Understanding highly insulated wall assemblies’ relationship with global warming

by Jim Lambach

A well-insulated building envelope is the starting point in any energy conservation strategy. The embodied global warming potential (GWP) of the insulating material, as part of a complete wall assembly, must be weighed against the use-phase energy efficiency contribution to see the complete environmental picture. This article examines the impact of both high- and low-embodied GWP insulation materials on the ultimate benefit of highly insulated wall assemblies.

Global warming potential is a data point frequently considered when selecting building materials, including insulation. It is typically expressed only as output—greenhouse gases (GHGs) emitted during the material’s manufacturing, installation, use phase, and disposal. What is rarely taken into account is the prevention of GHG emissions due to use-phase energy efficiency. This is especially true when the material is measured in its installed state as part of a complete system. Understanding the holistic energy savings measurement will be increasingly relevant as the industry continues to embrace long-term resilience when creating new buildings.

This article compares two highly insulated R-38 assemblies—one a low-embodied GWP wall that contains fiberglass insulation between framing, with polyisocyanurate (polyiso) as the continuous insulation (ci) layer, and another higher-embodied one that contains closed-cell sprayed polyurethane foam (ccSPF) between framing, with polyiso again used as the ci layer. By taking a simplified approach for estimating heat transfer across the functional unit (instead of the whole building) in the use-phase, it becomes straightforward to calculate the overall GWP benefit of a highly insulated wall assembly.

As this article demonstrates, even in the case of the higher GWP wall assembly, the payback (i.e. time required for in-use GWP conservation to equal the cradle-to-grave embodied GWP of the insulation) is reached in a short time relative to the building’s service life. Perhaps surprisingly, the high GWP wall assembly is in GWP conservation mode for 95 to 98 percent of its service life. It is findings like this, when the data is clear and comprehensive, that architects and builders can use to design for resilience.

Understanding EPDs and LCAs for appropriate data input

Environmental product declarations (EPDs) have been published for numerous insulation materials. A required output from the EPD is the list of environmental impacts, which are reported on the basis of a common functional unit, enabling comparison of different types of insulation materials. Insulation EPDs may also include a whole building use-phase analysis of energy savings.

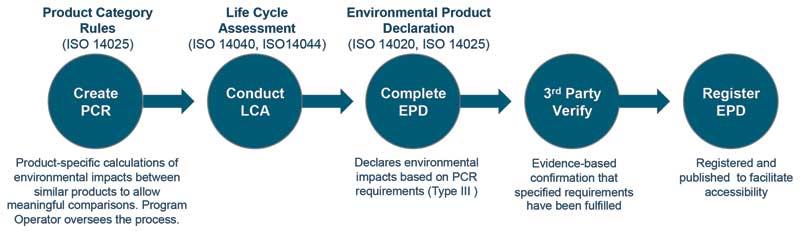

In the big picture, EPDs are a disclosure tool developed by product manufacturers to assist building designers in better understanding a product’s environmental impact so they can make more informed product selections. The basic steps to create an EPD are shown in Figure 1.

EPDs are developed after the product lifecycle assessment (LCA) is conducted, and are based on the applicable product category rules (PCR) that ultimately enable all products within a category to be compared by creating data consistency, regardless of manufacturer. The format of the EPD also provides a simple, consistent summary of environmental impacts.

The EPD process is prescribed by International Organization for Standardization (ISO) standards developed using a consensus process with multiple stakeholders. Groups overseeing development of EPDs and/or offer listing and registration services include ASTM, UL, International Code Council Evaluation Service (ICC-ES), PE International, SCS Global Services, and NSF International.

EPDs and/or LCAs are currently available for a variety of insulation materials:

- polyiso foam board;

- ccSPF;

- extruded polystyrene (XPS);

- fiberglass; and

- mineral wool.

PCRs for thermal insulation

Product category rules describe reporting requirements for consumption of material resources and primary energy, as well as cradle-to-grave environmental impacts for a product category such as thermal insulation. The PCR applies to all of the commercially available thermal insulation products, regardless of type.

