By Jason T. Cavanaugh and Michael “Mick” Dunn

Today’s facility owners and managers face more intense demands than ever, driven by challenges such as tighter budgets, compressed timelines, and the need to create and maintain spaces that attract the right customers while promoting greater employee productivity.

These same demands extend to specifiers tasked with meeting every expectation for new construction or renovation projects. One critical consideration is occupant comfort, a concept that has evolved beyond ensuring a space is neither too hot nor too cold. Today, several dynamic factors play a significant role:

- Climate change impacts: Regions are increasingly experiencing extreme heat, and some climate zones now require air conditioning installations where they previously did not. Harsher winter storms and persistent droughts are also becoming more common.

- Heightened focus on indoor environmental quality (IEQ): Factors such as room temperature, acoustics, cleanliness, and air quality are now central to occupant health, happiness, and productivity.

- Aging HVAC equipment: Many facilities, particularly K-12 schools, are struggling with outdated equipment that operates inefficiently.

- Tighter budgets: Economic pressures are driving many facility owners and managers to find innovative ways to do more with less.

- The vision of a net-zero carbon world: Businesses and communities are pursuing aggressive goals to achieve a net-zero carbon footprint.

- Stewardship of the planet: There is an increasing emphasis on reducing energy consumption and minimizing the waste of natural resources, such as water.

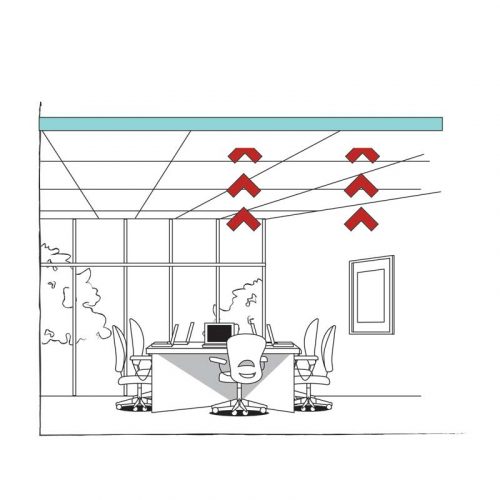

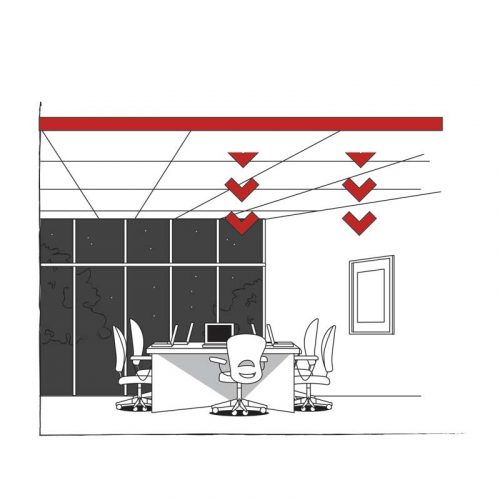

The recent innovation of integrating phase change material (PCM), a well-established technology, into ceiling panels has generated significant interest. It is already proving its capability to address many of the challenges identified above. Simply explained, PCM in a ceiling panel helps maintain a consistent and comfortable temperature of 22 C (72 F) by passively absorbing heat when room temperatures rise and releasing it when the space cools.

Central to conversations about PCM ceilings is their ability to reduce energy consumption significantly by offsetting HVAC demand during peak hours when mechanical heating and cooling are at their least efficient. For example, a ceiling composed of a mineral fiber panel that uses PCM technology can reduce energy costs and decrease consumption by up to 15 percent (according to measured cooling energy savings in lab tests).1 While the energy savings potential of PCM ceilings is paramount, the whole story lies in their multifaceted impact, enhancing acoustics through sound blocking and absorption, simplifying installation processes, and contributing to broader environmental sustainability goals.

