by Ram Mayilvahanan

In the push to forge more energy-prudent buildings, design professionals are leaving no part of the envelope unexamined. Walls and roofs have always presented a clear target for better thermal performance. Somewhat less obvious are surfaces that are out of sight—below-grade foundation walls and floor slabs. Well-engineered insulation in these locations can provide significant energy savings.

What separates below-grade insulation types from one another? Moisture retention, R-value stability, and compressive strength are the key performance attributes to consider when evaluating and comparing different below-grade insulations.

Installing thermal insulation on below-grade foundation or perimeter walls and under slabs is important because un-insulated concrete provides a thermal and moisture bridge between the heated building interior and the relatively cooler earth surrounding the building, or through exposed slab edges to the outside air.

The U.S. Department of Energy (DOE) estimates insulating the exterior edge of slabs in slab-on-grade buildings can reduce winter heating bills from 10 to 20 percent.1 Likewise, the lack of insulation on below-grade foundations, crawlspaces, and under slabs accounts for up to 25 percent of a structure’s total energy loss, the Expanded Polystyrene (EPS) Industry Alliance reports.2

In addition to saving energy, installing thermal insulation on foundations and slabs helps:

- improve comfort in below-grade and daylight basements;

- reduce interior condensation on foundation walls; and

- protect concrete from freeze-thaw cycling, thereby helping minimize cracking, spalling, and frost heave.

In below-grade and under-slab applications, rigid foam insulation reigns compared to other materials. Traditionally, specifications have called for extruded polystyrene (XPS) in these areas, but EPS can perform as well, while being less costly and offering more design flexibility.

Drip, dry, drip, dry

Moisture degrades a material’s ability to insulate. Below-grade insulation frequently contacts wetted soil, so the key is to select a material that does not retain moisture. How do XPS and EPS compare with regard to moisture retention?

EPS made in accordance with ASTM C578, Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation (which governs both EPS and XPS), has very low moisture retention—it does not waterlog.

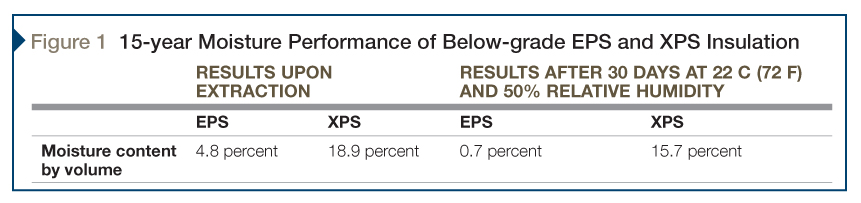

This means EPS releases moisture rapidly, quicker than XPS does. Over time, when soil is wetted and dried as the weather varies, EPS retains a lot less moisture than does XPS. A real-world evaluation by Stork Twin City Testing—an accredited independent testing laboratory—demonstrated this point. The lab examined sheets of EPS and XPS removed from a side-by-side installation after 15 years in service on a below-grade foundation in St. Paul, Minnesota. As summarized in Figure 1, the XPS was significantly wetter on extraction, with 18.9 percent moisture content by volume compared to 4.8 percent for the EPS. Further, after 30 days of ‘drying’ (to simulate practical temperature swings), the XPS still had elevated moisture of 15.7 percent, while the EPS had dried to 0.7 percent.

In cases where higher moisture shielding of foundations and slabs is crucial, EPS insulations are available with water-impervious facers and pre-cut drainage channels. (For more information, see “Specialty Insulations for Enhanced Moisture Protection”). These facers, which are factory-laminated to both sides of the EPS, make it almost impervious to moisture, and provide an enhanced level of moisture protection performance.

R-today, gone tomorrow

Beyond helping to keep water away from other building components, the degree to which exterior-applied insulations absorb moisture affects their R-value.

The aforementioned 15-year Minnesota in-situ testing also evaluated the R-value of EPS and XPS. The results showed the former retained 94 percent of its specified R-value, whereas XPS experienced a loss of almost half its R-value.3

In addition to the degrading effects of moisture on R-value, the aptly called ‘thermal drift’ of an insulator is another factor affecting insulating performance. EPS has long-term stable R-values, since it uses blowing agents that by design are already completely diffused at the time of manufacturing. In comparison, XPS uses blowing agents that diffuse from the foam’s cellular structure over the product’s life, thereby reducing its thermal performance with each day in the field. Thermal stability also gives EPS its ability to retain R-value through years of freeze-thaw cycling.

A simple way to check the long-term thermal performance of any insulation is to review the manufacturer’s warranty. Established EPS manufacturers typically warrant 100 percent of the published R-value for 20 years. By comparison, most XPS warranties typically cover only up to 90 percent of the published R-value in order to account for the degradation occuring in the field.

The International Energy Conservation Code (IECC) enumerates prescriptive R-value requirements for below-grade walls and slab-on-grade floors by climate zone. In the 2012 code, Table C402.2 (“Opaque Thermal Envelope Requirements”) has specific values, but it should be confirmed with the local building official.

When is strong too strong (or too expensive)?

A good below-grade insulation must be strong enough to withstand the pressure of the loads above it. For this reason, some EPS manufacturers provide a wide range of compressive strengths, from 69 to 414 kPa (10 to 60 psi)—this has made the material suitable for use as structural fill for highways and airport runways.

While the insulation strength is an important consideration, a common erroneous design assumption often leads to over-engineering for compressive resistance, which in turn adds unnecessary, and often very high, material costs. Over-engineering a building with 689 kPa (100 psi) below-grade insulation, when a 276 kPa (40 psi) board would have been adequate, can almost double the material cost.

