Accessibility of operable windows and balcony doors

by Katie Daniel | July 12, 2017 2:08 pm

[1]

[1]by Steve Fronek, PE

To help ensure accessibility of fresh air and a connection with the outdoors for those with physical disabilities, windows capable of meeting operating force and motion requirements of International Code Council/American National Standards Institute (ICC/ANSI) A117.1, Accessible and Usable Buildings and Facilities, are being more commonly specified.

Accessibility is especially important in buildings such as skilled nursing and personal care facilities, classrooms and dormitories, and condominiums, apartments, and hotels. As noted in American Architectural Manufacturers Association (AAMA) 513-14, Standard Laboratory Test Method for Determination of Forces and Motions Required to Activate Operable Parts of Operable Windows and Doors in Accessible Spaces:

Accessible window and door units [are] operable window assemblies, including frame, infill, hardware, and all other appurtenances, required by project specifications and/or applicable codes, to be accessible to and usable by people with such physical disabilities as the inability to walk, difficulty walking, reliance on walking aids, blindness and visual impairment, deafness and hearing impairment, in coordination, reaching and manipulation disabilities, lack of stamina, difficulty interpreting and reacting to sensory information, and extremes of physical size.

(The portion in italics comes from ICC/ANSI A117.1.)

The need for accessible windows and doors is significant. According to a 2013 publication from the Centers for Disease Control (CDC), “Prevalence of Disability and Disability Type Among Adults−United States,” more than 22 percent of adults (i.e. 53.3 million people) reported a disability, with ‘mobility’ being the most frequently reported type (13 percent), followed by cognition (10.6 percent), independent living (6.5 percent), vision (4.6 percent), and self-care (3.6 percent). The study also noted a higher prevalence of disability cited by adults living in southern states, and among women compared with men. Prevalence of any disability and disability in mobility were higher among older age groups. (For more, see CDC’s Weekly Mortality and Morbidity Report[2] from July 31, 2015 [64 (29)].) While the current focus for windows and doors is on mobility, it would seem appropriate for fenestration designers to target all types of disabilities in the future.

As a general building design concept, accessibility has its roots in disciplines known throughout the years as barrier-free, universal, or inclusive design; other names have included design-for-all or aging-in-place. For clarity, this article uses the term to refer to any of these design protocols, recognizing some differences in emphasis and design criteria. Various protocols have placed more or less emphasis on the use of operable windows.

[3]

[3]Photo © Phil Weston

Understanding the U.S. codes

Operable windows intended for use in accessible spaces are often mistakenly called ADA windows. Since the Americans with Disabilities Act (ADA) is a law—and not a building code, specification, or test method—it is missing many of the necessary technical requirements for compliance testing. Some of the government agencies that have promulgated regulations to help ensure compliance include:

- U.S. Department of Justice’s (DOJ’s) ADA Standards for Accessible Design;

- U.S. Access Board’s ADA and ABA Accessibility Guidelines (ADAAG); and

- U.S. Department of Housing and Urban Development’s (HUD’s) Fair Housing Act (FHA)—which addresses door clear width and threshold height, but not operable parts of windows.

In addition to U.S. governmental agencies, local authorities having jurisdiction (AHJs) sometimes adopt accessibility requirements for operable windows, including Chicago Public Schools (CPS) and the Mayor’s Office for People with Disabilities (MOPD), as well as the New York City Building Code.

Many university housing offices have recognized the need for accessible operating windows in dormitories and other buildings. In particular, the University of Wisconsin at Whitewater is a recognized leader in addressing the special needs of its student population. Its Center for Students with Disabilities calls itself “an active partner in creating an accessible learning community where students with disabilities have an equal opportunity to participate fully in all aspects of the educational experience.”

It is not this article’s intention to summarize or interpret building code requirements or enforcement provisions, but to draw attention to important design considerations and cite relevant examples of best practices. Local AHJs should be consulted in determining applicability and in defining detailed requirements for any given structure or space.

