by Ron Utzler

Within the built environment there are many avenues to energy savings. The energy efficiency of a building is affected by everything from lighting and windows, to insulation and reflective roofing. This article focuses on low-slope roofing materials that represent reflective roofing options.

Reflective roofing is typically a method of using light-colored surfacing that reflects more of the sun’s heat than it absorbs. A reflective value is the portion of light reflected, measured from 0 to 1, with higher values representing cooler surfaces. These values are measured with sophisticated, calibrated equipment under controlled conditions.

Providing roofs with a reflective surface is not a new concept. For example, asphalt coatings with leafing aluminum pigment have always promoted the benefit of reducing interior temperatures while slowing the oxidation of the waterproofing membrane. This reduces the load of air-conditioning systems and improves the occupant’s comfort, while extending the service life of the roof membrane.

However, the term ‘cool roofing’ was more recently coined with the increased focus on the reduction of energy consumption. As with any movement, there are opportunities for entrepreneurs to provide support and related services. Everything from third-party testing laboratories to new programs for certification have been evolving.

There are federal agencies, for example, that have decided all roofing in certain regions must meet Energy Star’s cool roofing requirements. The U.S. Environmental Protection Agency (EPA) established the voluntary Energy Star program which requires a roofing membrane to have an initial reflectance of .65 and a three-year-aged reflectance of .50 to be considered Energy Star rated. So, design teams should consider available roofing options in compliance with cool roofing requirements.

Cool roof systems are beneficial in climates where a building’s interior requires more cooling days, as opposed to heating days. Whether the goal is to reduce energy cost or improve the environment, building owners and specifiers must make educated decisions about roofing needs. To still have a cool roof, they need to be familiar with the available options, along with advantages, disadvantages, and cautions. This article contains a general overview of the low-slope roof system categories that can be installed with at least the initial reflectance to be considered a cool roof.

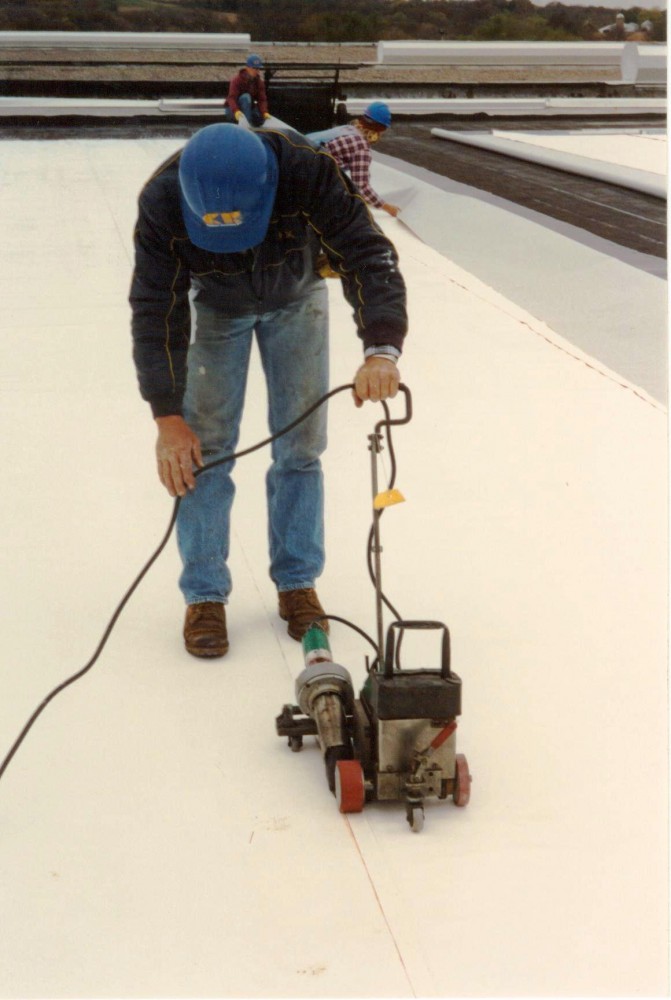

Single-ply membrane systems

As the name indicates, single-ply membrane assemblies are synthetic sheets in various combinations of compounds with or without reinforcement options, and installed in a single layer held in place by mechanical fasteners, adhesives, or some form of ballast. Most, if not all, of these membranes are available in white, and will provide the reflectance required to be considered a cool roof. Naturally, to take advantage of this reflectance, the membrane will either be adhered or mechanically fastened. A ballasted system may still qualify as a cool roof, depending on the color of the ballast itself.

