Standards for schools

The acoustical design standards for classrooms developed by ANSI through ASA differ from those for other commercial and institutional buildings. ANSI/ASA S12.60, Acoustical Performance Criteria, Design Requirements and Guidelines for Schools, states the minimum set of requirements to help school planners and designers provide good acoustical characteristics for classrooms and other learning spaces. (The standards are available for free download at www.acousticalsociety.org). These requirements for permanent classrooms are based on room size and include maximum background levels for A- and C-weighted sound pressure levels (dBA and dBC) and reverberation time.

A growing number of states are adopting the ANSI/ASA standards, signifying the increasingly important role of acoustics in school design and planning. The U.S. Access Board, a federal agency that promotes equality for people with disabilities, is also working to get the standards adopted into building codes across the country. The Access Board recently collaborated with the International Code Council (ICC) to put the criteria determined by ANSI/ASA into the building codes dealing with accessibility. ICC is working on putting these requirements into the International Building Code (IBC) currently being written and to be published in 2018. (Currently, the accessibility references can be found in 1207.1 and 1207.3.) Additionally, there are standards from the Air-conditioning, Heating & Refrigeration Institute (AHRI) dealing with the recommended sound ratings of HVAC equipment used in schools.

Testing done by this author’s company in a simulated classroom environment showed the recommendations of the standard can be easily met using commercially available, off-the-shelf HVAC products and industry-accepted design and installation techniques. Acoustics are a design parameter and must be dealt with during the design of the project.

The systems tested included a packaged rooftop unit, a blower coil air-handler, and a high-efficiency water source heat pump. Testing proved the standards could be met at a less than one percent additional cost for typical installations, demonstrating the importance of considering good classroom acoustics at the start of a project.

Technology for quieter classrooms

Being aware of the specific acoustic requirements for schools—and understanding how they are different than those used for other buildings—is the first key step in planning for and addressing classroom noise levels during the design phase. One challenge faced by many schools is the need to put equipment in the classroom while still having it be quiet enough to meet acoustic standards. In these cases, placing the equipment in a small closet, an enclosed mechanical room, or above a nearby corridor can help decrease the noise level for the teacher and students.

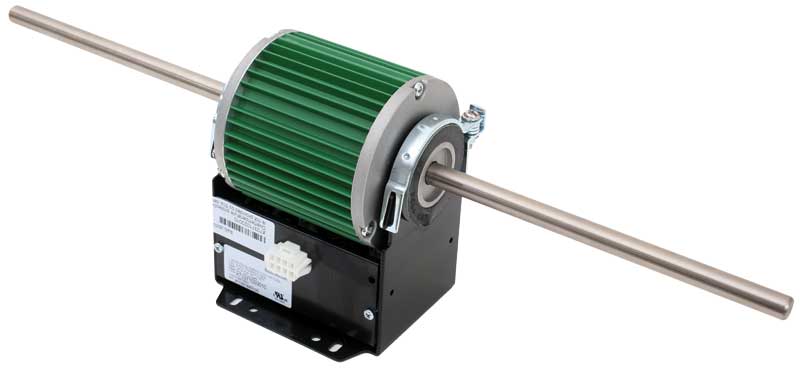

When those options are unfeasible, it becomes a matter of selecting quieter mechanical products.7 (Price points can vary from no change over traditional equipment to increasing that initial price tag. It is important to do a lifecycle cost analysis for each project. For example, electronically commutated motor [ECM] technology has a larger up-front expense, but offers better lifecycle costs because of how efficient they are). It is important to look for equipment that is AHRI-rated and labeled to ensure it meets specific acoustic specifications. It is also critical to ensure the acoustic rating is for the whole unit, rather than for just one component, such as a fan or compressor. Manufacturer testing of the entire assembled air-handling unit (AHU) is a recommended practice to provide the most accurate and reliable acoustic data.

Another option for decreasing the noise level of HVAC and mechanical equipment is to implement various acoustic treatment options. These solutions include using duct lining materials and silencers to help achieve lower sound levels. Additionally, significant progress has been made by the industry in developing ultra-quiet technologies, such as a recently introduced air-cooled chiller that is 8 dBA lower than others on the market.

Electronically commutated motors (ECM) technology can also help ensure quieter equipment performance by allowing the unit to be programmed to vary the motor speed and power. This enables the equipment to run at a lower, and typically quieter, speed when necessary—this reduces sound levels in classrooms while they are occupied.

Larger schools can consider the option of installing a centralized chiller plant, which can be placed at a location farther away from classrooms, in order to help minimize the acoustical impact on critical learning environments.

Investing in quieter HVAC and mechanical equipment can provide benefits in other ways as well. For example, selecting quieter equipment may reduce construction requirements and necessary investment in thicker windows or ceiling acoustic treatments.