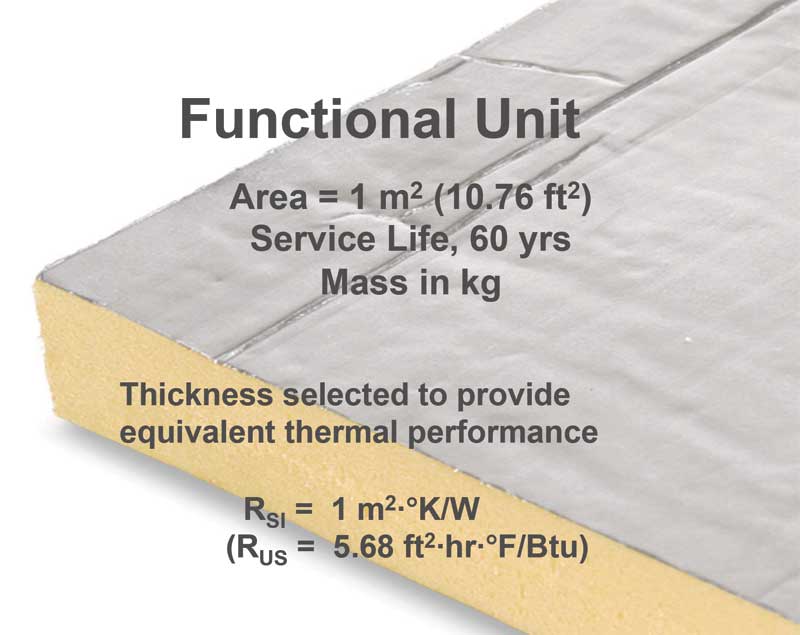

The PCR for Building Envelope Thermal Insulation is listed on the UL website (Visit the site ul.com/global/documents/offerings/businesses/environment/PCRs/ULE_PCR_EnvelopeThermalInsulation.pdf); it defines the thermal insulation functional unit, as illustrated by Figure 2. The PCR states the following limitation in its “Goal and Scope (v1.2, Section 1.0):”

This is not intended to be a full building LCA, therefore, the installation phase impacts do not address the energy savings that result from the ongoing building operation due to the installed insulation.

In Section 5.2.4, it then provides the following option (with a section underlined by this author for emphasis):

During its service life, insulation significantly reduces the energy use in a building, thereby reducing the impact on the environment. The exclusion of the building heating and cooling during the insulation material’s use phase severely underestimates the benefits that insulation has on the environment. This section may describe the energy savings and environmental benefits during use of the product in a building and only references operational consideration.

Environmental impact reporting in thermal insulation EPDs

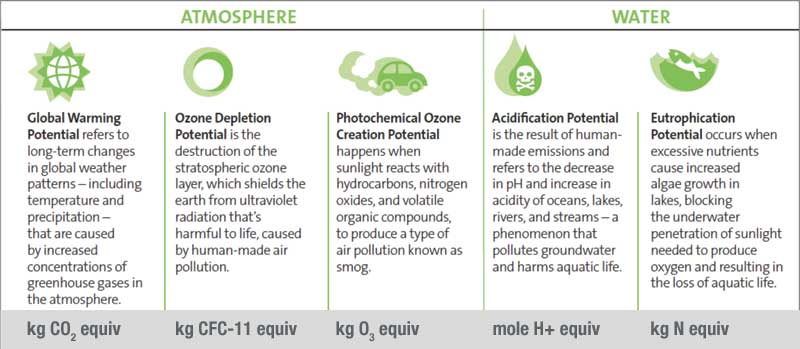

As environmental impacts are reported on the basis of the functional unit (rather than on a whole building), it is not a straightforward exercise to create comparisons between the environmental impacts and the use-phase energy savings from one insulation material to another. Figure 3 describes the five environmental impacts reported in the insulation EPD, and the units used to report their impact (per functional unit). The first one is the focus of this article—GWP—which is the environmental attribute creating the most dialogue in today’s environmental building conversation.

Other impacts like ‘ozone depletion potential’ (ODP) were a huge issue in the 1980s and 1990s. First-generation blowing agents for ccSPF and polyiso had high ODP values, and the industry solved the problem by converting to second-generation agents in the early to mid-90s.

‘Photochemical ozone potential’ refers to smog, which is not the clamoring issue it once was since the nation converted to cleaner burning fuels. ‘Acidification potential’ is a product’s tendency to contribute to acid rain, while ‘eutrophication potential’ is its tendency to contribute to algae growth (thus harming aquatic life).