While detailed requirements vary, generally all U.S. references cite the aforementioned ICC/ANSI A117.1 publication for window operating forces and motions.

[4]

[4]Photos courtesy Wausau Window and Wall Systems

The old: ICC/ANSI A117.1-2009

There are three types of dwelling or sleeping units of interest addressed in A117.1:

- Accessible units (most stringent);

- Type A units; and

- Type B units (least stringent).

All three cite Sections 308 and 309 of ICC/ANSI A117.1. Operating parts of windows must comply in Accessible and Type A units, unless otherwise specified by local AHJs. (Similarly, operating parts of windows need not comply in Type B units, unless otherwise specified.) As might be expected, Accessible and Type A units also ‘count’ as Type B units, since they meet more stringent requirements.

Surprisingly, requirements for operable parts of windows were first added to ANSI A117.1 in 1992, although a test method has never been referenced. Paragraph 309 of ICC/ANSI A117.1-2009 states:

309 Operable Parts

309.1 General. Operable parts required to be accessible shall comply with Section 309.

309.2 Clear Floor Space: A clear floor space complying with Section 305 shall be provided.

309.3 Height. Operable parts shall be placed within one or more of the reach ranges specified in Section 308.

309.4 Operation. Operable parts shall be operable with one hand and shall not require tight grasping, pinching, or twisting of the wrist. The force required to activate operable parts shall be 5.0 pounds (22.2 N) maximum.

Lacking a scientific test method, in one situation, the design professional responsible for acceptance testing of accessible window units creatively used the end of a 30-mm (12-in.) ruler to operate windows. The window was deemed compliant if it was possible to unlock, open, close, and lock the window with the end of the ruler while seated.

Recognizing the need for a repeatable, reproducible, and uniform test method, AAMA formed a task group and developed AAMA 513-12 to fill the void, at least for CW and AW Performance Class windows.

[5]

[5]AAMA 513 was updated in 2014 to encompass all window and door Performance Classes, as well as to address other specific requests of the ICC Consensus Committee on Accessible and Usable Buildings and Facilities (i.e. ICC Accessibility Committee).

In addition to forces and motions, the designer and specifier must ensure operable windows are located and detailed in a way that meets the ‘reach’ limitations of ICC/ANSI A117.1. Different height requirements apply to obstructed and front reach. There are also physical limits on clearances and protrusions, as well as regarding approach area and threshold height (the latter for terrace doors and sliding glass doors).

It is important to remember building codes represent only minimum requirements. Even if not required, accessible operating windows may be a very desirable feature of the occupied spaces being designed, making it easier for everyone to enjoy the fresh air.

The new: IBC 2018

The International Code Council’s 2018 edition of the International Building Code (IBC) will parallel past versions’ requirements in that, as with its 2012 incarnation, it requires:

Where operable windows are provided in rooms that are required to be accessible in accordance with Sections 1107.5.1.1, 1107.5.2.1, 1107.5.3.1, 1107.5.4, 1107.6.1.1, 1107.6.2.1.1, 1107.6.2.2.1 and 1107.6.4.1, at least one window in each room shall be accessible and each required operable window shall be accessible.

[6]

[6]

For most condominiums, apartments, skilled nursing facilities, hotels, and motels, operable windows in accessible and Type A dwelling and sleeping units must comply. It is important to keep in mind operable windows in hospital patient rooms are usually keyed, and intended solely for custodial or nursing staff operation, with emergency ventilation and egress addressed by mechanical systems and automatic smoke dampers. As yet, the special needs of staff members with physical disabilities have not been addressed relative to operable windows.

In most cases, windows are not required by code to be operable, because they are either:

- in a fully sprinklered building;

- in rooms directly opening into corridors leading to exits in two directions; or

- more than 22.86 m (75 ft) above the ground.

As such, they are not emergency escape and rescue openings (EEROs). So, if the designer prefers not to deal with operating window parts in Type A units, operable windows are not used. In some situations, this could be considered at odds with sound sustainable design practices, which would help ensure fresh air and a connection with the outdoors are made accessible to people with physical disabilities.

