To Vent or Not to Vent: Deciding what is best for attic applications

by Mason Knowles

For decades, designers of attics and crawl spaces have used cross-ventilation to minimize the potential for moisture accumulation and condensation. However, spurred by recent claims of energy savings and moisture control, unvented attics have become popular in both residential and commercial applications. While these attics can be used in many circumstances, this author believes there are reasons to use vented assemblies in many situations.

Traditional methods of insulation materials and design call for using air circulation within the attic space to assist in drying excess moisture. In heating and cooling climates, this moisture could potentially travel through fiber insulation in building cavities.

The traditional remedy to this wetting is to slow the influx of moisture-laden air into the cavity by using an interior vapor retarder, and by ventilating the roof cavity to the exterior in order to facilitate the carry off of moisture (i.e. drying).

When done correctly, attic venting can reduce the potential for condensation in winter and summer. During winter, the primary cause of attic moisture issues stem from warm moist air infiltrating into the attic space from the inhabited areas and condensing on cold surfaces. This can be intensified when lights, pipes, vents, and other penetrations pierce the attic floor. Too often, mechanical ventilation ducts from bathrooms, kitchens, or laundry rooms deposit warm, moist air into the attic instead of outside the building envelope.

When done correctly, attic venting can reduce the potential for condensation in winter and summer. During winter, the primary cause of attic moisture issues stem from warm moist air infiltrating into the attic space from the inhabited areas and condensing on cold surfaces. This can be intensified when lights, pipes, vents, and other penetrations pierce the attic floor. Too often, mechanical ventilation ducts from bathrooms, kitchens, or laundry rooms deposit warm, moist air into the attic instead of outside the building envelope.

A combination of air-sealing and insulating the attic floor while providing ventilation considerably reduces the potential for condensation, as warm moist air is less likely to enter the space and condense on cold surfaces. As a result, cooler, less humid air from outside can be drawn in from soffit vents placed on the roof’s lower portion, and flow through to rooftop or ridge vents, replacing warmer moist air that may have infiltrated into the attic.

In the summer, warm moist air mostly comes from outside the building. As such, it would seem venting the attic would increase the potential for condensation. However, the opposite is true if the attic floor is air-sealed and insulated.

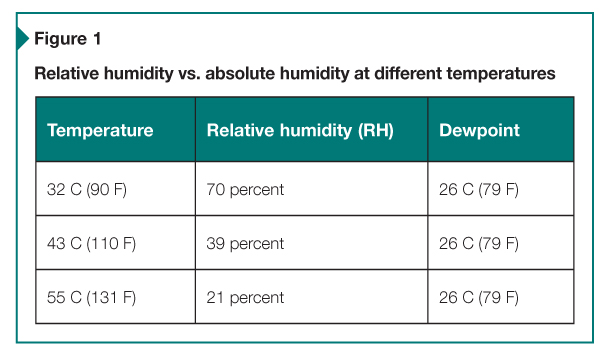

Even when outside air is hot and humid, if the attic space is air-sealed from the interior, it is much hotter than outside air. The hotter the air, the more moisture (i.e. absolute humidity) the air space can hold. Therefore, replacing the hotter attic air with cooler outside air—even at a considerably higher relative humidity (RH)—tends to dry the space, minimizing the potential for condensation.

As Figure 1 demonstrates, if the outside air is 32 C (90 F) and 70 percent RH, it is drier than interior attic space which is 43 C (110 F) at 40 percent or higher RH.

This design is less efficient when HVAC equipment and ductwork is in the attic space. In these instances, systems have a harder time maintaining the desired temperature. Air within ducts has a difficult time maintaining temperature when the space is overly hot or cold and must extend for long runs. In moderate climates, this does not pose a significant issue. However, in more extreme environments, both hot and cold, it can be a problem.

For example, depending on roof color and orientation to the sun, attic air temperatures can exceed 55 C (131 F) when it is less than 38 C (100 F) outside. This hot interior can make the ducts and HVAC equipment work much harder to reduce the temperature to comfortable levels. This is more pronounced if the ducts are leaky and HVAC equipment is drawing air from the attic space itself. Also, if the exterior surfaces of the HVAC equipment or ductwork reaches 26 C (79 F), it only requires 21 percent RH to cause condensation.

