By Ryan Shure

It is easy to dismiss painting and sealing as “final touches” of a construction project. However, while they may be surface-level in appearance, they play a critical role in protecting a building from the elements and fortifying the building envelope. This guide will break down various paint and sealant application techniques and discuss their critical role in promoting the structural integrity of a building.

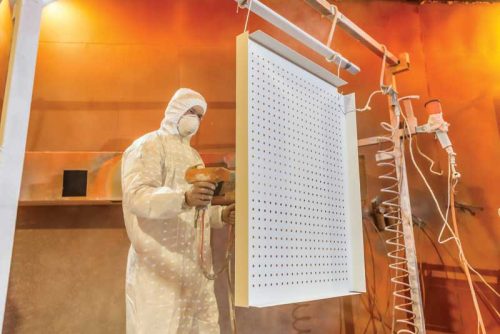

Spray painting techniques

Spray painting is the most common technique at a manufacturer’s or contractor’s disposal. It is highly versatile and can be used on material components or entire building walls. It also tends to be the most economically viable painting technique, as applicators dispense at pre-calibrated rates. There are several types of spray painting applications, each with its unique qualities and uses.

Air-atomized spray

This is the most conventional spray painting method. The applicator on a traditional spray gun combines compressed air with flowing paint to create a pressurized mist that coats the building wall or material surface. It can be used on any type of substrate, helping protect the structural integrity of wood, steel, and masonry buildings alike. The downside to air-atomized techniques is a loss of paint due to overspray and blowback. However, this poor transfer efficiency is often offset by lower labor costs, as it does not require specialists to operate air-atomized applicators.

Airless spray

This spraying method forces paint through a narrow opening to create pressure. The paint particles are then projected at a lower velocity than those used in an air-atomized applicator, resulting in greater transfer efficiency and less paint loss. The drawback to airless spray applications is more expensive equipment to purchase and maintain. It also requires greater skill and experience to successfully use airless spray equipment, resulting in higher labor costs.

Electrostatic spray

This is the most technologically advanced and efficient spray painting application. The equipment charges negative paint particles at a high voltage, causing attraction to the building’s surface for improved transfer efficiency over other spraying methods. This makes it the best spraying option for tough corners and other hard-to-reach areas of the building. It gives the surface a smooth, solid coat with minimal effort. Although this is the most efficient spraying method, it does require a high level of skill to ensure safe application.

Electrostatic painting carries a higher fire hazard than other spraying applications and requires the use of paints with specific chemical compositions for charging, eliminating many of the mass-produced paints on the market.

Paint rolling and brushing

Although rolling and brushing may be considered “old fashioned” painting techniques, they do have some use for small areas where setting up a spray system is not worth the time. Depending on the spray system available to the project, brushing may also be the only means of guaranteeing adequate application to recessed nooks or other hard-to-reach areas. Finally, rolling and brushing may be the safest choice in poorly ventilated areas, as airborne chemicals from air-atomized spray applicators can be hazardous without the proper exhaust infrastructure.

When using a roller or brush to apply paint, success largely depends on the skill of the painter and consistency of the paint. Thin paint will not cover the surface adequately, while thicker paints can pool and clump. The risk of a lower quality finish with rolling and brushing means preparation is also critical to adequately protect the structure. Before applying a layer of paint, be sure the surface is scraped and cleaned with a high-quality paint stripper1 to give the fresh coat the best chance of adhesion.

Paint dipping

As its name implies, dipping involves fully submerging an object into a pool of paint. It is commonly used for adding primer to building materials and ensuring all angles of corrugated surfaces are adequately coated. Dipping is not an option for painting an entire building or large materials, but it can be useful for adequately coating small components. It is generally part of the equation when painting a structure—not the entire solution.

Proper sealant technique

Sealants offer a higher level of protection to gaps and joints than paint can provide by itself. They are essential for keeping air, moisture, and other corrosive agents out of the building envelope. The success of a sealant application will depend heavily on the skill and technique of the administrator. There are several key steps to ensuring a successful sealant application:

- Clean surfaces and joints—sealants adhere best to surfaces free of debris. In addition, clean surfaces give the professional a better view of the working area.

- Priming—it is important to know the sealant type because some advanced products can work at full capacity without a primer. For those that need priming, use a lint-free cloth to evenly apply the primer and prevent over-application. Use a brush to get primer into joints and other hard-to-reach areas.

- Shooting—this is the sealant application process where the material is applied to the surface or between and across joints. The success of the application requires coating and filling all necessary features to ensure structural integrity. Be sure to tool the sealant before it cures to guarantee it properly adheres to the object’s shape.

Without the proper sealing technique, not only does the structure face an increased risk of corrosion, but the project runs the risk of expensive callback scenarios to rework the inadequate application.

Enhance structural integrity

Painting and sealing are critical components manufacturers and contractors must consider for protecting the structural integrity of their projects. In most cases, choosing the correct application method and using deft technique is the difference between a successful and an inadequate job.

Notes

1 To learn more, visit prosoco.com/products/hard-surface-care/paint-removers/.

Author

Ryan Shure is a freelance writer who loves sharing his knowledge and expertise on renovations and construction. He lives in Tampa, Fla., where he enjoys spending time with his wife and researching building material trends in his free time.