A guide to field notching and drilling LVL and glulam

Laminated veneer lumber

Most LVL products are used as beams and headers loaded parallel to the gluelines. Drilling, tapering, or notching of LVL reduces the net section and may introduce stress concentrations at the notching or drilling location. Therefore, a cautious approach to field modifications is vital. Note, LVL is a proprietary product and the notching and drilling requirements specified by the LVL manufacturer must be followed and supersede the general recommendations provided hereinafter.

Notching

Notching of LVL beams should be avoided whenever possible, especially on the tension side of a member. Tension-side notching of LVL beams is not recommended except at end bearings, and then only under specific conditions. The notching of LVL beams on the tension side results in decreased strength caused by stress concentrations developing around the notch and a reduction of the net cross-section resisting the bending and shear forces. Such notches induce perpendicular-to-grain tensile stresses, which, in conjunction with horizontal shear forces, can cause splitting along the grain, typically starting at the inside corner of the notch. Stress concentrations due to notches can be reduced by using a gradually tapered notch configuration in lieu of a square-cornered notch. Rounding the square corner of a notch with a radius of approximately 13 mm is also recommended to reduce stress concentrations in these areas.

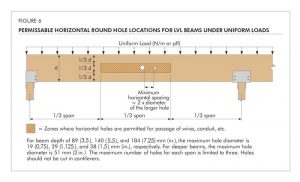

LVL beams illustrated in Figure 6 are assumed to be simple span subjected to uniform loads. All equations and notching guidelines are presented using the same assumptions. If this information is applied to continuous or cantilevered beams, it should be used with extreme caution and only based on rational engineering analyses.

Where LVL beams are notched at the ends for bearing over a support, the notch depth is recommended to not exceed one-tenth of the beam depth (Figure 6[e], on page 16). Within the limitation given above, the shear stress at the notch can be calculated in accordance with Figure 6(e). For notches on the compression side, a less severe condition exists and equations for the analysis of the effects of these notches are also given in Figure 6 (on page 16). The equations given are empirical in nature and were developed for the conditions shown.

The notching provisions are limited to uniformly loaded simple-span beams. The notches shown in Figure 6 occur in areas of high shear and lower moment. For this reason, the design equations given are shear equations.

When necessary to cut a small notch in the top of an LVL beam (in the compression side) to provide passage for a small-diameter pipe or conduit, the cut should be made in an area of the beam stressed to less than 50 percent of the allowable bending stress. The net section in this area of the beam should be checked for shear and bending stresses to ensure adequate performance.

All field notches should be accurately cut. It is important to understand improperly cut field notches may reduce the capacity of a beam and cause serious structural failure. Avoid over-cutting at the corners of the notch. Drilling a pilot hole in a member at the interior corner of a notch as a stop point for the saw blade provides both a rounded corner and minimizes over-cutting at the corner.

It should be recognized the top of an LVL beam might not always be stressed in compression and the bottom of an LVL beam might not always be stressed in tension. For example, if the LVL beam is designed for wind uplift, the top of the LVL will be stressed in tension and the bottom of the LVL will be stressed in compression. In this case, the recommendations given above should be applied accordingly. Further, when evaluating the effect of notching, the shear force within a distance from supports equal to the beam depth should not be neglected, as typically permitted by the design of rectangular wood members in accordance with the National Design Specification for Wood Construction (NDS) in the U.S. and the Wood Design Manual in Canada.

Horizontal holes

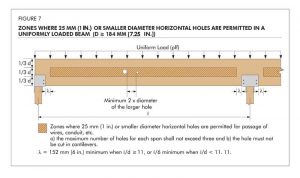

Like notches, holes in an LVL beam reduce the net section of the beam at the hole location and introduce stress concentrations. This causes a reduction in the beam capacity. For this reason, horizontal holes in LVL are limited in size and location to maintain the structural integrity of the beam. Figure 7 shows the zones of a uniformly loaded beam in simple or multiple spans, where the field drilling of holes may be considered. The requirements given consider the effect of the horizontal hole on the shear and moment capacities of an LVL beam and may be applied to multiple-piece built-up LVL beams.

APA Technical Note, Effect of Large Diameter Horizontal Holes on the Bending and Shear Properties of Laminated Veneer Lumber, Form V900, provides additional engineering guidelines where larger horizontal holes than those specified here cannot be avoided in design.

A 25-mm diameter or smaller hole may be cut at the middle third of the beam depth anywhere along the span, except for the area within 152 mm of clear distance between the face of the support and the nearest edge of the hole (Figure 8), provided the following conditions are all met:

• the beam is at least 184 mm in depth;

• the beam is subject to uniform loads only;

• the span-to-depth ratio is at least 11;

• the maximum number of holes for each span is limited to three;

• the horizontal spacing must be a minimum of two diameters clear distance between adjacent holes based on the diameter of the larger hole; and

• the hole must not be cut in cantilevers.

If l/d of the beam is less than 11, a 25-mm diameter or smaller hole may be cut in accordance with the provisions listed above except the location of the hole must maintain a clear distance between the face of the support and the nearest edge of the hole of at least one-sixth of the span (Figure 9, page 20).

Field-drilled horizontal holes should be employed for access only and should not be used as attachment points for brackets or other loadbearing hardware unless specifically designed as such by an engineer or designer. Examples of access holes include those used for the passage of wires, electrical conduit, small-diameter sprinkler pipes, fiber-optic cables, and other small, lightweight materials. For oversized LVL beams, the guidelines given above may be relaxed based on an engineering analysis. When holes are required to be drilled outside the allowable zones, an engineering analysis should be conducted and approved by an engineer or architect qualified in wood design.

Regardless of the location, holes drilled horizontally through a member should be positioned and sized with the understanding the beam will deflect (creep) more over a period of time under in-service loading conditions. This deflection could overstress supported equipment or piping unless properly considered.