by Raymond Ting, PhD, PE

by Raymond Ting, PhD, PE

In the first part of this look at air-loop window walls, this author discussed the importance of solving problems by eliminating causes. In the article, nine potential problems with traditional exposed and covered slab-edge designs were explored.

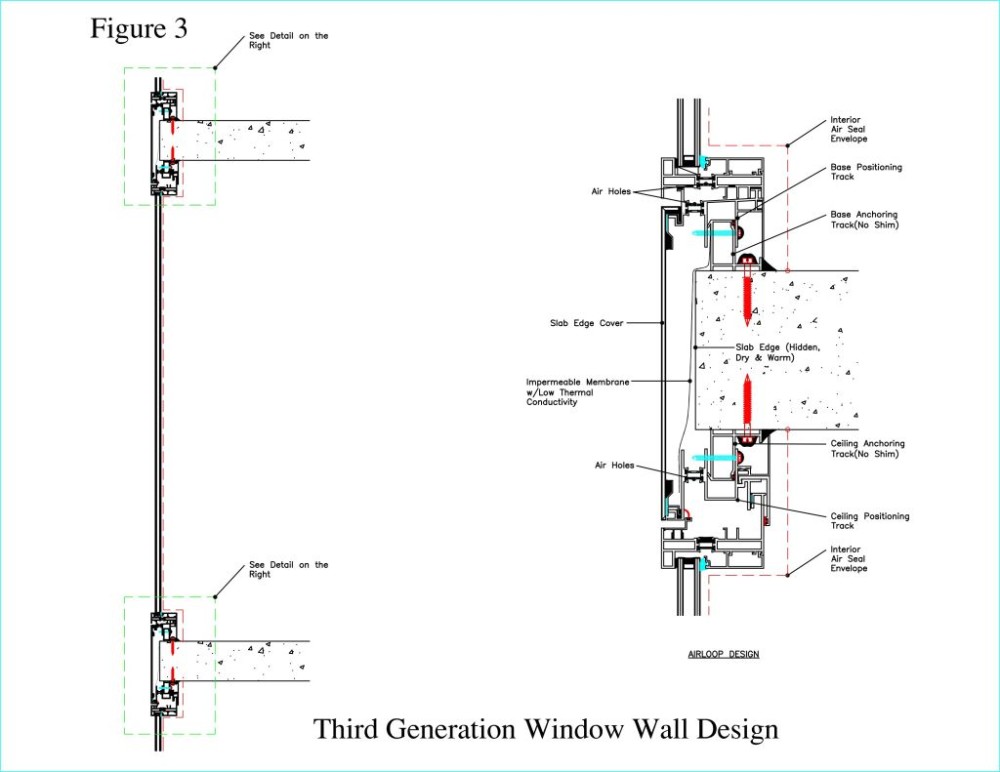

All these problems could be solved by eliminating their causes, rather than dealing with their effects. In order to understand the unique solution methodology of the air-loop design (shown at right), it can be useful to consider the following extreme example. A parasol prevents excessive sun exposure on one’s skin—this is ‘designing for the effect,’ but it does not eliminate the sun exposure. However, if one were to shoot down the sun (i.e. ‘eliminating the cause’), then the problem is solved forever, and one no longer needs a parasol. (Of course, shooting down the sun might present other problems…)

Finding the solutions

The following solution methodology makes this type of ‘forever solution’ possible:

Step 1: Analyze to determine the real causes of the problem.

Step 2: Use the functional isolation concept (FIC) to separate the causes.

Step 3: Eliminate the separated causes one by one.

This article examines how the air-loop style of window wall can speak to nine common glazing assembly problems by eliminating their causes.

1. Aesthetic problem

Steps 1 and 2: This is a ‘single-cause’ problem, so there is no need for these steps.

Step 3: The cause is eliminated by providing a slab-edge cover—the same solution already found in window walls employing covered slab-edge design.

2. Durable sealing integrity problem

Step 1: Since critical seals cannot last forever, they are the cause of the problem.

Step 2: The critical seal is required due to the double functions of sealing water (infiltration by positive wind pressure or water head pressure in the internal gutter) and sealing air at the same location. Applying FIC means the function of sealing water must be separated from the function of sealing air.

Step 3: The critical seal (i.e. ‘cause’) is eliminated in the air-loop window wall assembly because the air and water seals have been completely separated with instantaneous water drainage.

3. Health problem

Steps 1 and 2: This is a single-cause problem, so there is no need for these steps.

Step 3: The problem is forever solved due to no possibility of water being trapped within the joint cavities for any substantial duration thanks to open-joint design with instantaneous drainage in the air-loop system.

4. Design flexibility problem

Step 1: There are two design functions for the exterior wall surface terminating at the slab surfaces along the base and ceiling tracks: aesthetics and sealing on the exterior wall envelope. To eliminate the aesthetic problem of the protruding exposed slab edge, the exterior wall envelope must be pushed outwardly beyond the slab edge, with a cover installed and field-sealed to restore the exterior wall sealing envelope. The quality of field-executed sealing envelope can be highly questionable.

Step 2: Applying FIC, the aesthetic function must be isolated from the exterior sealing envelope function for the installation of the slab edge cover.

Step 3: In an air-loop system, the locations of structural connection and air-seal envelope are located near the interior surface of the wall with exterior open joints and pressure-equalized joint cavities, with instantaneous drainage mechanism eliminating the sealing function of the slab edge cover. Therefore, this problem can be forever-solved by simply pushing out the exterior wall surface to be flush with the slab-edge cover.