Advantages of this assembly include:

- application of one membrane will generally result in lower material and labor cost;

- these membranes are typically available in bright white and their smooth surface provide the highest level of reflectance;

- non-ballasted applications result in a smooth surface generally easier to visibly locate leak sources caused by defects or damage; and

- in many cases, these membranes are manufactured with a gloss finish or clear film to provide a surface that resists dirt pickup, providing a self-cleaning attribute that can help maintain higher reflectance over time.

A disadvantage of this roof type is a single layer of waterproofing is more vulnerable to physical damage, resulting in wet insulation and interior leaks, depending on the deck type. For example, a structural concrete deck can hold more water in the system above the deck before it builds up to a break in the deck, allowing water to leak into the building. Unfortunately, this can cause more insulation damage from a single puncture because the leaks may go undetected until water enters the building’s interior. Of course, this concern for an unknown leak is based on the deck type and therefore applies to all systems, once the membrane’s waterproof integrity is broken.

Additionally, the anticipated useful life of a single-ply membrane is generally considered less than multiple-ply assemblies. This is most often viewed as an attribute of the mass (thickness) of the waterproofing membrane, which decreases over time by oxidation.

The amount of traffic on the membrane surface will also add a wear factor. Strategically placed walk treads helps can help.

When specifying these systems, it is important to keep in mind the membranes can be extremely slippery when wet. Further, because they are white means rainwater, dew, frost, and snow will be slower to evaporate. If someone is required to spend any length of time on a white membrane on a sunny day, wearing sunglasses is important.

Design teams should also be aware some membranes may have a short history of service in their current formulation. If a formula is changed to address a newly discovered performance issue, the alteration could produce a completely different, unanticipated problem after real exposure.

The local conditions of a particular roof exposure must also be considered. For example, if the roof will be exposed to chemical fallout from a manufacturing process, the chemical content and concentrations involved must be determined, so a membrane with the best resistance to those exposures is specified. The membrane supplier should be able to provide a chemical resistance chart for its product.

Modified bitumen membrane systems

The modified-bitumen (mod-bit) membrane systems include sheet membranes made with asphalt typically modified with rubber or plastic compounds and reinforced with either glass or polyester mats. Typically, the surface ply is manufactured with light-colored mineral granules embedded.

Historically, these granules typically provided an initial reflectance value of .25 to .27 on a scale of 0 to 1. However, as the drive for energy savings grew, manufacturers developed brighter granules, or other methods to increase the product’s reflectivity. Some of these methods include the embedment of other synthetic white chips, rather than granules, or factory-coating the sheet with a brighter white coating.These brighter versions have raised the reflectance values to .70 to .80.

Such systems emerged in the United States in the 1980s after years of use in Europe, and have grown in popularity. Originally, the asphalt-based systems seemed a natural progression for contractors who were used to installing hot-applied built-up roofing (BUR) systems. They have reached a level of development where they are dependable membranes that also provide redundancy of plies.

Advantages of the mod-bit membrane systems are that they are typically installed in hot asphalt, cold-applied adhesive, heat welding or self-adhered, providing various options for the project’s needs. For example, getting hot asphalt to the top of a high-rise building may not be practical, but pails of cold-applied adhesive can be delivered to the roof. Also, maintenance and minor repairs can generally be completed with readily available asphalt materials.

An important attribute to the surface’s performance, the granulated membrane refers to the quality of the granule embedment. This is a key standard of quality that will determine how long the membrane weathers and wears before the mineral granules are dislodged and accumulate in the gutters and drain sumps. Referring to ASTM D4977/6164, Standard Test Method for Granule Adhesion to Mineral-surfaced Roofing by Abrasion, granule loss should not be greater than 2 grams. This value is not always reported in manufacturer’s product data sheets, but it is still an important feature to compare during the membrane selection process.

The consistency in granule color is not always able to be maintained by manufacturers. Slight variations from one production lot to another can show up on the same roof, leading to an inconsistent appearance in a finished project.

Since these systems are typically adhered with asphalt adhesives, it depends on the applicator’s expertise to avoid the unsightly appearance due to tracking the adhesive onto the finished surface, or uncontrolled bleed-out of adhesive at membrane laps. While the embedding of extra granules in the bleed out during application and applying white coating to tracked adhesive is often effective in providing a good finished appearance, this author is a proponent of post-coating the completed installation.

