A paradigm shift in specifying temporary structures

by Beth Wilson

Clear-span aluminum structures and temporary steel buildings have advanced over the years. Knowing when to use them is a skill worth mastering for construction specifiers, procurement professionals, and facility managers. Familiarity with specific spaces, and knowing the assemblies’ framework of costs and benefits, may also help designers and specifiers incorporate them into their own sites and make optimal recommendations.

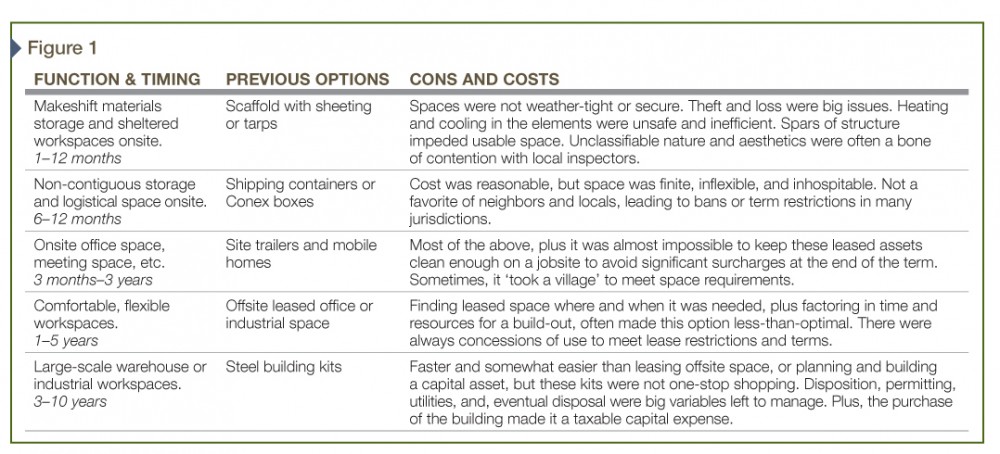

For those who have been in the trade for a while, there may be a natural aversion to temporary structures. Historically, these options have been expensive, constrictive, and almost universally required functional concessions on some level. Up until about a decade ago, if space was needed immediately or in the near-term for occupancy of less than five years, there were not a lot of reasonable options (Figure 1).

New options

Since the turn of the century, there have been exponential improvements in the strength, quality, versatility, cost-effectiveness, and energy efficiency of clear-span aluminum and temporary steel structures. The result has been a paradigm shift in the consideration of temporary space.

Although modular trailers have come a long way in form, function, and versatility, they are generally designed for office and classroom use and are not typically scalable without creating a village. When larger, contiguous, weather-tight warehouse or workspace is needed, the two best options are industrial clear-span tents and temporary steel buildings.

Clear-span structures

There are several classes of clear-span structures that can be installed onsite in less than one week, outfitted with utilities and a full range of access, safety, and security features. Also called ‘industrial tents,’ these aluminum systems include stretched fabric.

These are lightweight aluminum structures offering both durability and versatility. Typically, they are deployed for up to six months at a time in temperate climates where sun protection is more of a priority than severe weather, such as petrochemical facilities and oil fields in Texas and Louisiana. A structure rated for a wind speed of 144 kph (90 mph) is more than sufficient to protect contents and occupants from summer thunderstorms. Further, these structures can be relocated fairly easily, making them a good choice if site flexibility is an issue.

If a more substantial structure is needed in harsher climates for at least three months, an aluminum box beam system is a better option. These can withstand winds up to 209 kph (130 mph) and snow loads of up to 146 kg/m2 (30 lb/sf).

For hangar-type applications or environmental remediation sites in snow country, a peaked arch structure is the best option, as it is engineered with a slope for snow shedding. This is a light-weight structure, which can also be moved with ease.

Temporary steel buildings

Similar to clear-span aluminum systems, temporary steel buildings offer the key benefits of a permanent structure without the long ‘planning/building’ wait and long-term commitment to real estate. They are designed with the aggregate of state and local building codes in mind. Most, if not all, are compliant with American Society of Civil Engineers (ASCE) guidelines, International Building Code (IBC), and California Fire Marshall Code (equal to or exceeding the standard issued by the National Fire Protection Association [NFPA]). Given these considerations, obtaining permits and approvals is usually expedient. Also, because clear-span structures have no interior uprights to impede usable space, flexibility is maximized.

