Analyzing bacterial growth on vinyl and polished concrete

by arslan_ahmed | March 31, 2023 4:00 pm

[1]

[1]By Mallory A. Westbrook and Jon S. Belkowitz, PhD, PE

Pathogen growth is a common financial problem that has a devastating impact in grocery stores, hospitals, retail stores, as well as schools. The root cause is due to exposure to contaminated food, settlement of airborne bacteria, and pathogens from spilled/dripped human fluids.1 Common bacteria that cause these outbreaks include E. coli, Salmonella, Listeria, Staphylococcus aureus, and more.

A report from the University of Minnesota estimated Salmonella and E. coli costs the United States $3.13 billion a year.2 A separate report from the National Center for Biotechnology Information (NCBI) found the cost of a single foodborne outbreak ranged from $3968 to $1.9 million for a fast-food restaurant and up to $2.6 million for a fine dining restaurant.3 Based on recent data, one outbreak will monopolize 621 weeks or 12 years’ worth of sales for the average grocery store.4

When compared to the average profit from grocery stores, these costs are devastating. According to Food Marketing Institute, the net profit for the average location operating within the retail grocery industry is just 1.1 percent due to these outbreaks. It is imperative for stores, restaurants, schools, and restaurants to prevent these losses by minimizing pathogen growth and outbreak.

An extremely common foodborne pathogen present in produce is listeria. The medical costs associated with listeria infections run from $61.7 to $64.8 million. In addition, productivity losses were estimated to run from $125.8 to $154.4 million a year. The productivity costs associated with listeria-related chronic illness was estimated to be an additional $38 million a year.5 In total, exposure to listeria costs $232.7 million to $264.4 million annually.

Concrete floors

Flooring is a huge contributor to pathogen growth in these environments. Most restaurants, schools, stores, and hospitals utilize concrete floors, polished concrete floors, or vinyl composite tile (VCT). Concrete floors are often placed due to the durability and ease of cleaning spills. However, concrete is rarely fully cleaned and teams up with harmful pathogens.

The concrete composite acts as a hardened sponge with interconnecting pores and is extremely permeable due to this structure. Within the body of a concrete floor slab are air voids, pores, and capillaries. Even when the void structure within the concrete is discontinuous, moisture remains present within the slab and can migrate within the body of the concrete in an adsorbed or condensed state by surface diffusion.

[2]

[2]Immediately after mixing the concrete, the pores are highly connective and large, allowing for ample amounts of water and contaminates to pass through the body of the concrete. As the hydration reactions begin with the cement and water, the cement particles begin to stiffen and allow less water to travel through the pores. This continues until the hydrated cementitious structure is formed and the initial hardening of the concrete occurs. Finally, the cement gel forms as concrete hardening is initiated and the pores and capillary cavities are connected through the body of the concrete.

Concrete is a porous material, and the degree of porosity and permeability is directly related to its composition. According to the American Concrete Institute (ACI), porosity is a measure of the volume of voids in concrete. Permeability is the rate of flow of moisture through concrete under a pressure gradient. Therefore, concrete which is more porous tends to be more permeable. The more permeable the concrete surface is, the more moisture and pathogens can penetrate into the surface of the floor and continue to grow and thrive.

The degree of surface porosity is of great concern to the presence and growth of pathogens in the surface region of a concrete slab. A highly porous surface region of a concrete slab allows for the penetration of pathogens not often completely removed by routine maintenance cleanings. Once pathogens penetrate the surface, even extreme disinfection and abrasion methods are unlikely to fully eradicate their presence. As pathogens enter the concrete structure, excess moisture within the body of the concrete feeds the pathogen for continued growth. Water leaching in from the surrounding environment and permeation at the surface from spills gets trapped in the concrete composite through the pores within the body.

Polished concrete floors

To combat the issues associated with the permeation of concrete floors and excess moisture, current industry trends are seeing more installation of polished or sealed concrete floors. Industry statistics state 15 to 20 percent of floors installed are polished concrete.6 However, these alternatives are extremely susceptible to cracking and softening. Polishing concrete floors does create a luster to a shined finish, but also imparts cracks led from the concrete surface to the body of the concrete. Cleaning agents seep into the cracks and cause further degradation into the body of the concrete. Knicks, gouges, and scratches to concrete sealer causes a singularity effect. This means the bacteria on the surface of the sealer has the tendency to migrate toward the damaged spot and leach onto the concrete surface and into the concrete.

