A systemic approach to waterproofing foundations

by sadia_badhon | May 7, 2020 10:37 am

by Peter Barrett

[1]

[1]The major cause of foundation-related problems is water. Hence waterproofing systems are very critical to keeping foundations dry. Like air control above grade, it is important to consider water control below grade as a system solution, and not just as a single component.

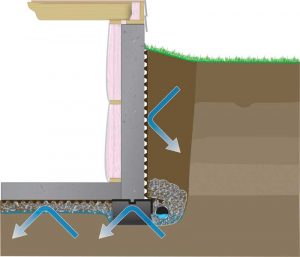

A properly installed and performing waterproofing membrane is important, but without an adequate drainage system to allow the liquid to flow away, water can damage any construction project. An improperly conceived waterproofing system can allow the buildup of hydrostatic pressure, turning cracks in the foundation into entry points for water.

When water enters the building interior, there is not only a risk of unsightly water damage, such as rust-colored stains or spots, but also uncontrolled moisture introduces humidity, thereby creating a very desirable home for mold and mildew. The unwelcomed water will also damage building materials.

To properly protect a concrete foundation, the wall must be shielded against the water and the liquid must be directed away from it. Selecting an appropriate below-grade solution for commercial buildings is one of the most important aspects of maintaining structural integrity, indoor air quality (IAQ), and comfortable living or working conditions for all the occupants. To make the right decision, it is wise to first understand site conditions and the science behind movement of moisture from concrete footings up the wall.

[2]

[2]Understanding site conditions

In accordance with section 1805.3.2, “Walls,” of the 2018 International Building Code (IBC), concrete or masonry walls retaining earth and enclosing interior spaces and floors below grade shall be waterproofed—designed and constructed to withstand hydrostatic pressures and other lateral loads. When selecting a waterproofing system, it is important to understand the overall water management system goals for site conditions. Soil quality, water table location, and how the system will be installed are all important considerations.

Different soils drain differently. Some hold tonnes of water, and others will let the liquid filter through. A geotechnical report helps outline soils and possible contaminants and chemicals that may need to be addressed before selecting a below-grade system.

Hydrostatic pressure

The phenomenon of hydrostatic pressure is simply the weight of the accumulated water pushing against the structure. If the soil surrounding a building is saturated with water, intense hydrostatic pressure is applied against the foundation, thereby allowing moisture to push its way through cracks and pores in the concrete walls and up through the floor slab. A metre (4 ft) of water can exert 136 kg (300 lb) of pressure per square foot of wall.

Instead of sealing a foundation against this pressure, it is much more effective and cost efficient to relieve, control, and manage it. The solution to hydrostatic pressure is to remove the water. Drainage systems—combination of grading, granular fill, control of roof bulk water, and a sump—redirect the accumulation of ground and surface water away from the foundation by channeling it to the intended location, but they are generally not enough protection. The installation of a footing drain (also known as perimeter drains) alongside a waterproofing membrane offers the highest degree of protection.

[3]

[3]A waterproofing membrane will resist hydrostatic pressure, thereby preventing water from entering the building. A drainboard provides relief from hydrostatic pressure by giving water a space to flow into, preventing much of the hydrostatic pressure from acting on the wall. Once the drainboard guides the water down to the footing (the lowest level of the foundation), the perimeter drain can carry the water away from the building, where it can no longer do any damage.

Capillary rise

Just as a dry sponge soaks up water, concrete and concrete masonry unit (CMU) walls have the capacity to wick up moisture from the footings. As Joseph Lstiburek from the Building Science Corporation[4] says, the theoretical limit of the capillary rise in concrete is 10 km (6 mi). The so-called ‘capillary rise’ is often a serious challenge in structures with concrete footings and foundation walls. According to green building expert[5] Martin Holladay, capillary rise can contribute up to 57 L (15 gal) of water a day to a building’s interior moisture load.

The Green Building Advisor journal says that the phenomenon of capillary rise occurs when the forces of adhesion are stronger than the forces of cohesion, meaning the attraction between water and wall molecules exceeds the attraction of water molecules to one another. This capillary action causes moisture in damp soil to migrate first to the footings and then up into the foundation walls.

