FAILURES

FAILURES

Deborah Slaton, David S. Patterson, AIA, and Jeffrey N. Sutterlin, PE

When specifying and installing air and moisture/vapor barriers, consideration is often given to cold-weather limitations of those materials to better ensure proper application and long-term performance. While this is particularly true for projects in cold climate zones, it can also apply to hot and mixed climate zones when application of these materials is anticipated to occur during the winter.

Self-adhering and fluid-applied membranes (as well as accessories such as primers, mastics, and sealants) typically have low-temperature application limits. Therefore, many manufacturers offer low-temperature versions of their products. Low-temperature restrictions typically apply during the material’s application (and in some cases, curing), but do not normally apply to their post-application, in-service conditions.

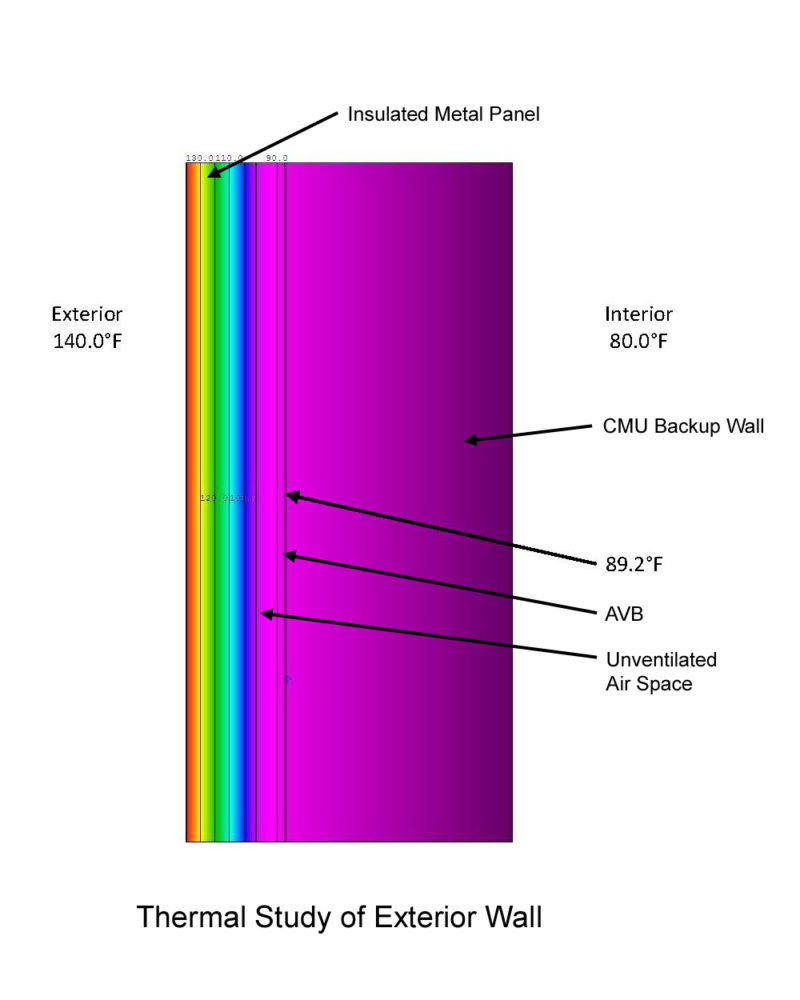

A simple two-dimensional thermal study of an exterior wall at a mechanical penthouse clad with light colored insulated metal panels illustrated that the temperature at the exterior face of the CMU backup wall (32 C [89 F]) was considerably less than the 70-C (160-F) nominal in-service temperature of the AVB. (Note that 60 C [140 F] is the assumed temperature of the metal face of the panel.)

Image courtesy WJE

The limitations of product installations performed in warmer climates and/or summer months should be fully understood, as product materials (e.g. primers) and installation methods may change under these conditions. As an example, fluid-applied membranes may experience changes in viscosity at high temperatures, requiring adjustments to the application method and equipment for a more uniform and consistent coating thickness; keeping product storage containers out of direct sunlight can reduce the potential for unwanted heat buildup.

In addition to elevated temperatures during installation, conditions vulnerable to heat buildup during the service life of the building should be evaluated to determine whether a product can accommodate long-term exposure to elevated temperatures. Consideration should be given to the anticipated temperature of the exposed surface depending on the projected exposure (and length of exposure) to solar radiation, noting darker surfaces absorb more heat than lighter surfaces. The location of a thermal control layer relative to the product in question should also be taken into account. A product located inboard of an adequate control layer will be less influenced by exterior conditions than one located outboard of a thermal control layer.

On a recent project, thermal studies of the wall assembly were performed and reviewed with a technical representative of the membrane manufacturer to assist in understanding conditions the air/vapor barrier (AVB) could experience while in service. Use of insulated metal panels (IMPs) as a cladding resulted in limited heat buildup within the wall cavity due to the insulated core of the panels. In contrast, use of dark-colored uninsulated metal panels, without insulation inboard of the panel and with no ventilation of the air space between the panel and AVB, resulted in heat buildup within the wall cavity—with the AVB reaching temperatures close to the high-temperature service limits of the material. As illustrated by this example, the design and actual in-service conditions of exterior walls should be considered when selecting a suitable barrier for the wall assembly.

The opinions expressed in Failures are based on the authors’ experiences and do not necessarily reflect those of the CSI or The Construction Specifier.

Deborah Slaton is an architectural conservator and principal with Wiss, Janney, Elstner Associates (WJE) in Northbrook, Illinois, specializing in historic preservation and materials conservation. She can be reached at dslaton@wje.com.

David S. Patterson, AIA, is an architect and senior principal with the Princeton, New Jersey, office of WJE, specializing in investigation and repair of the building envelope. He can be contacted at dpatterson@wje.com.

Jeffrey N. Sutterlin, PE, is an architectural engineer and senior associate with WJE’s Princeton office, specializing in investigation and repair of the building envelope. He can be reached at jsutterlin@wje.com.