Most, but certainly not all, AHJs in the United States adopt IBC for new construction. For purposes of clarity, only the newest 2018 edition is addressed herein. Requirements for renovation and window replacement vary widely by jurisdiction and must be investigated on a project-specific basis.

IBC 2018 includes ICC/ANSI A117.1-2009 as a reference document, and cites its requirements as the basis for compliance. In a process spanning several years, A117.1 was updated by the ICC Accessibility Committee, and was approved for publication in January 2017, pending ANSI review. Although the updated 2017 version will not be referenced in the newest IBC, a number of significant changes to accessibility requirements for windows and doors will affect future code cycles.

The future: ICC/ANSI A117.1-2017

Most importantly, the updated ICC/ANSI A117.1-2017 standard references AAMA 513-14 to take the guesswork out of compliance determination. Other important additions and clarifications regarding windows and doors in the 2017 update include:

- maximum hardware operating forces for manually operated exterior doors along accessible routes were clearly defined—both a 67.7-N (15-lb) forward force in pushing or pulling hardware and

a 3.2 N-m (28 in-lb) rotational force to operate unlatching hardware; - to eliminate ambiguity regarding the forces and motions necessary to operate windows, it was clarified windows must open, close, lock

or latch, and unlock or unlatch, all within accessible limits (As Section 309 is titled simply “Operable Parts,” some confusion as to its applicability to both hardware operation and movement of the sash or vent has been evident in AHJ’s varied interpretations.); and - maximum operating force was increased to 37.7 N (8.5 lb.) for vertical and horizontal sliding windows, remaining at 22.2 N (5 lb.) for all other types. (It was deemed unrealistic to expect sliding-seal double-hung and horizontal rolling/sliding windows to meet the same maximum operating force as compression-sealed window types.)

(Some exceptions apply.)

[7]

[7]Photo © Nels Akerland

Examining the AAMA 513-14 test method

The purpose of the AAMA 513-14 laboratory test method is to demonstrate whether a given window unit (as designed) is capable of being operated with forces and motions consistent with ICC A117.1 limitations when properly installed, adjusted, and maintained.

Operation of any window includes four actions:

- unlocking or unlatching;

- opening the sash or vent;

- closing the sash or vent; and

- locking/latching.

As previously noted, all four actions must meet accessibility requirements for force, motion, and reach. They must also be performable using one hand.

