by Richard Filloramo, B.S. Arch, A.S. CT

Designers are creating new and exciting contemporary masonry designs that demand clean, smooth wall plane elevations. One challenge that can interfere with unobstructed aesthetics is the visual effects of masonry drip-edge flashing. This potential obstacle has also carried through to traditional masonry design. Designers and specifiers can find it difficult to balance design and functional water management requirements.

An exposed metal drip edge diverts water and snowmelt away from the wall below, and prevents it from re-entering the wall. At relieving angles and lintels, a drip edge will direct water away from sealants joints, which can be a source of water infiltration if not maintained over time. Drip edges also:

- protect steel lintels from corrosion;

- help minimize stains on the masonry (especially below louvers);

- provide assurance that flashing has been installed; and

- prevent capillary action of moisture moving up through the masonry (also referred to as ‘rising damp’) when it is in contact with grade.

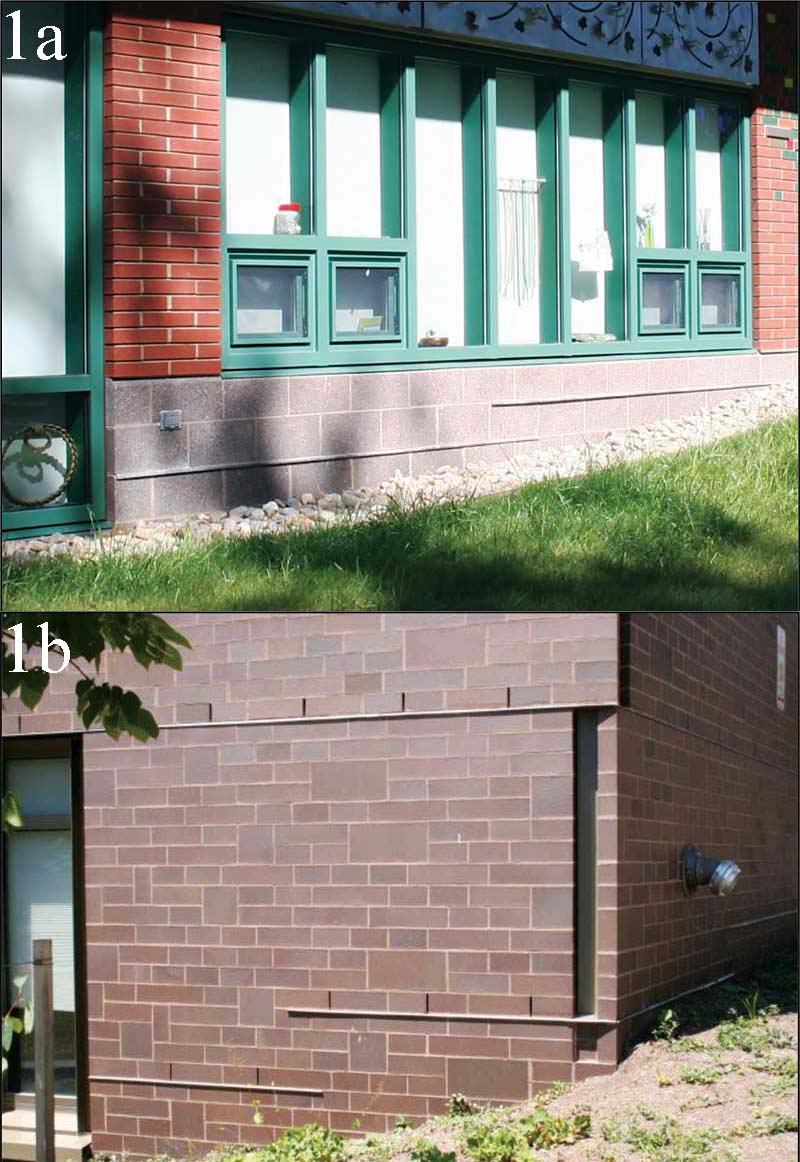

However, drip-edge flashing at highly visible building locations can create aesthetic concerns, as shown in Figure 1.

New masonry flashing details, materials, and moisture control systems have enabled designers to provide water management solutions without sacrificing aesthetics. This article will provide details, specifications, and explanations for a variety of flashing details that can enable code-compliant water management flashing systems without aesthetic interference.

Understanding the codes

Chapter 14 of the 2012 International Building Code (IBC) provides requirements for exterior walls. Section 1403.2−Weather Protection requires exterior walls provide:

- a weather-resistant exterior envelope;

- flashing, as described in Section 1405.4;

- a design preventing water accumulation;

- a water-resistive barrier (WRB);

- a means for draining water that enters the assembly to the exterior; and

- protection against condensation.

Photos courtesy Rick Filloramo

While the code lists exceptions, the basic compliance to these provisions is still required. For example, one exception notes a weather-resistant wall envelope shall not be required over masonry walls designed in accordance with Chapter 21−Masonry. However, this does not relieve the designer from complying with the weather protection requirements, as Chapter 21 established prescriptive and engineering design of masonry and does not address weather resistance. Chapter 21 also requires compliance with Building Code Requirements for Masonry Structures (i.e. The Masonry Society [TMS] 402-11/American Concrete Institute [ACI] 530-11/American Society of Civil Engineers [ASCE] 5-11) and Specifications for Masonry Structures (TMS 602-11/ACI 530.1-11/ASCE 6-11). Chapter 6–Veneer, Section 6.16 of that first document requires the design of masonry veneers to resist water penetration.

Air, moisture, and vapor control requirements are also included in Chapter 14 and in the International Energy Conservation Code (IECC) and American Society of Heating, Refrigeration, and Air-conditioning Engineers (ASHRAE) energy codes.

Flashing requirements

It is important to review IBC section 1405.4:

1405.4−Flashing. Flashing shall be installed in such a manner so as to prevent moisture from entering the wall or to redirect it to the exterior. Flashing shall be installed at the perimeters of exterior door and window assemblies, penetrations, and terminations of exterior wall assemblies, exterior wall intersections with roofs, chimneys, porches, decks, balconies and similar projections, and at built-in gutters and similar locations where moisture could enter the wall. Flashing with projecting flanges shall be installed on both sides and the ends of copings, under sills, and continuously above projecting trim.

1405.4.1−Exterior wall pockets. In exterior walls of buildings or structures, wall pockets or crevices in which moisture can accumulate shall be avoided or protected with caps or drips, or other approved means shall be provided to prevent water damage.

1405.4.2−Masonry. Flashing and weep holes in anchored veneer shall be located in the first course of masonry above finished ground level above the foundation wall or slab, and other points of support, including structural floors, shelf angles, and lintels where anchored veneers are designed in accordance with Section 1405.6.