[6]

[6]In many instances, moisture can travel several feet before the forces of cohesion and adhesion are in equilibrium. As mentioned, capillary rise may add numerous gallons of water to the moisture load inside a home. The contrast in capillarity from one material to another can even be striking. Water may rise as much as 6 m (20 ft) in certain clay soils, but only inches in crushed stone.

Capillary breaks

To avoid the adverse consequences of such moisture migration, a capillary break should be placed between the footing and the wall. Architects, designers, and contractors have two primary options when it comes to capillary breaks between basement walls and concrete footings: membranes and fluid-applied waterproofing.

Contractors should follow the manufacturer recommendations and wait before using fluid-applied products on new concrete footings. Some products may require up to a four-week wait, as the concrete must fully cure before application. The concern is such products will be prematurely applied, potentially compromising effectiveness through improper bonding and cracking. Of course, scheduling pressures are all too common. Architects who stipulate the application of a membrane as a capillary break while the concrete pour is still fresh can avoid this problem.

To facilitate the use of a membrane as a capillary break, a concrete wall should be keyed to a footing through the use of a keyway. Vertical rebar can be employed for increased structural integrity when necessary, and it is also required in earthquake zones. When vertical rebar is present, contractors often opt for fluid-applied products. However, membranes still remain a viable option.

Although there are claims an appropriate concrete additive can reduce capillary rise, many manufacturers are unwilling to make such a broad promise. For a different solution, some builders choose polyethylene sheeting under footings. However, bonding issues can make it unreliable.

Without capillary breaks between footings and the foundation walls, unhealthy conditions such as mold and poor IAQ can develop. Capillarity can also lead to the premature deterioration of materials sensitive to moisture and mold growth. In residential buildings, the effects often manifest in the form of black mold around the lowest one or two feet of the interior drywall.

Specifying the right drainage board

Drainage composites are broadly specified as critical components of a successful below-grade moisture management system. However, they often are seen as adjuncts to the main waterproofing or dampproofing course, tagged onto specifications as mere accessories. Too often treated as a commodity, the drainage products are viewed as interchangeable without any consideration of their ability to meet the required performance preferences, as outlined by the building owner.

[7]

[7]Images © SAGEOS

The geocomposite membranes (i.e. drainage boards) available on the market today consist of an extruded dimple plastic core attached to a filter fabric. The dimple cores are manufactured from one of two types of plastic—high-impact polystyrene (HIPS) or polypropylene (PP). The fabric is usually a non-woven, needle-punched PP geotextile.

All drainage composites are not created equal. Often, specifiers focus on compressive strength and geocomposite water flow rates.

These are important factors, but reliance on just these technical details can result in less than desirable performance over the life of the structure. The specifier should also consider the membrane’s durability and strength, both during the backfilling process and over the life cycle of the building it is intended to protect.

The dimple portion of drainage boards are made from one of three main types of plastic—HIPS, PP, or high-density polyethylene (HDPE).

According to ASTM D6364-06, Standard Test Method for Determining Short-Term Compression Behavior of Geosynthetics, HIPS has the advantage of delivering high compressive strength ratings. However, HIPS is not as durable as other plastics. Despite giving high compressive strength numbers in laboratory testing, it is subject to stress cracking over time when under load, leaving the waterproofing system vulnerable.

Many designers specify the drainage board by compressive strength numbers without regard for the actual requirements of the project. HIPS drainage boards are specified with, for example, a compressive strength of 8165 kg (18,000 lb)/sf. However, this requirement exists, as that is what HIPS tests at, not because of actual project requirements. For instance, in specifying a drainage board, one might see a requirement for a drainage board with 6804 kg (15,000 lb)/sf for a roof engineered for only a few hundred lb/sf.