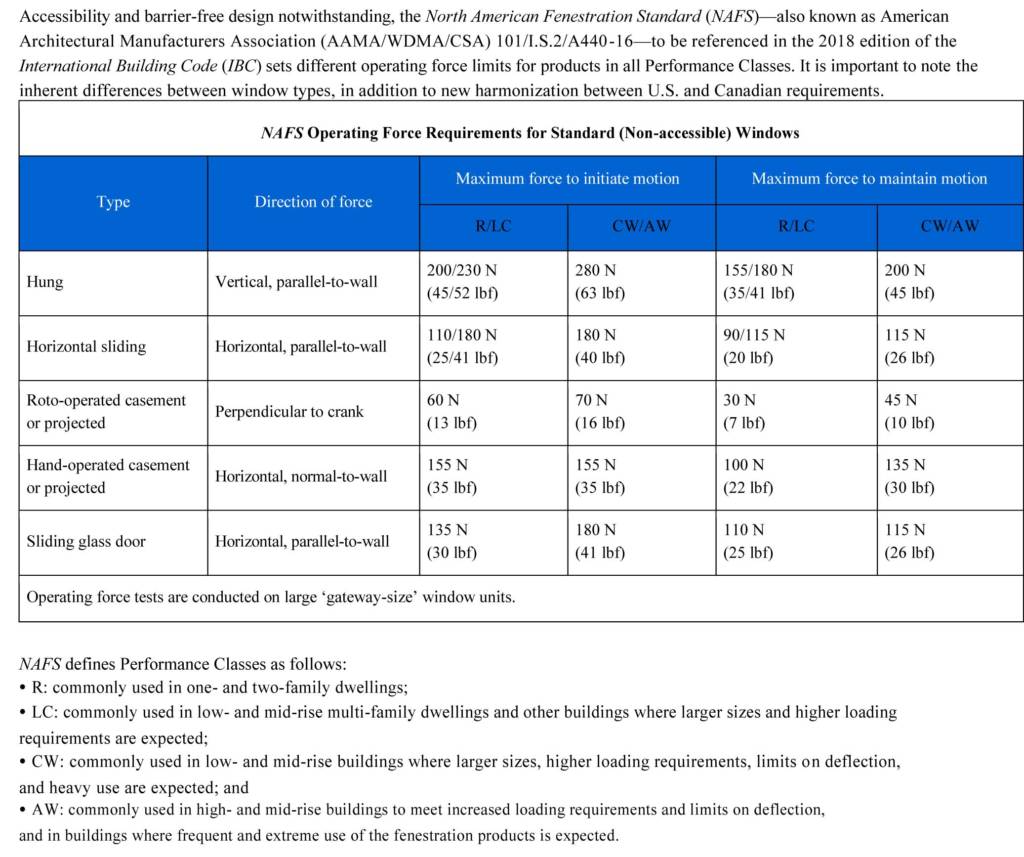

Tests are run on all classes’ large gateway-size windows, or the alternative minimum test size in the case of R Performance Class. (For more on classes, see “NAFS Operating Force Limitations.”) By grouping accessibility testing of hardware and weather seal packages, used across a range of individual products, one test assembly can qualify multiple individual products. AAMA 513 is a useful lab method, eliminating the variables of wind and weather that could affect operating force onsite, as well as addressing critical issues such as sampling, measurement precision, test equipment, methodology, and inspection. An Appendix addressing field testing was added in the most-recent update to AAMA 513.

Some manufacturers’ accessible windows perform the same as standard operable windows, with no reductions in air, water, thermal, or structural performance necessary. However, AAMA 513-14 allows some leeway, given the low locking forces and friction required to keep forces below ICC/ANSI A117.1 limits. As noted in AAMA 513:

For accessible units, certain “reductions” in air infiltration and water resistance performance requirements shall be permitted, when compared to conventional testing, given the desirability of minimizing operating forces.

[8]

[8]Photos courtesy Wausau WIndow and Wall Systems

Air infiltration: 1.5 times the maximum air infiltration specified in AAMA/WDMA/CSA 101/I.S.2/A440, for the type and class tested shall be allowed.

Water resistance: Unless testing to limited water “LW” rating, conduct laboratory water penetration resistance testing at 15% of the inward-acting design pressure for the project for R, LC and CW Class products, or 20% of the inward acting design pressure for the project for AW Class products, but not less than:

- 140 Pa (2.92 psf) for R Class products;

- 180 Pa (3.76 psf) for LC Class products;

- 220 Pa (4.59 psf) for CW Class products; or

- 390 Pa (8.15 psf) for AW Class products.

Structural integrity: Design loads shall be based on project requirements, or the following minimums, whichever is greater:

- 720 Pa (15.04 psf) for R Class products;

- 1200 Pa (25.06 psf) for LC Class products;

- 1440 Pa (30.08 psf) for CW Class products; or

- 1920 Pa (40.10 psf) for AW Class products.

Design load shall not necessarily be based on the performance requirements of AAMA/WDMA/CSA 101/I.S.2/A440 applicable to optional performance grade ratings, unless specified otherwise.

The AAMA publication offers the following language for specifiers’ use:

Accessibility: As indicated on architectural drawings or project specifications, operable windows and doors as required in occupied spaces shall meet the operating force limits and motion restrictions of ICC A117.1, Section 309.4, when tested by an AAMA-accredited lab in accordance with AAMA 513-14.

All code-required operable windows in a given occupied space may be required to meet these restrictions.