Unvented attic assemblies

Unvented attics rely on an air-impermeable insulation installed to the roof deck’s underside (i.e. attic ceiling) to stop airborne moisture from reaching a cold surface and condensing inside the building envelope. In this design, insulation effectively separates the interior and exterior spaces while slowing down moisture flow so the dewpoint is not achieved within the building envelope.

The two products most often used in an unvented attic assembly are medium- and low-density sprayed polyurethane foam (SPF).

In typical construction and climates, building code tables can be followed when using SPF as an insulation and air seal. However, in cases where a vapor drive is consistently moving in one direction—such as cold storage applications or swimming pools—it is prudent to conduct hygrothermal modeling or calculations to determine if the proposed design is right for the application.

Medium-density

Moisture calculations of building assemblies (i.e. hygrothermal modeling) and field observations demonstrate medium-density (i.e. 2-pcf) SPF eliminates potential for condensation in most climate zones and situations without venting or additional vapor retarder elements.

As per ASTM E96, Standard Test Methods for Water Vapor Transmission of Materials, medium-density SPF has a perm rating of approximately 1.5 to 3.0 per 25 mm (1 in.) and an R-value of about 1.05 per 25 mm (6.0 per 1 in.). It has also been tested to perform as an air-impermeable insulation.1 This combination of low permeance, high R-value per inch, and air barrier characteristics effectively slows vapor flow, separates the exterior environment from the interior, and eliminates introduction of moisture-laden air.

The physical properties and performance characteristics of SPF allow for the design of unvented attics and crawl spaces with minimal potential for condensation within.

Low-density

Hygrothermal modeling of building assemblies and field observations demonstrate low-density SPF can be used in warm and mixed climates without an additional vapor retarder element. However, in colder climates, an additional vapor retarder element is required to prevent the potential for condensation.

Low-density SPF has a permeance rating of between 8 to 15 per 76.2 to 127 mm (3 to 5 in.) and an R-value of approximately 0.616 per 25 mm (3.5 per 1 in.). When tested as part of an assembly, low-density SPF can be an effective air barrier.

The result is the physical properties of low-density SPF effectively separate inside and outside temperatures and minimize air infiltration, but allow a higher rate of water vapor transmission than medium-density SPF. This facilitates the design of unvented attics in warm and mixed climates without an additional vapor retarder, but requires an additional vapor retarder element in colder regions.

Either of these systems comes with a premium cost—typically two to three times the price of a blown fiberglass or cellulose vented attic assembly.

Combination attic assemblies

Modern residential design consists of elevations that can create various attic spaces within the same building. For example, this author’s home has attic space accessible with a standard door on the second floor and an upper section that can be reached only via a ceiling hatch. Dormers are also attached, making it extremely difficult to insulate as an unvented assembly. Additionally, some of the attic space is over an outside deck while other sections are over the house’s interior space. Furnaces, ducts, and air-conditioning (AC) equipment run throughout the attic spaces on all levels, except the dormers and the space over the outside deck.

When determining how to insulate this attic space, various assemblies were taken into consideration and a hybrid combination of vented and unvented attic space was planned.

The dormers and the attic space over the outside porch were sealed off from the rest of the attic by making a wall of plywood, then insulating the wall with closed-cell SPF. Following this, closed-cell SPF was also installed to the underside of the roof deck.

Building codes and attic assemblies

Since 2004, International Code Council (ICC) supplements to the International Residential Code (IRC) mean unvented attic assemblies have been accepted by the building codes in residential, but not commercial, applications. IBC requires ventilation in attics and crawl spaces and does not address the unvented attic concept. However, many building code officials have accepted unvented attics on a case-by-case basis when presented with compelling evidence —such as hygrothermal modeling of proposed assemblies—that the assembly will function properly. The requirements have changed slightly over the years, but many of the elements have remained the same.

The 2007 ICC supplement, International Energy Conservation Code (IECC) 202, “General Definitions,” introduced three new classes of vapor retarders:

The 2007 ICC supplement, International Energy Conservation Code (IECC) 202, “General Definitions,” introduced three new classes of vapor retarders:

- Class I: 0.1 perms or less;

- Class II: 0.1 to 1 perm;

- Class III: 1.0 to 10 perms.