Thermal mass

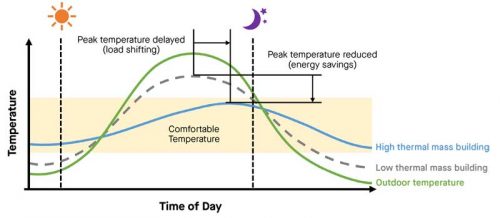

As climate change continues to drive extreme weather events, there is an increasing emphasis on enhancing the resiliency of the built environment. One effective way to achieve this is by using thermal mass, which refers to a material’s ability to absorb, store, and release heat energy. By passively moderating indoor temperature fluctuations, thermal mass helps make building structures more resilient to heat waves and power outages. Concrete, brick, and stone have high thermal mass, absorbing and releasing substantial amounts of heat. These thermally massive materials function as buffers, smoothing out the daily temperature cycles inside buildings by absorbing heat during the day and releasing it in the evening.

Building thermally massive structures can be accomplished through strategic material selection for both the exterior and interior of a building. For example, stone or tile floors and granite countertops contribute to maintaining interior temperature control. Additionally, lesser-known interior solutions, such as water-filled containers, and emerging technologies, such as PCM, are increasingly being explored to enhance the thermal resilience of buildings further.

Increasing the thermal mass of buildings can play a crucial role in advancing sustainability initiatives by mitigating the carbon emissions that have contributed to global warming and extreme climate events over many decades. Buildings with high thermal mass can passively cool and heat interior spaces, reducing the strain on mechanical HVAC systems and, in turn, decreasing energy consumption (Figure 1, page 10). Moreover, thermal mass functions like a battery; it can be “charged” when renewable solar or wind energy is available, and then that energy can be “discharged” during peak hours to lessen the reliance on carbon-intensive power plants.

According to the Environmental Protection Agency (EPA), in 2021, fossil fuels remained the most common fuel for electricity production in the United States.2 As of 2019, burning coal, natural gas, and oil for electricity and heat was the single-largest source of global greenhouse gas emissions.3 By decreasing the use of HVAC systems and optimizing their usage time, increased thermal mass can help lower carbon emissions.

Today, legislation such as the 2022 Inflation Reduction Act underscores the importance of thermal storage technologies. Among other initiatives to accelerate the clean energy transition, the act incentivizes strategies such as increasing thermal mass in buildings to help flatten the load on an electrical grid that relies more and more on intermittent renewable energy sources.

Lastly, while the importance of thermal storage strategies is on the rise, some of the inherent issues in high thermal mass materials make them less attractive. Production of cement, the key component of concrete, emits a significant amount of CO2, contributing to approximately seven percent of global emissions.4 Moreover, the large weight and volume of conventional materials used for thermal mass make them difficult to transport, slow to build with, expensive, and impractical for retrofitting into existing buildings. The door has been opened for science and technology to increase thermal mass in buildings through better, sustainable solutions that meet modern desires and requirements for building operations and environmental responsibility.

PCM ceilings and thermal mass

Using PCM for thermal control is not a new concept, with ice in a cooler being a familiar example. As ice absorbs energy (i.e. heat) inside the container to keep its contents cool, it changes into a liquid state. If that liquid is exposed to an environment of 0 C (32 F) or lower, it will reverse the process, releasing heat and returning to its solid (ice) state.

Hidden discretely in the ceiling panel, PCM acts similarly to ice in a cooler. PCM in the ceiling panels absorbs and releases heat as it changes phase in response to fluctuations in air temperature. As a space warms—typically during the day when it is occupied or receives sunlight—the crystalized PCM gradually dissolves, absorbing heat and cooling the space. The stored heat is released into the space as the room cools at night or during low-occupancy times, and the PCM re-crystalizes. The PCM in ceiling panels is engineered for maximum performance around a comfortable 22 C (72 F) (Figures 2A and 2B).

