Reclaiming steel to save big

by Alana Fossa

![Photo courtesy Nyttend [Public domain] via Wikimedia Commons](https://www.constructionspecifier.com/wp-content/uploads/2020/02/Indian_Mill_Bridge_from_southwest-300x200.jpg)

Steel and zinc: Sustainable building materials

As more architects, engineers, and owners subscribe to the green building movement, an effort to minimize the impact of construction on future generations has become a primary focus for many projects. In line with these goals, the specification of structural steel offers specifiers a high strength-to-weight ratio and low carbon footprint (1.16 tons of carbon dioxide [CO2] per ton of fabricated hot-rolled steel), thereby establishing steel as a popular building material for sustainable development. Further, all steel waste from production, fabrication, and erection is captured and recycled (read More than Recycled Content: The Sustainable Characteristics of Structural Steel by the American Institute of Steel Construction [AISC]).

Images courtesy American Galvanizers Association

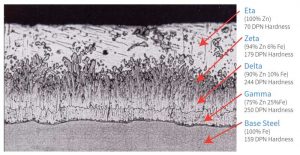

There is an opportunity for additional environmental benefits when steel is hot-dip galvanized for corrosion protection. After fabrication, hot-dip galvanizing (HDG) is a coating process where steel is cleaned and then immersed in a bath of minimum 98 percent pure molten zinc. The result is the formation of a metallurgically bonded zinc coating comprising intermetallic alloy layers covered by a layer of pure zinc (Figure 1). In atmospheric environments, this zinc coating provides durable, maintenance- and emission-free protection for 70 years or more in most regions (Figure 2) (consult Performance of Hot-Dip Galvanized Steel Products in the Atmosphere, Soil, Water, Concrete, and More by the American Galvanizers Association [AGA]). Energy consumption and emissions data measured during zinc production, the galvanizing process, and life cycle of steel were used to conduct a life-cycle analysis (LCA) for hot-dip galvanized steel and demonstrate the environmental impact from production to end-of-life (Figure 3) (refer to Hot-dip Galvanizing for Sustainable Design by AGA). Over the life cycle, the use of HDG is unique because all material and energy inputs and emission outputs are isolated to the production phase because there are no emissions or maintenance after installation (refer to Hot-dip Galvanizing for Sustainable Design by AGA).

HDG can not only provide benefits in terms of lower environmental impact during use, but also allows steel to be reused or recycled efficiently for other projects at the end of its life. At end-of-life, both steel and zinc are recycled without waste or the loss of any physical or chemical properties. This means rather than being down-cycled into other or lesser products, zinc and steel can be reused again and again without compromising structural integrity (read Life-Cycle Assessment study for hot-dip galvanized balcony system compared with painted balcony system by S. Vares, K. Tattari, and T. Hakkinen). Also, steel has the highest recycled content of any building framing material at 93 percent, and 98 percent of all steel is currently being recycled (read More than Recycled Content: The Sustainable Characteristics of Structural Steel by AISC). Similarly, zinc has a high reclamation rate of 80 percent in North America and 95 percent in building projects (consult Zinc: A Sustainable Material Essential for Modern Life by the International Zinc Association [IZA]).