[9]

[9]Product design

It should not be expected standard off-the-shelf operable windows can be adjusted to meet accessibility requirements, even if properly located in plan and section. Especially on large windows, achieving ease of operation with restricted motion will likely require specially designed compression weather-seals and low-friction hardware components. Hardware must be selected that ensures windows do not fall shut under their own weight or require two hands to hold closed and lock simultaneously.

Accessible project-out awning vents cannot usually be manually operated due to the requirement for hold-open friction. Out-swing casement vents cannot be hand-operated due to the requirement for one-hand operation. Roto- or swing-arm operators can be provided for both of these vent types, providing mechanical advantage to overcome friction, helping lift the weight of glazing infill, and keeping the operating handle within reach limitations. Special placement of operating handles to achieve low forces may restrict maximum opening.

Project-in hopper vents require glass to be lifted, and typically are not fitted with roto-operators.

Hung windows require the occupant to lift the sash to open, as well as apply added force to overcome friction of sliding weather-seals. Counterbalancing devices may not provide adequate force assistance to get large windows to operate at less than 37.7 N (8.5 lb). Similarly, operation of horizontal sliding sash requires both inertia and weather-seal friction to be overcome. This can limit the applicability of large, manually operated hung and sliding windows in accessible spaces even under new, relaxed ICC/ANSI A117.1 limits.

It is important to keep in mind motorized and mechanical operators have long been available for almost any window type—single- and double-hung, horizontal sliding, parallel-opening, or dual action; as well as the aforementioned projected vents. As long as forces and motions necessary to activate and operate motorized and mechanical features meet the requirements of ICC/ANSI A117.1, these may be deemed accessible operator types.

Use of insect screens may limit accessibility options for certain vent modes and hardware packages. Typically, controls and cords for blinds, drapes, or shades are not required to be accessible.

Operable windows must be located and detailed in a way that meets the reach limitations of ACC/ANSI A117.1 .

[10]

[10]Photo © Nels Akerlund

Installation and maintenance

Production-line testing of operating force can help ensure that thewindows leaving the factory comply with AAMA 513-14 requirements. Accessible operating window products require additional care in installation, final adjustment, and maintenance to achieve and maintain compliance. Plumb, square, and level installation is critical. Building settlement can affect operating forces, and necessitate post-installation adjustment.

Standard operable windows cannot always be adapted to achieve accessibility at a later date. The necessary fieldwork varies widely with application and window type—it may be as simple as hardware adjustment, or virtually impossible without complete reconfiguration of window openings and surrounding conditions. If adaptability is desired, the design team is strongly encouraged to develop a window accessibility plan early in the design process, then detail and specify products accordingly.

Terrace and patio doors

The same subcontractor providing windows also often provides doors for access to balconies, terraces, and patios. However, accessibility requirements for doors are somewhat more complex than for windows.

Balcony doors required to be accessible must comply with all requirements of ICC/ANSI A117.1 Section 404. These include:

- reach limitations;

- one-hand operation without grasping, pinching, or twisting of the wrist; and

- maximum 22 N (5 lbf) of operating force to open, not including latching hardware. (The Chicago Building Code has increased the operating force requirement to 38 N [8.5 lbf].)

Door closer manufacturers offer accessible options that limit force-to-open and closing lag time.

As noted, hardware operating force requirements were clarified in the recent ICC/ANSI A117.1 update. Ninety-degree thumb-turn locks are typically made standard on manufacturers’ swinging terrace doors for compliance.

Additionally, threshold height is limited along accessible routes. A minimum width, turning/approach area, and low protrusion limits, as well as requirements for kick plates on swing doors also apply.