Introducing PCM ceilings to a building or space presents an easy, efficient way to increase thermal mass, especially considering other options such as brick, concrete, or stone. Compared to these conventional thermal mass materials, PCM ceiling panels have a more concentrated storage capacity, are thinner, and are more thermally conductive—allowing heat storage and release to occur more readily. Moreover, because almost every space needs a ceiling, PCM ceiling panels can increase thermal mass without adding another element to the building or room.

In theory, a building can be made more thermally massive by, for example, strategically building a brick divider in a room; however, this will change the function and overall design and can be labor intensive. On the other hand, PCM ceiling panels are easy to install—a single person could replace old panels using little more than a ladder. To illustrate these advantages, consider that the PCM in a lightweight mineral fiber ceiling panel can have more than 10 times the energy storage density of brick.5

Energy savings

As mentioned, lab tests show that PCM ceilings can improve energy savings by as much as 15 percent by providing up to 35 BTU per square foot of passive cooling.6 PCM ceilings also offer several other benefits, many stemming from their primary advantage of being able to regulate thermal comfort naturally. By absorbing and releasing heat, PCM ceilings help maintain stable indoor temperatures and even reduce peak indoor temperatures during extreme events such as heat waves and “cold snaps.” In doing so, PCM ceilings help lower the demand for mechanical HVAC equipment. To follow are several categories of PCM ceiling advantages, with key benefits related to each:

Less demand for HVAC systems and lower energy consumption

- Pre-cooling or pre-heating strategies can be developed with PCM ceilings to reduce the burden on HVAC systems during peak hours.

- Passive PCM heating/cooling can continue thermal management during power outages.

- PCM ceilings can maintain comfort in changing climates or environments with daily hot-cold fluctuations without additional energy costs.

Flexibility

- Allow economical “spot managing” thermal comfort in areas—such as attics or older annexes—that experience more drastic temperature swings than other parts of a building.

- Enable room-by-room upgrades as budget allows.

- Offer temperature stabilization and prevention of overheating/overcooling inefficiencies in spaces that often require heating in the morning and cooling in the afternoon.

Budget friendliness

- Offer a budget-friendly option for buildings in climates requiring air conditioning for fewer than 20 days during the year.

- Leverage existing assets through retrofit or new-ceiling investment to improve environmental comfort and energy savings with minimal incremental cost.

- Provide an economical alternative when the budget does not allow HVAC system retrofits or replacement.

- Have a low price of entry. PCM ceilings do not require an increase in a building’s physical footprint, structural work/changes, mechanical installations, or electrical engineering.

Labor-saving

- Maintenance-free, unlike mechanical heating/cooling equipment.

- Non-labor intensive, with a relatively fast installation that a building’s maintenance staff can do.

Environmental

- Reduce carbon footprints plus lower energy expenditure and wear-and-tear on equipment.

- Help mitigate challenges—including budgetary and increased strain on HVAC infrastructure—of building electrification.

- Fit into the thermal comfort portion of the WELL Building Standard and can contribute to energy and atmosphere credits for LEED.

In addition, because the PCM in ceiling panels is basically composed of natural, inorganic materials, including salt and water, they are nonflammable and safe for use in buildings. The raw materials can be sourced domestically and are plentiful, allowing for the scaling of the technology.

Lastly, topping the list of PCM ceiling advantages are acoustical benefits. While occupant comfort is certainly a priority of IEQ, a recent study by the University of California Berkeley reports noise, specifically speech intelligibility and speech privacy, is the most prevalent source of occupant dissatisfaction in the workplace.6 PCM ceiling panels support better acoustics in two ways. First, the PCM technology can be blended with acoustic sound-absorption and sound-blocking ceiling panel technology. Secondly, the PCM can improve a ceiling’s sound-blocking performance, reducing noise transmission to adjacent areas.

Who can benefit from PCM ceilings?