Due to the inconsistent shades of white previously mentioned and application aesthetics, the added initial cost to the project for the application of a quality acrylic elastomeric coating system can provide both immediate, and long-term benefits. It gives the immediate benefit of uniform appearance and maximum reflectivity, with the long-term advantage of an extended service life of the membrane. Even if the owner elects not to periodically recoat the surface, the initial coating can provide an additional five or more years of service as a sacrificial surfacing in the roof’s lifecycle.

The wide variety of membrane reinforcements and coating compounds means determining the right membrane for the given conditions will need to be an important aspect of the specification process. Design teams should factor in the anticipated amount of foot traffic on the roof system and include walk treads as a design element.

Built-up roof systems

As the name implies, built-up roofing (BUR) systems are assembled on the roof using multiple plies of reinforcement built-up with bitumen interply adhesives. Traditionally, BUR systems are surfaced with a flood coat of bitumen into which gravel is imbedded. While BUR is the oldest system, with a history long-term performance, it has fallen into disfavor with the rise in popularity of reflective cool roof systems. However, there are bright white gravels available for surfacing enabling the traditional BUR to qualify for cool roof status.

There has also been a rise in popularity in what is referred to as a ‘hybrid’ system. This combines the redundancy of reinforcement plies of BUR with the white granule surfacing of a mod-bit cap sheet. Traditional BUR with gravel provides a time-proven, durable system with a long lifecycle. Further, the gravel surface and number of plies provide traffic and puncture resistance.

Some disadvantages to these systems can include objection to the odor of hot bitumen at the project site and the ensuing potential complaints from the building occupants. However, there are fume-recovery equipment options, and there are cold-applied adhesive systems available.

In some high wind regions, gravel roofs may be resisted due to potential of gravel becoming projectiles. While this is a real concern for single-ply ballasted (i.e. loose-laid) roofs, the smaller gravel used to surface BUR roofs is typically adhered.

BUR roofs with gravel will generally weigh more than other membrane types, so the decks should be verified as capable of bearing the weight. If using hot asphalt or even cold adhesives, the surroundings and building occupancy should be taken into account and require a fume recovery or afterburner kettles for hot asphalt. Additionally, air intake vents should be covered during application.

SPF systems

Sprayed-in-place polyurethane foam (SPF) systems combine two chemical components—isocyanate and resin—through specialized spray equipment. As the resulting liquid is applied to a substrate, it will expand 20 to 30 times its volume to form insulating polyurethane foam. The foam is generally applied in multiple passes of the spray gun resulting in layering 12.7 to 38 mm (½ to 1 ½ in.) per pass (or ‘lift’). A good applicator can control the lifts and construct a uniform taper to drains for proper water drainage.

Applications of SPF need to be surfaced to protect it from ultraviolet (UV) degradation, and to provide waterproofing, along with protection from physical damage and fire resistance.

The most typical surfacing is white elastomeric coating. A foam application is considered monolithic, as opposed to individual rigid insulation boards. This would reduce stress on the waterproofing membrane which could occur at the joints of rigid insulation.

Sprayfoam applications are considered self-flashing since each pass can be completed with a continuous movement from horizontal to vertical substrate. This reduces the chances of detailing errors in critical areas of stress.

The expertise of the applicator is crucial to the success of SPF systems. For example, if the component mixing is off ratio, the resulting foam would have different performance properties pertaining to rigidity or softness. Weather conditions during application are also crucial because of the way these products react to moisture. This can affect the foam’s surface texture, making effective coating application more difficult.

Conclusion

As demonstrated here, there are numerous roof systems that can qualify for cool roof ratings. The building owner’s individual needs and conditions will affect how the best system is selected.

It is important to keep in mind that no matter which roof system is selected; it will not perform as expected unless there is a proper evaluation of needs versus options, along with the appropriate budget. Additionally, detailed specifications with project-specific predesigned details need to be included. Finally, the installation should be contracted to a qualified applicator having experience with the specified system.

Ron Utzler has been involved in the technical aspects of commercial roofing systems for 35 years. He is currently technical director at Viridian Systems in Tallmadge, Ohio. Utzler can be reached by email at ronutzler@live.com.

Latest technology has given the gift of cool roof. Which have the advantages of saving your property and roof in present and future? Applying Liquid Roof RV has made it possible to save your roof for twenty years even. I really like it very much.