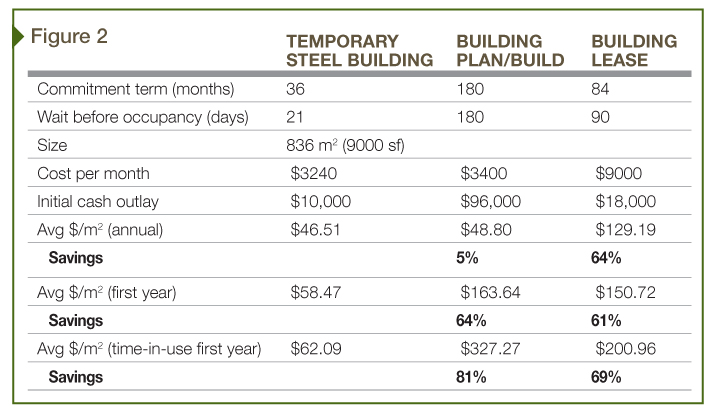

Perhaps most compelling in the consideration of temporary steel buildings is their low upfront and monthly cost over a three-year term when compared to plan/build and lease options. Particularly when one considers lease and plan/build expenses start well before the space is ready, it is worth noting the cost per square meter for time-in-use during the first year (Figure 2).

Time-framing the decision

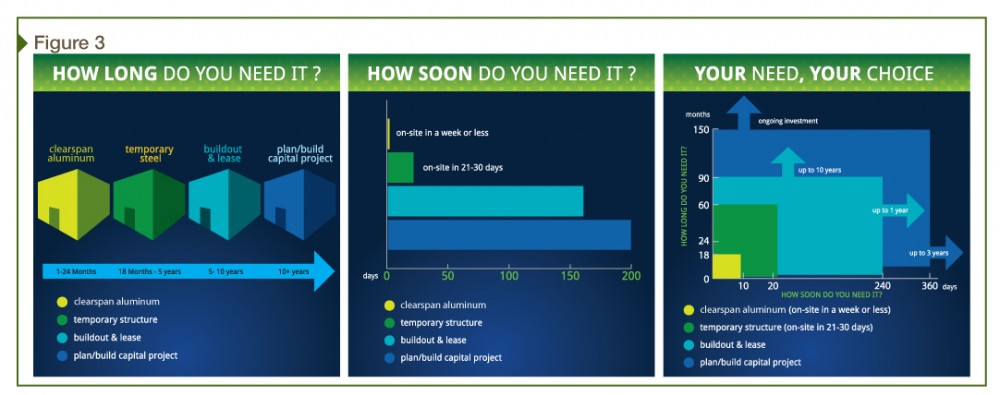

There are two primary questions that frame the ideal spot for using clear-span aluminum structures and temporary steel buildings: How soon is it needed, and for how long?

A clear-span aluminum structure can easily meet an immediate need and is typically durable enough to remain installed onsite for up to two years. Temporary steel buildings can also be onsite quickly—21 to 30 days in most cases—and serve a three- to five-year term. The structures can certainly last longer, but it becomes a less economical choice.

If the need is not immediate, and the term is more than five years, then leasing, purchasing, or building offsite space become better options (Figure 3).

While some larger organizations have entire departments dedicated to property planning, investment, and management, others choose to stay focused on core businesses and avoid the complexities of long-term real estate entanglements. The latter is an ideal scenario for temporary structures. Also, because temporary buildings are considered an operating expense as opposed to a capital expense, many organizations see tax benefits in their use. Additionally, the overall cost for space needed for five years or less can be as much as 81 percent less per square meter.

Finally, both aluminum and steel clear-span structures can generally be installed without a poured or pieced foundation. A dry, level lot, or a paved parking lot, are all that is needed for installation. This is a big factor on the shortened installation timeline, and also exempts temporary buildings from property taxes in most jurisdictions.

Energy efficiency, sustainability, and LEED

Previously, the term ‘temporary’ was used to infer flimsy and disposable. With advances in materials and engineering, temporary structures can be designed to be energy-efficient, and their elements are generally reusable and recyclable. A temporary building may not be certified under Leadership in Energy and Environmental Design (LEED) on its own, but employing one may help qualify a larger project for points. Suitable vendors should obtain materials from recycled sources, repurpose its structures (or elements thereof), and recycle materials at the end of their useful life. For example, a manufacturer targeting LEED accreditation could use a temporary structure to expand a production facility, as opposed to building a larger permanent facility.

Specifically, potential LEED credits include:

- Materials and Resources (MR) 1.1, Building Reuse–Maintain Existing Walls, Floors, and Roof;

- MR 1.2, Building Reuse–Maintain 50% of Interior Non-structural Element;

- MR 2, Construction Waste Management—if a vendor can prove elements of a structure will be recycled at the end-of-life; and

- MR 3, Materials Reuse—if the structure used has been erected before.

In addition to LEED benefits, many vendors now offer energy-efficient lighting and HVAC options, as well as insulated wall panels ranging in R-value from R-13 to R-30. These buildings are often used for safety and craft ‘tents’ in the harshest of summer and winter climates, offering refuge for workers on remote sites. The cost of utilities in operating these is greatly reduced from the tents of a decade ago.