While almost any building type in a vast array of climate zones can find advantages to installing PCM ceilings, these are six main categories warranting strong consideration of using the technology:

Regions with significant diurnal temperature ranges

In dry climates with hot days and cool nights, PCM ceilings—enhanced by strategies such as night ventilation or simply opening windows—can naturally absorb heat during the day and release it at night with little or no energy expense.

Regions with high energy costs

Building operators in jurisdictions that face high peak-demand charges due to thermal loads on energy grids can realize significant financial benefits from PCM ceilings’ energy savings. Building owners can also take advantage of time-of-use rate structures with PCM by pre-cooling the building during hours when electricity is less expensive, allowing the building to maintain passive comfort during high-rate hours.

Buildings where comfort, productivity, and resilience during outages are crucial

This includes offices, schools, healthcare facilities, and data centers. PCM ceilings are particularly effective in spaces with direct sunlight, high occupancy, and other intermittent heat sources that cause significant temperature swings.

Older buildings with aging HVAC systems or no air conditioning

According to energy.gov, commercial buildings waste up to 30 percent of the energy they consume.7 This is primarily due to outdated equipment and inefficient use of lighting and HVAC systems. PCM ceilings can boost efficiency and provide a pre-charged “bank” of cooling to help outdated HVAC systems keep up during the hottest hours.

Management systems scheduled to ventilate at night based on prevailing weather

These systems can optimize operations to leverage the thermal storage capacity of PCM ceilings, enhancing overall performance.

PCM ceilings—at work and commanding attention

Integrating PCM technology into mineral fiber ceilings is drawing the attention of communities and government agencies dedicated to improving building energy efficiency. It is already demonstrating its value in real-life applications. This past summer, a proprietary PCM mineral fiber ceiling product was included in the U.S. General Services Administration’s Green Proving Ground (GPG) program. GPG introduces emerging technologies from the private sector into federal buildings, demonstrates their effectiveness, and publishes information about these technologies to help advance American-made clean energy technologies and accelerate their use in public and private sectors.

In a controlled laboratory study, the performance of these ceiling panels with PCM was evaluated to demonstrate their load-shifting and temperature-moderating effects in a room-scale chamber. The study found that after pre-cooling, the 33 PCM ceiling panels absorbed approximately 4,000 BTU of heat generated in the room during the day. This significantly reduced daytime cooling energy, achieving about a 20 percent reduction in the rate of air temperature change during the day. This was ascertained by comparing scenarios with PCM-enhanced ceilings and standard acoustical ceilings, showing that the PCM scenario delayed the need for air conditioning by nearly two hours.8

In addition, the same PCM ceiling panel products were installed in the Raymond Frye Community Building in Wellington, Kans., as part of a validation study conducted with the U.S. Department of Energy (DOE) Office of Energy Efficiency and Renewable Building. The building is the first community building in the country to use these ceiling panels. Data from the three-year study, awarded in 2021, will be analyzed and published in late 2024 by the National Renewable Energy Laboratory (NREL). The study stands to help drive adoption and scale for broad commercial use of innovative building technologies focused on improving energy efficiency, demand flexibility, and building-to-grid capabilities.

