by Michael McAuley

Plastic foams for thermal insulation have been available for more than 70 years. Extruded polystyrene (XPS) was introduced in 1943, followed by expanded polystyrene (EPS) in 1950, and polyisocyanurate (polyiso) in 1954. (For more information, see Dávid Bozsaky’s “The Historical Development of Thermal Insulation Materials” at periodicapolytechnica.org). Over the years, manufacturers have expanded these basic foams into a range of faced and un-faced products, with numerous options including fanfold bundles, composite panels, and specialty insulations with built-in drainage channels. Recently, a new class of rigid foam has become available: graphite polystyrene (GPS).

To further boost the thermal performance of EPS insulation, GPS integrates high-purity graphite throughout the EPS polymer matrix (insulation bead). With graphite being the most thermodynamically stable form of carbon, GPS achieves impressive thermal properties when the bead is expanded with air (not a chemical reaction) into a solid rigid insulation. (See “Chemistry in Its Element: Carbon,” an interview with Katherine Holt posted on the Royal Society of Chemistry website at www.rsc.org).

The addition of the graphite results in an insulation that can provide the same or greater R-values as EPS, but in a thinner product. This makes GPS insulation suitable for use in space-constrained areas and in colder climates. Another benefit is the graphite in GPS insulation enhances the material’s R-value as temperatures decrease.

In the same way XPS products are recognized by a range of primary colors, GPS is readily distinguished by its gray/platinum hue.

GPS performance attributes

While its chemistry starts with an EPS-based product, GPS insulation expands on EPS performance in two primary ways: R-value and water absorption. These factors, and other specification criteria for GPS, are discussed in the paragraphs that follow.

R-value

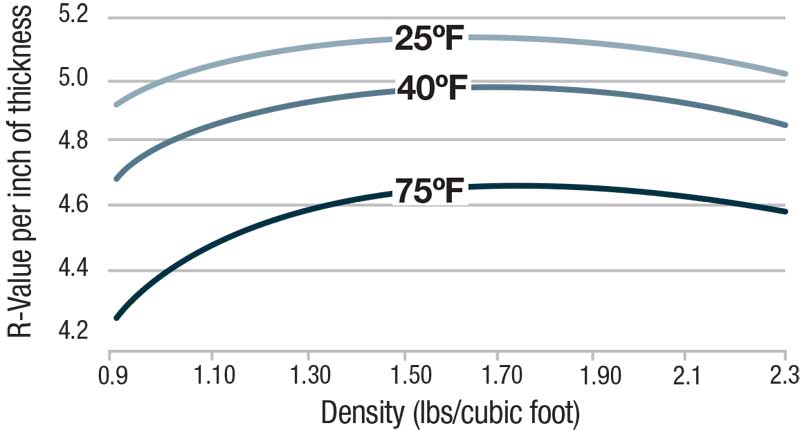

The graphite in GPS reflects radiant heat energy, which can enhance the insulation’s R-value as the temperature decreases. The R-values for GPS range from 4.7 to 4.9 per 25 mm (1 in.) of thickness at 24 C (75 F) and from 5.1 to 5.2 per 25 mm (1 in.) of thickness at −4 C (25 F), as shown in Figure 1.

As a result, GPS works well in space-constrained areas in commercial buildings, such as in cavity walls and for exterior sheathing applications.

Image courtesy Insulfoam

Similar to EPS, various manufacturers produce GPS with blowing agents that do not diffuse during the insulation’s time in service, so the insulation does not experience thermal loss as do some rigid insulations. Consequently, the R-value at time of installation is what will be provided years later—this is very important for long-term energy savings in buildings.

Breathability and moisture absorption

Compared to some thermal insulations that retain moisture, GPS is vapor-permeable, making it a breathable material. Since water vapor can pass through GPS, the insulation readily releases moisture from walls and foundations. This not only ensures thermal performance for the insulation, but it also helps reduce the potential for any moisture degradation of structural elements.

EPS dries quickly and has minimal long-term moisture retention, and the graphite in GPS further enhances this moisture performance. GPS absorbs one percent (or less) moisture by volume compared to approximately five percent for EPS and up to 19 percent for XPS.

Compressive strength

GPS insulation has similar compressive strength values as EPS, as the graphite does not change the material’s compressive resistance. For commonly available GPS products, compressive strength ranges from 69 to 228 kPa (10 to 33 psi) at 10 percent deformation, which is suitable for a wide range of building envelope applications.

Flexural strength

Similar to compressive strength, the graphite in GPS does not alter flexural strength compared to EPS. The typical flexural strength range is 172 to 483 kPa (25 to 70 psi), depending on the product type. Similar to EPS, GPS performs well at being handled during installation without being damaged.

“EPS dries quickly and has minimal long-term moisture retention, and the graphite in GPS further enhances this moisture performance. GPS absorbs one percent (or less) moisture by volume compared to approximately five percent for EPS and up to 19 percent for XPS.”

My understanding has been that closed-cell XPS is the best product in terms of resisting moisture absorption. Is this not true? Does the 19 percent number above refer to open-cell foam? Are the new graphite products open, or closed cell?

A compelling point not mentioned in the article is that the blowing agent for EPS (presumably the same for GPS) is not a high GWP (global warming potential) gas. This makes it an excellent choice compared to XPS, the most common blowing agent of which has a very high GWP rating, and takes thousands of years to dissipate in the atmosphere. We need to start taking this into account in the selection of our construction materials.