Utility and safety are essential

The U.S. Army Corps of Engineers (USACE) frequently makes use of clear-span structures and temporary steel buildings in disaster relief and recovery efforts, as well as for environmental remediation. The requirements for these projects are frequently as rigorous as a permanent structure, including wind and weather, energy efficiency, utilities, security systems, and custom interior finishes. Sometimes the only difference is the timeframe—onsite immediately, or in less than a month.

The safety and professional certifications of a chosen vendor should be considered when choosing a temporary structure for a site. Often sites have specific requirements, such as:

- Transportation Workers Identification Credential (TWIC);

- Defense Information Systems Agency (DISA);

- Occupational Safety and Health Administration (OSHA); and

- National Center for Safety Initiatives (NCSI).

On May 22, 2011, an Enhanced Fujita (EF) 5 tornado hit the town of Joplin, Missouri. Public infrastructure was leveled, including an elementary school with a large multi-purpose room (i.e. the cafeteria, gym, and auditorium) that also served the larger community for meetings and events. Replacing such a core asset for the town became a priority for the USACE team, and so a fully functioning gymnasium for the elementary school was installed. The 20 x 30-m (66 x 100-ft) community-uniting facility was bigger and stronger than the multipurpose room that stood before the storm. The steel I-beam construction with vertical steel sidewalls and pre-stressed roofing material provided a solid structure around which the community could rebuild itself.

Bringing a building to you

In late 2011, integrated energy company Entergy, was up against a federal deadline to update the nuclear cores at Grand Gulf Nuclear Power Station in Port Gibson, Mississippi. The cost of moving the reactor units to a controlled work environment would have been astronomical.

A custom structure was built over the reactors in place. In less than three weeks, a 25 x 40-m (82 x 132-ft) building was erected. A portion of the building had 6.4-m (21-ft) uprights to accommodate the use of heavy equipment inside, while the balance had 4.8-m (16-ft) sidewalls. The two were merged around an existing security fence and plantings, avoiding the need to alter the site, which would have required a lengthy and involved permitting process.

Two additional structures were also used. One tent was used for meals and safety meetings for the project laborers and a second was created to shelter the nuclear waste disposal process. When the old cores were replaced with the new more efficient ones, an aluminum temporary structure provided a controlled environment for the load-out from the tanks.

The plant was shut down during the changeover, making time of the essence. This was an ideal application of temporary structures, which provided the required workspaces on-demand, while minimizing logistics and expenses.

Interim solutions

For most of the 20th century, the fire station at the Port of Los Angeles was a unique landmark—a towering covered boathouse that protected the expensive vessels and equipment the crews used to fight fires in the port. In 1986, the boathouse was demolished, making way for the development of a new cargo container complex.

The Ralph J. Scott, a 30-m (100-ft) fireboat commissioned in 1926, was then moved to an open water slip in the port. In 1989, it was declared a National Historic Landmark, but, left to the weather, the elements took their toll. Fireboat #2, as it was also called, was retired in 2003. The weather contributed to the deterioration, and there were few laborers left with the skills to maintain the hand-riveted hull. The fireboat sat on a cradle behind the award-winning Station 112 in the Port for many years awaiting a visitor-friendly facility and the funding and manpower for the restoration. An interim shelter to prevent the vessel’s further deterioration was needed, as well as an enclosure where the restoration of the Los Angeles Fire Department’s (LAFD’s) longest-serving apparatus might commence.

In early 2013, a plan was delivered to the Port and the onsite building erection was completed in a total of 21 days. The Ralph J. Scott now sits in a custom building at the Port of Los Angeles—a 15 x 36-m (50 x 120-ft) structure with custom 10.67-m (35-ft) sidewalls and a 32-degree roof pitch. Special eave and gable framing support the taller sidewalls while maintaining a clear-span working space in the center to accommodate the ship’s shape.

Conclusion

From school gymnasiums to nuclear reactors to historic sites, temporary buildings offer a range of flexible, durable, and safe options that are both cost-effective over the short term and energy-efficient in the harshest of climates. While planning future projects, it is critical to ask the ‘how-soon’ and ‘how-long’ qualifying questions to determine whether a clear-span aluminum structure or temporary steel building should be considered.

Beth Wilson is the marketing manager for Mahaffey Fabric Structures—a vendor for the U.S. Army Corps of Engineers (USACE), Exxon, S&B Engineers and Constructors, the U.S. Army, and Turner Construction. She is a board member for the Memphis Regional Chapter of the U.S. Green Building Council (USGBC) and has been published in more than 20 industry publications. Wilson was instrumental in promoting Mahaffey’s sustainable Boomerang Building product line and providing guidance on building components made from recycled material with the goal of achieving LEED points. She is also an accomplished presenter and mentor for those seeking CMP credit with the USGBC and the Green Building Certification Institute (GBCI). Wilson can be contacted by e-mail at beth@boomerangbuildings.com.