by David Nickelson and Jon Bittenbender

Crosslinked polyethylene (PEX) tubing is widely employed across plumbing and heating trades in residential applications, but many specifiers have yet to consider its use in commercial plumbing systems. Based on decades of successful installations and growing confidence in the trade, PEX is gaining ground as a high-performance, cost-effective alternative to copper and chlorinated polyvinyl chloride (CPVC) piping on large-scale commercial plumbing projects.

With more than 50 years of testing and quantifiable performance in applications all over the world, PEX tubing has proven to be a durable material that does not suffer from corrosion, electrolysis, filming, mineral buildup, or water velocity wear—problems plaguing copper and other metal piping systems (read Design Guide: Residential PEX Water Supply Plumbing Systems, Second Edition, [November 2013] from the Plastic Pipe and Fittings Association [PPFA]/International Code Council [ICC]/Plastics Pipe Institute [PPI]/Home Innovation Research Labs).

PEX tubing is manufactured by extrusion in sizes from 6 to 102-mm (1/4 to 4-in.) nominal diameter. It is controlled to outside diameter (OD) dimensions in what is commonly called copper tube size (CTS). The ratio of the OD to the wall thickness of PEX tubing is 9:1 (based on the standard dimension ratio [SDR] of 9).

Advantages of PEX as stated in the design guides of manufacturers include:

- minimization of fittings;

- freeze-break resistance;

- stress corrosion and pitting resistance;

- scale and deposit buildup resistance;

- minimization of noise (water hammer); and

- notching damage and abrasion resistance.

Flexibility matters

The primary advantage of PEX tubing—also available in coils and straight lengths—over copper and CPVC rigid pipe is its flexibility. Installers can route it through walls, floors, and ceilings with minimal fittings. The need for fewer fittings means less resistance leading to reduced pressure loss.

The flexibility of PEX leads to yet another advantage over rigid pipe: freeze-break resistance. PEX tubing expands if it accidentally freezes and returns to its original size when the ice thaws. When water freezes in a rigid pipe, it breaks open the piping and causes leaks and flooding, resulting in a financial headache for the building owner.

Pressure loss and flow rates

To meet standardized pressure ratings, plastic piping requires thicker walls than copper and CPVC, resulting in a slightly smaller inside diameter (ID). The flexibility of PEX offsets this potential ID impact on pressure loss by requiring fewer fittings. As mentioned earlier, fewer points of resistance mean less pressure loss.

Additionally, the development of cold-expansion fittings has helped dispel the myth PEX tubing causes a loss of pressure due to its smaller ID and the use of insert fittings.

Fittings for PEX plumbing systems are available in lead-free brass and polymers in two main styles—cold-expansion and insert. All fitting types must meet the performance requirements of ASTM F877, Standard Specification for Crosslinked Polyethylene (PEX) Hot- and Cold-Water Distribution Systems.

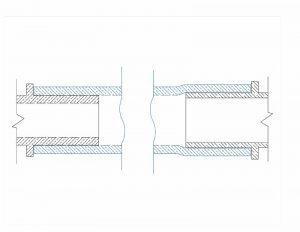

There are two proven technologies for cold-expansion-style fittings, one under ASTM F1960, Standard Specification for Cold Expansion Fittings with PEX Reinforcing Rings for Use with Cross-linked Polyethylene (PEX) and Polyethylene of Raised Temperature (PE-RT) Tubing, and the other referred to as cold-expansion with PEX compression sleeve.

For insert-style fittings, standards include:

- ASTM F1807, Standard Specification for Metal Insert Fittings Utilizing a Copper Crimp Ring,

or Alternate Stainless Steel Clamps, for SDR9 Crosslinked Polyethylene (PEX) Tubing and SDR9 Polyethylene of Raised Temperature (PE-RT) Tubing, brass; - ASTM F2159, Standard Specification for Plastic Insert Fittings Utilizing a Copper Crimp Ring,

or Alternate Stainless Steel Clamps for SDR9 Crosslinked Polyethylene (PEX) Tubing and SDR9 Polyethylene of Raised Temperature (PE-RT) Tubing, polymer; - ASTM F3347, Standard Specification for Metal Press Insert Fittings with Factory Assembled Stainless Steel Press Sleeve for SDR9 Crosslinked Polyethylene (PEX) Tubing, brass; and

- ASTM F3348, Standard Specification for Plastic Press Insert Fittings with Factory Assembled Stainless Steel Press Sleeve for SDR9 Crosslinked Polyethylene (PEX) Tubing, polymer.