Medium-density SPF at 51 to 76 mm (2 to 3 in.) thickness typically falls into the Class II category, while low-density SPF at 89 to 140 mm (3.5 to 5.5 in.) thickness falls into the Class III category.

The vapor retarder classes are important to correctly specify unvented attic assemblies. The qualifications for unvented attics are listed in IRC Section R806.4, “Unvented Attic Assemblies.” It requires the following conditions be met:

- it is completely contained within the building thermal envelope;

- no interior vapor retarders are installed on its ceiling side (i.e. attic floor);

- at least 6.3 mm (1/4 in.) of vented air space separates any wood shingles or shakes and the roofing underlayment above the structural sheathing; and

- for IECC’s Climate Zones 5, 6, 7, and 8, air-impermeable insulation is a vapor retarder, or a vapor retarder is installed in direct contact with the insulation (this would apply to low-density SPF).

Depending on the air impermeability of the insulation directly under the structural roof sheathing, the IRC section also requires one of these conditions:

- air-impermeable insulation only (i.e. closed cell SPF) must be applied in direct contact with the underside of the structural roof sheathing;

- in addition to the air-permeable insulation installed directly below the structural sheathing, impermeable rigid board or sheet insulation must be installed directly above the structural roof sheathing as specified in Table 8 (Figure 2) for condensation control; or

- air-impermeable insulation must be installed to the underside of the roof sheathing as specified in Table R806.4 for condensation control, while the air-permeable insulation must be installed directly to the underside of the air-impermeable insulation.

(This section would apply to flash and batt systems where a layer of closed-cell SPF is installed to the underside of the roof deck and another insulation such as fiberglass is installed directly to the SPF.)

Issues with unvented attics

Acceptance of the unvented attics and crawl spaces concept has generated some worry from those unfamiliar with the physical properties and moisture-control capabilities of SPF. A common concern heard when specifying SPF in these spaces is closed-cell foam installed to the underside of wood roof decks will lead to rotting because leaks go undetected due to the polyurethane’s water resistance. However, closed-cell foam repels liquid water. It seals cracks and crevices in the wood deck so any water getting past the roofing system stays atop the wood deck. Gravity then takes it down to the building’s edge and off the roof.

If the exterior surface of wood is wet when the foam is installed, then drying would occur from the roof-side to the exterior, not through the wood to the foam. This would be the same if the foam was not in place. If the wood is saturated, industry best practice calls for not installing the foam. If foam is installed to wet wood, it is apparent to the applicator and there would be open cells and lower density, allowing absorption of water into the foam. In this case, leaks would show up on the interior. Regardless, a roofing system should be regularly inspected to detect evidence of roof leaks and potential roof-deck damage. Foam insulation does not make damages more difficult to detect.

In colder climates, SPF can reduce the potential for ice damming. It prevents warm air from reaching the underside of the roof where it could melt snow, causing water to flow down and refreeze into the eaves. It is important to extend the insulation beyond the interior stud wall along the soffit space. If the air gaps are not sealed at the top of the wall, warm air can heat the underside of the roof deck and potentially cause ice dams in cold climates.

![Traditional vented attic assembly with both batt and blown-in insulation. [CREDIT] Photo courtesy CertainTeed](http://www.constructionspecifier.com/wp-content/uploads/2014/05/Cti09PapRbwTc0002C-1000x671.jpg)

![Attics with small and unusual configurations might also benefit using unvented assemblies. [CREDIT] Photo courtesy Mason Knowles Consulting LLC](http://www.constructionspecifier.com/wp-content/uploads/2014/05/Carolina-Foam-087-1000x750.jpg)

Some asphalt shingle manufacturers specifically exclude warranties based on “inadequate attic ventilation.” However, others allow use of SPF installed to the underside of roof decks in unvented attics in their warranties.