Avoiding this error requires taking into account how the slab and sub-grade interact. Often, the assumption is made that concentrated loads applied to a slab (such as from a forklift or a vehicle) transfer directly to the sub-grade in a pyramidal prism shape. In reality, concrete slabs distribute loads evenly, which results in a lower compression strength needed for the insulation.

For example, a typical case might involve a 100-mm (4-in.) thick concrete slab under a forklift load of 3629 kg (8000 lb) applied via a tire footprint of 0.04 m2 (60 sq. in.). If one assumes the load transfers through the slab at a 45-degree angle, the tire’s force would be distributed over approximately 0.16 m2 (250 sq. in.) of insulation, for a force of 220 kPa (32 psi).

A more accurate calculation involves using a formula for the Theory of Plates on Elastic Foundations:

W = F / 8?(KD)

Where:

- W = slab deflection;

- F = load on slab;

- K = subgrade reaction modulus of insulation in lb/cu. in.;

- D = EH3 / 12(1?u2);

- E = modulus of elasticity of concrete in lb/sq. in.;

- h = thickness of concrete slab; and

- u = Poisson’s ratio for concrete (0.15).

The result of such a calculation for the previously stated scenario, and with a 50-mm (2-in.) thick layer of Type II EPS, for example, is a load on the insulation of only 17.2 kPa (2.5 psi)—well below the 58.6 kPa (8.5 psi) compression rating (at one percent deformation) of commonly available Type II EPS. Therefore, the EPS has plenty of strength for the applied load. As XPS is more expensive per inch than EPS, specification of a higher strength XPS would have unnecessarily increased the insulation costs.

Don’t be bugged

Sometimes concerns arise about rigid foam insulations used below grade providing a conduit for termites or carpenter ants to burrow through to reach the wood in a structure.

Following building code best practices in termite-risk regions can alleviate this concern. Local codes should be consulted for specific requirements. Additionally, some rigid foam insulations are available with non-toxic, inert additives that deter wood-damaging insects throughout the insulation’s service life.

Installing rigid foam insulation

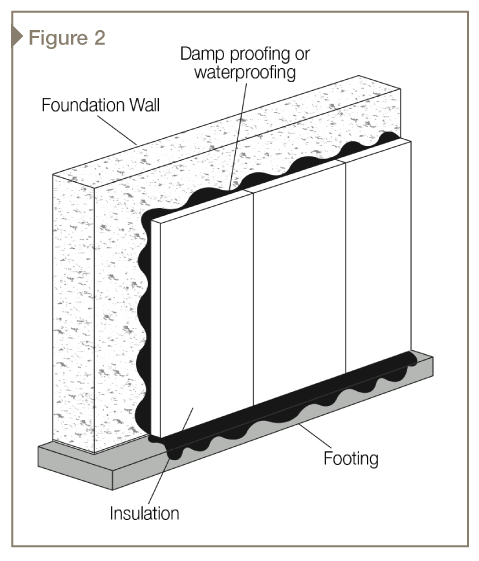

In below-grade applications, rigid foam insulation is applied over the dampproofing or waterproofing using a polystyrene-compatible adhesive or mechanical fasteners (Figure 2). Applying a bead of polystyrene-compatible caulk or mastic to the top of the insulation board minimizes water infiltration behind it. Additionally, the waterproofing or dampproofing must be properly cured before insulation is installed.

For under-slab insulation, the rigid foam is typically installed over a gravel base, with a poly vapor diffusion retarder between the gravel and insulation. Additional insulation is applied along the slab edges, as this is a primary surface for heat loss. To avoid damage to the insulation, it is necessary to ensure removal of any jagged surfaces or irregularities in the substrate before installing the rigid foam panels.

In both applications, it is important to confirm all details with the insulation manufacturer and local authority having jurisdiction (AHJ).

Bottom line

Expanded polystyrene offers similar or better performance characteristics as extruded polystyrene across key below-grade and under-slab insulation attributes: moisture retention, R-value stability, and compressive strength. While XPS provides a higher R-value per inch of thickness, EPS matches the performance at a much lower cost, thanks to the latter having the highest R-value per dollar among rigid insulations. Additionally, because EPS can be designed in various sizes and compressive strengths, it provides a greater degree of flexibility than does XPS. These factors are making EPS the go-to product for building professionals to help design the right below-grade insulation solutions at the right cost.

Many building projects throughout North America have used EPS successfully on foundation walls and beneath slabs. For example, the project engineers for a 2012 expansion to the Cold Climate Housing Research Center in Fairbanks, Alaska, specified 300 mm (12 in.) of EPS under a 150-mm (6-in.) floor slab. They were able to use a thicker, yet lower-compressive resistance product than they had initially planned, which improved the thermal performance, at a lower cost than originally budgeted.

In an example of a hot-region project, the concrete contractor for the Starwood Hotel Finance Headquarters in Scottsdale, Arizona, installed 6040 m2 (65,000 sf) of faced EPS panels under the floor slab.

Whether selecting EPS or XPS insulation, to ensure appropriate performance, it is critical to check that the specific product has been manufactured per ASTM C578, Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation.

Notes

1 See U.S. Department of Energy’s Office of Building Technology, “Slab Insulation Fact Sheet” at www.ornl.gov. (back to top)

2 See the EPS Industry Alliance’s “EPS Below Grade Series 103” Technical Bulletin at www.epsindustry.org. (back to top)

3 Ibid. (back to top)

Ram Mayilvahanan is the product marketing manager for Insulfoam, a division of Carlisle Construction Materials. He specializes in commercial building insulation. Mayilvahanan can be reached at ram.mayilvahanan@insulfoam.com.

To read the sidebar, click here.

A very well presented and clear presentation

What about the long term retained R-value, moisture retention, and PSI of urethane? I’ve seen “InstaPanels” that are faced with fiberglass which are promoted for underslab use, but they are made with yellow urethane foam.