[8]

[8]PP and HDPE show somewhat lower compressive strength numbers, per ASTM D6364-06, but provide more durability, having higher resistance to stress cracking under long-term load. Unlike HIPS, neither can be torn by hand. It is important to note flow rates through the composites remain similar to those of HIPS drainage boards. Both PP and HDPE can be more easily formed into other dimple shapes, patterns, and heights that will deliver suitable performance at appropriate cost.

This suggests specifications focusing on compressive strength as the primary performance criterion are not taking into account other important factors.

Selecting a dimpled membrane

Dimple membranes can be a suitable choice for applications less than 4 m (12 ft) in depth without hydrostatic pressure. These applications may be residential as well as multi-family or light commercial buildings where full waterproofing and drainage board systems would be overkills.

Deciding on a dimpled membrane for a foundation’s protection system is arguably the right choice for most buildings. Dimpled membranes have many advantages over other systems, including the ability to be installed over any foundation type: poured concrete, concrete block, insulated concrete form (ICF), or preserved wood foundations.

It is always best to protect a foundation at the point of installation before backfill is placed. A well-protected foundation should not require any maintenance. Digging out backfill for remediation can be quite expensive if leaks develop. Therefore, it is always best to approach a repair from the outside, since it is ideal to stop water before it enters the foundation wall. Understandably, this is not always possible when sites have zero lot lines or elaborate landscaping infrastructure. Repairing leaks from the inside is a more economical approach, but it could also be less effective. Water can move through unseen channels within the foundation once in the system. It may be stopped in one location only to arise later in another. Until water intrusion is stopped completely, any interior mold remediation will be a temporary fix since the source of moisture will remain.

Spray-applied asphalt emulsions are a common and code-compliant approach to dampproofing a foundation wall. These coatings are site-applied with effectiveness highly reliant on the installer. They are cost-effective, but do not have the ability to move with the building, leaving natural cracks in concrete exposed to potential water intrusion.

A dimpled membrane offers many benefits. Dimpled membranes provide an even application, factory-controlled quality, and the ability to bridge foundation cracks. This means no water intrusion, optimal comfort, and healthy living spaces for homeowners, and fewer warranty claims and call-backs for building owners. The dimples also create an air gap between the membrane and the foundation, which removes hydrostatic pressure from any incidental water getting behind the membrane, thus allowing the liquid to flow freely to the perimeter footing drain.

When selecting a drainage membrane, design professionals should consider the following:

- type of protection needed;

- best practices to install or secure the drainage membrane to the foundation;

- accessories, and how they affect performance;

- sag, tear, and product collapse risks;

- problem signs with the foundation protection;

- possible damages that can result from a failed drainage membrane or improper installation; and

- proper recourse if an issue arises.

[9]

[9]Images courtesy Dörken Systems

The type of protection clients can expect depends on the quality of the drainage membrane. The dimple height, sheet thickness, and compressive strength vary between manufacturers. Understanding the true requirements for the project will allow the selection of the appropriate drainage board. However, none of these moisture-resistive steps address the problem of moisture migrating from the footings into the foundation wall. Only proper capillary breaks on footings can stop this undesirable movement of water.

Waterproofing the world’s longest, deepest tunnel

The Gotthard Base Tunnel runs beneath the Alps as part of a new north-south railway in Switzerland. At 56.8 km (35.2 mi), it is the longest tunnel in the world, surpassing the Seikan Tunnel in Japan. The total is 152 km (94 mi), when service tunnels and other shafts are included. With an expected service life of 100 years, and without the need for major repairs for at least 50 years, this can be a challenging environment for drainboards.

The Gotthard Base Tunnel is a double-shell tunnel with a combination of waterproofing system and drainage layer between the shotcrete outer shell and the concrete inner shell. This design continuously drains away seepage water to protect the concrete shell against hydrostatic pressure, and to transfer high loads onto the concrete support structure.

Dealing with water seepage

Tunnel engineers faced prodigious challenges on this project, including dealing with hydrostatic pressure.

[10]

[10]At points where the tunnel burrows under 2286 m (7500 ft) of mountain cover, geothermal processes send alkaline and acidic seepage water that could be as hot as 45 C (113 F).

