by Kari Moosmann

For many years, designers and contractors have espoused tilt-up construction for providing a more airtight building envelope than competing wall assemblies, such as wood and metal stud wall, metal siding, and concrete and brick masonry. Now, code language may also be a supporting factor.

Air barrier requirements have become part of the 2012 version of the International Energy Conservation Code (IECC), which demands performance testing of airtightness when approved construction assemblies or materials cannot be demonstrated. Once adopted by state and local code officials, all commercial buildings will need to comply with these requirements, including the ability to meet air leakage testing and verification parameters.

Jim Baty, technical director for the Tilt-up Concrete Association (TCA), says the new energy standards will have significant impact.

“At first glance, this new layer of performance seems a herculean task to deliver in the complex world of building construction,” he explains. “However, building technologies such as tilt-up concrete construction have decades of performance track records demonstrating the successful combination of envelope performance consistency and complex form and aesthetics. This is now essential to bring the elusive resolution to higher energy standards into reality for a culture seeking more complex and visually appealing building façades.”

Image courtesy ICC

Tilt-up basics

To understand the possibilities of using tilt-up to deliver heightened energy and air-barrier performance, one must look no further than the basics of the construction method. (For more on the topic, see TCA’s resource volume, The Construction of Tilt-up. Visit www.tilt-up.org.) The term itself was coined in the late 1940s to describe a method for constructing concrete walls rapidly and economically without the formwork necessary for poured-in-place walls.

Tilt-up (also known as ‘tilt-wall’ or, in many specifications, ‘site-cast precast concrete walls’) is

a two-step process. First, slabs of concrete that will comprise wall sections are cast horizontally on the building floor slab or separate casting slab.

Then, after attaining sufficient strength, they are lifted (tilted) with a crane and set on prepared foundations to form the exterior walls. The erected panels are temporarily braced, but not typically connected to one another. The roof structure is then attached to the walls, the braces are removed, joints are caulked, and the wall finishes are applied to complete the building shell.

Several features make the tilt-up construction method unique. The panels are generally handled only once; they are lifted or tilted from the casting slab and erected in their final position in one continuous operation. Tilt-up panels tend to be of such large size and weight they can only be constructed onsite and in close proximity to their final location in the structure. Panel gravity loads are supported directly by the foundation instead of being supported by a structural frame. Typically, the panels are erected before the structural frame. They are usually load-bearing for gravity loads and lateral loads.

Tilt-up concrete is a unique form of precast construction and, as such, has its own specialized set of design parameters and construction techniques.

Looking at the language

A close examination of the 2012 IECC reveals the significant changes for both air barriers (C402.4–“Air Leakage Mandatory”) and thermal envelopes (Sections C402.4.1 through C402.4.8). The key components found in each of these sections that have significantly strengthened the code’s impact also deliver the final step of an initiative to reduce building energy performance in the United States by 30 percent over previous energy standards.

Section C402.4.1, “Air Barriers,” states:

A continuous air barrier shall be provided throughout the building thermal envelope … [and] … the air barrier shall comply with Sections C402.4.1.1 and C402.4.1.2.

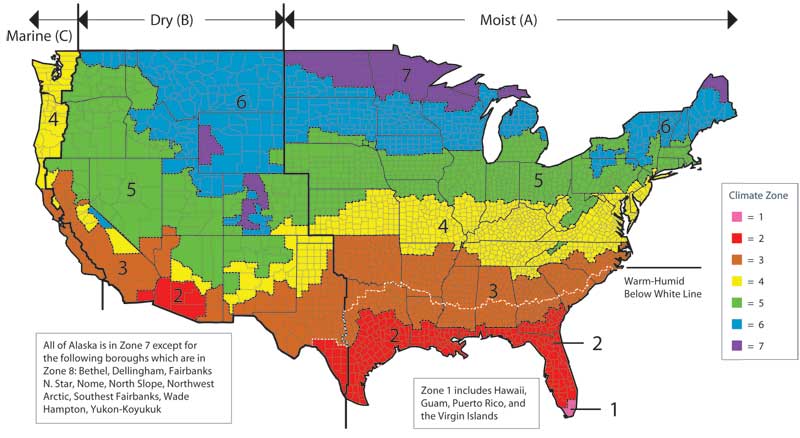

This section is applied for all buildings under the jurisdiction of the code located in climate zones 4 and higher. As such, the air barriers are permitted to be located on the inside or outside of the building envelope, as well as within the assemblies composing the envelope (or any combination thereof). Therefore, selection of the building envelope construction may largely be determined by the effectiveness of achieving the continuous air barrier—otherwise, the structure may incur significantly higher costs of construction to detail for the required performance.

It sounds to me like it is a similar idea to framing a house with wood. You build the frame ant then lift it and secure it into place. It is just easier to build walls on the ground. So, I am all for using tilt up construction. If it is easier and faster then why not?

Great post!!! Thanks for sharing this information with us…