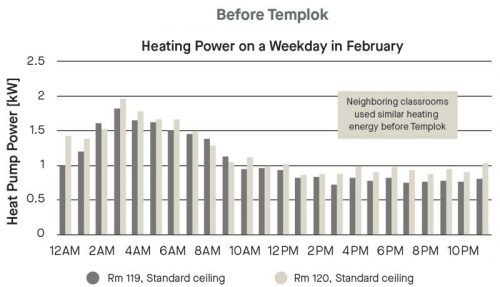

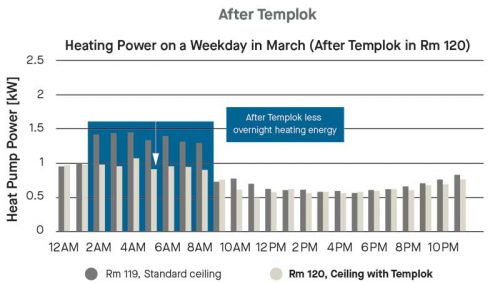

Further, in New Hampshire, a high school facing high overnight heating costs during the school year installed the same mineral fiber ceiling products with PCM in two classrooms. Baseline heating energy in four classrooms was monitored for several months to assess if the technology would effectively reduce high energy consumption for heating during winter and spring nights. All four classrooms were in the same wing and of similar size and function, and each was primarily heated by an individual split heat pump system inside the room. The PCM ceiling panels were deployed in one upstairs and one downstairs classroom—with the original ceiling panels remaining in the other two rooms for comparison. Across several analysis techniques, during winter nights, the classrooms with the PCM ceilings saw a 5 to 9 percent decrease in energy use compared to the control rooms (Figures 3A and 3B).9

Conclusion

According to the National Oceanic and Atmospheric Administration (NOAA), the 10 warmest years on record all occurred in the past decade, with 2023 being the warmest year on record for North America, South America, and Africa, as well as the second warmest for Europe.10 Facilities are facing unprecedented challenges as climate change continues to warm up winters, heat up summers, and drive extreme weather events. These challenges range from heat-driven closures of schools that historically did not need cooling systems to elevated pressure on businesses to reduce their carbon footprint to remain competitive and compliant.

Although PCM technology has existed for some time, its integration into ceiling panels offers an exciting new solution for increasing the sustainability and resiliency of the built environment. This is due to their ability to increase a building’s thermal mass in ways that overcome modern challenges for facility operators, specifiers, architects, designers, and contractors responsible for ensuring that new construction and renovations maximize every opportunity to create beautiful, functional, and sustainable spaces.

By improving energy efficiency and IEQ, mineral fiber ceiling panels with PCM enhance the bottom line and align with today’s mandatory sustainability objectives—supporting occupant well-being and productivity while helping to move the world toward a net-zero carbon future.

Notes

1 Learn more at armstrongceilings.com/content/dam/armstrongceilings/commercial/north-america/technical-guides/templok-technical-guide.pdf.

2 Refer to the Electric Power Sector Basics at epa.gov/power-sector.

3 Review the global greenhouse gas (GHG) overview at epa.gov/ghgemissions.

4 Read “Everything You Need to Know About Embodied Carbon” at carboncure.com/concrete-corner/everything-you-need-to-know-about-embodied-carbon/.

5 See note 1.

6 Visit cbe.berkeley.edu/research/occupant-survey-and-building-benchmarking/.

7 Learn more at energy.gov/eere/buildings/about-commercial-buildings-integration-program.

8 See note 1.

9 See note 1.

10 Refer to climate.gov/news-features/understanding-climate/climate-change-global-temperature#:~:text=Highlights,0.20%C2%B0%20C)%20per%20decade.

Authors

Jason Cavanaugh is a mechanical engineer at Armstrong World Industries in Lancaster, Pa., specializing in developing energy-efficient building products. Cavanaugh is a member of ASHRAE T.C. 6.9 Thermal Storage and ASTM International. In 2024, he presented a conference paper on an experimental assessment of phase change material (PCM) ceiling tiles for cooling load management. He can be reached at JTCavanaugh@armstrongceilings.com.

Michael “Mick” Dunn, technical sales manager at Armstrong World Industries, is passionate about developing and deploying products and solutions incorporating Phase Change Materials (PCM) in the construction industry. His 20 years of construction management experience include being the founder/owner of the Maine-based Shift Energy, LLC, which specializes in large-scale commercial solar heating systems. In 2015, Dunn co-founded Insolcorp, LLC, and continues to focus on the need and interest for dynamic ways to store thermal heat and improve the sustainability and resiliency of the built environment. He can be reached via email at MRDunn@armstrongceilings.com.