel and concrete, designers, owners, and authorities having jurisdiction (AHJs) may not be familiar with the fire research associated with mass timber. Additionally, while the new provisions of 2021 IBC expand on the allowances for mass timber buildings, formal code adoption by individual jurisdictions can be a lengthy process. As a result, the public’s perception of large-scale buildings has been built on a foundation of steel and concrete. Although the concept of tall, mass timber buildings is new, increasing awareness and use of the material can help change this perception.

Wood behavior in fire conditions

In order to understand the different fire-resistance capabilities of light-frame wood and mass timber, designers should understand the basic fire behavior of the material. When exposed to the heat of fire, all wood undergo a thermal degradation reaction called pyrolysis. As wood is heated, the material decays into volatile gases and leaves behind a layer of char. Flaming ignition of wood is actually the ignition of the volatile gases released during the pyrolysis process. For more details on the science of pyrolysis, read the Society of Fire Protection Engineers’ (SFPE’s) Handbook of Fire Protection Engineering.

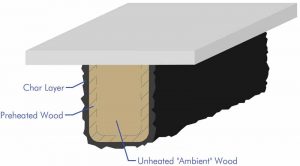

The char layer created during pyrolysis insulates the remaining layers of wood and slows the overall degradation of the member. A portion of the wood directly adjacent to the char layer experiences higher temperatures than the rest of the wood (i.e. preheated zone). As described in the American Wood Council’s (AWC’s) “Technical Report No. 10,” the base of the char layer and the start of the preheated zone are accepted to have a temperature of approximately 300 C (550 F). Beyond the preheated zone, the wood has a temperature close to its initial ambient temperature. This area is usually referred to as “ambient,” “normal,” or “cold” wood. In general, wood members with larger cross sections endure the heat of fire for longer durations, since it takes more time to reduce the size of the ambient zone to the point of critical structural failure.

Basic fire resistance criteria

Whether using mass timber, light-frame wood, or any other material, IBC bases fire-resistance ratings on the testing and exposure criteria of ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials, or Underwriters Laboratories (UL) 263, Standard for Fire Tests of Building Construction and Materials. ASTM E119 is commonly referenced for testing of fire-resistance ratings, though the two standards are effectively the same. IBC permits fire-resistance ratings to be substantiated by subjecting assemblies to ASTM E119 or UL 263 testing, or through calculations, prescriptive designs, or other engineering analysis (IBC 2018, 703.3, “Methods for determining fire resistance”).