Adhered Manufactured Stone Veneer: Manufacturing performance for the winter

A weep screed should also be installed at the foundation termination, between foundation and framing, to allow moisture that might accumulate behind the AMSV to escape. In most cases, the weep screed provides a 101-mm (4-in.) clearance from grade or a 51-mm (2-in.) clearance from any paved surface.

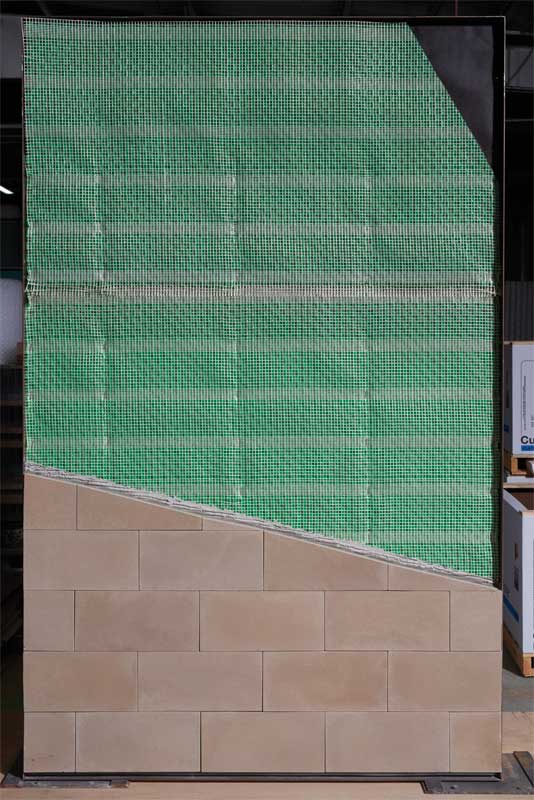

Lath is also needed—if the framing in framed construction is the skeleton of the building, then lath is the skeleton of the adhered veneer system. Many choices are available when it comes to lath, from expanded metal and woven and welded wire to fiberglass. Since this component is so critical to the performance of the system, this is not a good place to cut corners in materials or installation. It is important to consider manufactured stone, mortar, and lath can weigh up to 11 kg per 0.1 m2 (25 lb/sf), and the lath and its attachment will carry this load to framing.

Also popular are rainscreen systems, which provide a larger physical air space between the WRB and the cladding. Such systems are made from several materials and layers, including WRB, lath, sheathing, and exterior cladding. The key is the large drainage plane (usually 6 mm [¼ in.]), which allows moisture to easily drain to the weep screed. With this technique, nearly unobstructed drainage and ventilation drying can be achieved.

Installation conditions

To create an environment for a successful installation of AMSV, ambient temperatures—as well as the temperature of the substrate and all materials used at installation—must be considered. Accepted air temperatures for installation are between 4 and 32 C (40 and 90 F), with ideal conditions hovering at about room temperature.

When these conditions do not exist naturally, a temporary controlled work environment should be created to maintain the temperature. Failure to do so may result in a poor application and can lead to mortar and grout failure, especially in harsh climates with extensive rain, snow, and repeated freeze-thaw cycles. It is acceptable to install AMSV wet, but frozen AMSV or that with visible ice is not.

Mortar and grout

Choosing the right mortar and grout is important for any AMSV installation. During especially cold conditions, it becomes even more critical. Additives can improve mortar performance within these temperature ranges, but it is still critical to follow manufacturer instructions and verify additives will not negatively affect lath durability or cause efflorescence issues. All materials should be acclimated to the controlled temperature at least 24 hours before beginning work.

Also, curing time is slower during cold weather. With temperatures between 4 and 10 C (40 and 50 F), it can take 72 to 96 hours for mortar to set sufficiently. For a durable installation, grout should not be installed until mortar has set completely.

Mortar systems using modifiers in the mix are stronger and more deformable in cold-weather installations. Their high polymer content adds increased bond and flexural strength as well as offering more working time, making them an excellent option in climates where temperatures remain below freezing for several months. The requirements of such modified standard mortars are detailed in ANSI A118.15, American National Standard Specifications for Improved Modified Dry-set Cement Mortars, and A118.4, American National Standard Specifications for Modified Dry-set Cement Mortar.

Eliminating voids

One of the best ways to weatherproof an AMSV installation is to ensure all mortar voids are eliminated during the installation process. There should be no areas between the wall and the AMSV where water might enter or collect.

A multistep process is employed, beginning with a scratch coat, which accomplishes two primary functions. First, by fully encapsulating the lath with a mortar scratch coat, the amount of water and air that can reach the lath is minimized. The mass of the total scratch coat combined with setting bed mortar and AMSV units provides the capability to manage water through absorption and evaporation. The scratch coat should be 13 to 19 mm (½ to ¾ in.) thick.

Next, the setting bed mortar is applied. The goal is to create a uniform layer of mortar to completely cover the scratch coat and bond stones to the system. A minimum of 345 kPa (50 psi) shear bond strength is required both in ICC-ES AC51 and ASTM C1670. The basis for this requirement is pulled from the Masonry Society (TMS) 402, Building Code Requirements and Specification for Masonry Structures, sections 12.1 and 12.3. This process helps eliminate voids within the mortar layers that could capture water. Captured water can freeze and cause units to de-bond and sometimes spall.