Engineering studies conducted by Carl Cash (former chair of ASTM D08 Committee on Roofing) explored the premise of attic ventilation and its effect on shingle temperature compared to other factors that could influence shingle temperatures. According to Cash:

Venting the roof deck reduces the average temperature of the roof –1.75 C (5 F), which is one-third the influence of the color of the shingles, the aspect of the roof (direction it faces) and 1/36 the influence of geographic location.

Another oft-cited concern is since closed-cell spray foam is a vapor retarder, it cannot be used in warm, humid climates as it prevents water vapor from going in and out of the assembly.

Closed-cell spray foam has a perm rating of approximately 1.5 to 3.0 per 25 mm (1 in.) and an R-value of approximately 1.05 per 25 mm (6.0 per 1 in.) This combination allows a controlled moisture vapor flow, while separating the inside and outside environments. The result is better control of condensation within the building envelope so long as there is sufficient SPF insulation to prevent condensation. In most applications, 12.7 to 25 mm (0.5 to 1 in.) of SPF will suffice in warm and mixed climates, and 38 to 63.5 mm (1.5 to 2.5 in.) is needed in colder regions. It should be noted hygrothermal modeling calculations are recommended when atypical conditions occur, such as extreme environments and unusual construction or design.

When using a hybrid insulation system, such as closed-cell sprayfoam covered with fiberglass or cellulose insulation, a greater thickness of closed-cell foam is needed to reduce the potential for condensation.

Another question on the use of sprayfoam is what happens when an applicator unintentionally sprays foam to wet lumber, particularly wet-framing members. Research has been conducted on installing SPF to wet lumber. Dr. Mark Bomber’s book, Spray Polyurethane Foam in External Envelopes of Buildings, reports on research conducted on the subject. This research demonstrates closed-cell foam under typical building conditions (i.e. when installed over wood framing that has 28 to 35 percent moisture content) took approximately 35 days to dry less than 19 percent moisture content compared to 8.5 days to dry with no foam attached. It also reported the air-sealing qualities of the foam were retained.

![This is a detailed diagram of air flow into and out of an attic. [CREDIT] Image courtesy CertainTeed](http://www.constructionspecifier.com/wp-content/uploads/2014/05/I-VentilationHouse_sm-1000x857.jpg)

Regardless, the SPF industry does not recommend spraying either open or closed-cell foam on wet or damp surfaces because the foam adhesion will be affected. Similar to painting and coating applications, substrates to receive SPF of all types should be relatively dry (e.g. wood at an 18 percent moisture content maximum). This can be easily checked with a moisture meter. Installers know instantly whether the wood surface is wet, because the liquid reacts with the moisture, causing a color variation and poor foam rise.

Conclusion

In conclusion, one size does not fit all when determining whether to use a vented or unvented attic assembly. Just because something is popular or trendy does not make it the best choice. Variables influencing the decision to vent or not vent include:

- interior and exterior temperature and humidity;

- type of HVAC and ductwork;

- anticipated vapor drive;

- construction materials;

- building type;

- configuration of the structure; and

- building codes.

It is important for a specifier to take all these factors into consideration before drawing up plans and making a final recommendation.

Notes

1 Materials that have been tested in accordance with ASTM 283 to allow less than 2 L/m2 of air at 75 kPa. (back to top)

Mason Knowles is president of Mason Knowles Consulting LLC, specializing in providing educational/training, troubleshooting problem applications, technical services and articles, and presentations specific for the spray foam industry. He has 42 years of experience in the spray foam industry as a contractor, sprayed polyurethane foam (SPF) and equipment manufacturer, and trade association executive. Knowles chairs the ASTM Subcommittee on Spray foam Roofing and the ASTM Task Group responsible for ASTM C 1029, Spray-applied Polyurethane Foam Specification. He is a Sprayed Polyurethane Foam Association (SPFA)-accredited building and roofing inspector and an instructor for SPFA courses for applicators and inspectors. Knowles is a member of the International Code Council (ICC), RCI International, Insulation Contractors Association of America (ICAA), SPFA, Building Enclosure Technology and Environment Council (BETEC) and Roofing Industry Committee on Weather Issues’ (RICOWI’s) Hurricane and Hail Investigation Teams. He can be contacted via e-mail at masonknowles@aol.com.

To read the first sidebar, click here.

To read the second sidebar, click here.