Code requirements notwithstanding, accessible terrace and patio doors may be a very desirable feature of the spaces being designed, making it easier for all occupants to enjoy balcony spaces with easy-to-operate door panels and lower-profile thresholds.

| THE NEW YORK CITY BUILDING CODE |

| As with any code issue, the local authority having jurisdiction (AHJ) makes the final rules, and New York City represents a special case for accessibility of operable windows. While the 2014 New York City Building Code is patterned after the 2012 edition of the International Building Code (IBC), it also differs in some significant ways. The first is in its requirement for natural ventilation, and hence for operable windows of a specified size in habitable or “occupiable” spaces, defined as:

Habitable space. All rooms and spaces within a dwelling unit in Group R or I-1, including bedrooms, living rooms, studies, recreation rooms, kitchens, dining rooms, and other similar spaces. Occupiable space. A room or enclosed space other than a habitable space, designed for human occupancy or use, in which individuals may remain for a period of time for rest, amusement, treatment, education, dining, shopping, employment, labor, or other similar purpose. The second significant difference is in New York City’s requirements for Type B+ dwelling and sleeping units. 1107.2.4 Type B unit operable windows in R-2 occupancy. All operable windows required to provide natural ventilation and/or emergency escape or egress openings in rooms or spaces in the type B+ NYC dwelling unit or sleeping unit shall comply with Section 1003.13 (Windows) of ICC A117.1. Section 1003.13 of International Code Council/American National Standards Institute (ICC/ANSI) A117.1, Accessible and Usable Buildings and Facilities, in turn requires compliance with Sections 309.2 and 309.3 for clear floor space and height respectively, but not 309.4 for forces and motions. Adaptive devices to address reach limits can be used to comply in units occupied by persons with physical disabilities. In anticipation of updated standards, most design professionals are now requiring accessible operable windows in condominiums and apartment buildings in New York City, although ambiguities in ICC/ANSI A117.1-2009 provisions has made interpretation somewhat challenging. Requirements are accelerating product development and compliance testing efforts at most manufacturers serving the huge New York City condominium and apartment market segment. |

Sales representations

AAMA 513 notes:

No test method provides sufficient basis for a manufacturer to represent an individual component, product or product line, as “-certified,” “-approved,” or “-compliant,” as the Americans with Disabilities Act (ADA) makes no provisions for, nor outlines any requirements for, such certification, approval, or compliance verification.

Credible manufacturers are careful to represent laboratory-tested products as capable of accessible operating forces and motions, when properly installed and adjusted, without making any unverifiable claims.

In addition to standard disclaimers and qualifications, manufacturers should make claims of neither ADA compliance of the total window or door installation onsite (including hardware, approach area, reach, forces, or motion), nor acceptance by AHJs. These are clearly outside window manufacturers’ control, since they depend on installation and field conditions such as wind, architectural design, floor plans, wall sections, and programmatic considerations.

Conclusion

Whether required by code or not, accessible operating windows and balcony doors may be a very desirable feature of occupied spaces in skilled nursing and personal care facilities, condominiums, apartments, and hotels, or classrooms and dormitories. Accessible operating windows help ensure fresh air and a connection with the outdoors are made accessible to people with physical disabilities. Product development and compliance testing efforts at most manufacturers are underway to provide a broad selection of accessible window types, both manually operated and motorized.

Steve Fronek, PE, leads Wausau Window and Wall Systems’ new product development, marketing, technical support, and general research. He is the past-president of the American Architectural Manufacturers Association (AAMA), and has served on 16 of AAMA’s committees and task groups, including guiding the evolution of thermal performance standards as they exist today. He can be contacted via email at sfronek@wasauwindow.com[11].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_IL_Loyola-CSUL-SanFran_AllianceGlazing4.jpg

- Weekly Mortality and Morbidity Report: http://www.cdc.gov/mmwr/preview/mmwrhtml/mm6429a2.htm

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_WI_VA_ext_PhilWeston.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_RotoForceToOpen-e1499881262342.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_ADA_Hardware.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/NAFS_image.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_WI_UW-Whitewater_NelsAkerlund3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_Students.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_LeverHandle.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Wausau_WI_UW-Whitewater_NelsAkerlund2.jpg

- sfronek@wasauwindow.com: mailto:sfronek@wasauwindow.com

Source URL: https://www.constructionspecifier.com/accessibility-of-operable-windows-and-balcony-doors/