To handle these intense conditions, the world’s longest tunnel uses HDPE drainboards manufactured specifically for the project. These drainboards improve waterproofing by relieving hydrostatic pressure that builds up against subterranean surfaces.

Although installed in a relatively harsh environment, HDPE drainboards can retain their integrity for many decades despite unprecedented physical, mechanical, chemical, and biological demands. Since the tunnel is engineered to not require major maintenance for 50 years, the aging processes of polymeric products must be minimal.

Higher performance demands new testing

The anticipated challenges for the tunnel’s drainage systems were such that new testing methods had to be developed to address the unique qualities of the Gotthard base tunnel[11].

Traditional testing methods were reinforced by newly developed procedures that evaluated:

- aging characteristics in oxygen-enriched, high-temperature water;

- the simultaneous impact of horizontal shear and lateral loads;

- compression creep involving rough surfaces; and

- installation issues that are related to concrete outer shell construction.

The testing was conducted by a third-party using the International Organization for Standardization (ISO) tests, and was subject to the approval process of the tunnel authority.

The Gotthard Base Tunnel was a demanding project with extreme conditions. The test program comprised existing test methods that were augmented by additional procedures, such as aging resistance in oxygen-enriched water at elevated temperatures, compression creep tests between rough surfaces, tests under combined lateral loads and horizontal shear, as well as installation tests including the construction of the concrete support shell.

The selected drainboard was exposed to a variety of extreme conditions, including water heated to temperatures of up to 70 C (158 F). The drainboards were also tested using 50 C (122 F) acidic water containing ½-percent sulfuric acid and 50 C alkaline water saturated with calcium hydroxide. Oxygen-enriched water circulated at 70 C further tested the durability of the drainboards.

Samples were aged over a period of 24 months. During the aging period, the specimens had been submerged in acidic and alkaline solutions and in oxygen-enriched water before retesting. All required product specifications needed to confirm the aging properties could be met.

Conclusion

A water-managed foundation system prevents moisture buildup at the foundation wall. When there is no hydrostatic pressure, there is no need to worry about water seeping through potential cracks and pores in the concrete that will lead to mold and other moisture-related problems.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Foundation-Waterproofing_1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Foundation-Waterproofing_3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Capillary-Breark_Illustration.jpg

- Building Science Corporation: http://www.buildingscience.com/documents/insights/bsi-011-capillarity-small-sacrifices

- green building expert: http://www.greenbuildingadvisor.com/article/capillary-breaks-above-footings

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Footing-Barrier-Install_2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Drainboard_HIPS.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Drainboard_Polypropylene.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Case-Study_Gotthard-Tunnel_2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Case-Study_Gotthard-Tunnel_1.jpg

- Gotthard base tunnel: http://tunnelingonline.com/long-term-performance-of-hdpe-drainboards-in-the-gotthard-railway-tunnels

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/05/Author-Headshot_PeterB.jpg

- pbarrett@dorken.com: mailto:pbarrett@dorken.com

Source URL: https://www.constructionspecifier.com/a-systemic-approach-to-waterproofing-foundations/

[12]Peter Barrett is the product and marketing manager for Dörken Systems. He has been with the company for more than 12 years. However, his involvement with the design community and building materials industry spans over 25 years. Barrett holds a BA (Hons.) from Queen’s University, Kingston, Ontario, Canada, and an MBA from Wilfrid Laurier University, Waterloo, Ontario, Canada. Barrett is a member of the board of directors for the Air Barrier Association of America (ABAA). He can be reached at pbarrett@dorken.com[13].

[12]Peter Barrett is the product and marketing manager for Dörken Systems. He has been with the company for more than 12 years. However, his involvement with the design community and building materials industry spans over 25 years. Barrett holds a BA (Hons.) from Queen’s University, Kingston, Ontario, Canada, and an MBA from Wilfrid Laurier University, Waterloo, Ontario, Canada. Barrett is a member of the board of directors for the Air Barrier Association of America (ABAA). He can be reached at pbarrett@dorken.com[13].