Concrete should be used as a substrate and not as a floor coating, as it absorbs bacteria within any cracks or through spills. Even with the use of disinfectants or cleaning agents, polished concrete floor is prone to further damage.

Pathogen growth

The harmful microbes reproduce rapidly at an exponential rate under favorable conditions. Factors such as oxygen, pH, temperature, and light influence microbial growth.7 Additional factors include osmotic pressure, atmospheric pressure, and moisture availability.8 In restaurants, schools, hospitals, and stores, contaminants are transmitted through touchpoints. Studies have found 40 percent of E. coli and similar bacteria strains are transferred from surfaces to fingertips when touched.9

The meat, dairy, and produce departments of stores are teaming with bacteria due to foodborne illnesses. These areas are specifically susceptible because of the large equipment which makes floor cleaning difficult. Extreme disinfection is required to kill pathogens, and this is not possible in all areas due to physical blockades.

Vinyl flooring

Vinyl flooring has been around for more than 100 years, invented initially to replace linoleum. In the 1940s, vinyl flooring became very popular for areas where resilience, durability, and water-resistance was important.10 Vinyl composite tile is a mixture of natural pulverized limestone, filler materials, thermoplastic binders, and color pigments. Vinyl is less porous than concrete

and subsequently less permeable. This reduces the capacity for the surface to absorb and store pathogens or the nutrients feeding these pathogens. Most importantly, this allows for more effective cleaning during daily operations.

Vinyl flooring minimizes pathogen growth at the surface and reduces penetration of these pathogens throughout the entire body of the concrete.11 This is due to the hydrophobicity, or ability to repel water, of the vinyl flooring. These anti-adhesive surfaces are used to protect the porous concrete and impede microbial attachment to the surface. Not only does vinyl protect humans from harmful pathogens, but it also protects businesses, schools, and hospitals from constant maintenance and flooring replacement.

[3]

[3]Conclusion

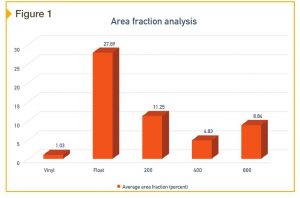

To maintain human safety in stores and hospitals, it is imperative to minimize pathogen spread and growth. This is done by utilizing flooring with minimal permeability. Vinyl flooring is less permeable and, therefore, optimally prevents pathogens from saturating through the body of the material. This has been shown through the absorption of moisture through the body of the sample, as well as the pathogen growth found at the surface. Therefore, it was found vinyl flooring systems are more resistant to pathogen growth, spread, and contamination to customers and employees, creating a safer and more profitable shopping experience (Figure 1).12

Notes

1 Lemmen, S., Hafner, H. Z., & Lutticken, R. (2004). Distribution of multi-resistant Gram-negative versus Gram-positive bacteria in the hospital inanimate environment. Journal of Hospital Infection, 191-197.

2 Roos, R. (2010, May 24). USDA estimates E coli, Salmonella costs at $3.1 billion. Retrieved from Center for Infectious Disease Research and Policy: www.cidrap.umn.edu/news-perspective/2010/05/usda-estimates-e-coli-salmonella-costs-31-billion.

3 See note 2.

4 Gaille, B. (2018, October 6). Small Business and Marketing Advice. Retrieved from 27 Retail Grocery Industry Statistics, Trends & Analysis: brandongaille.com/27-retail-grocery-industry-statistics-trends analysis/#:~:text=There%20are%20more%20than%2038%2C000%20grocery%20stores%20and,industry%20is%20just%201.1%25.%20%28Food%20Marketing%20Institute%29%20%235.

5 USDA Economic Research Service. (1996). Bacterial Foodborne Disease—Medical Costs and Productivity Losses. AER-741.

6 Read more about polished concrete here, www.concretedecor.net/departments/grinding-polishing/polished-concrete-continues-to-gain-momentum-as-flooring-choice.

7 Bailey, R. (2018, September 19). Phases of the Bacterial Growth Curve. Retrieved from ThoughtCo.: www.thoughtco.com/bacterial-growth-curve-phases-4172692.

8 See note 7.

9 Rusin, P., Maxwell, S., & Gerba, C. (2002). Comparative surface‐to‐hand and fingertip‐to‐mouth transfer efficiency of gram‐positive bacteria, gram‐negative bacteria, and phage. Journal of Applied Microbiology.

10 Lewitin, J. (20, November 09). Types of Vinyl Flooring Materials: Tile, Sheet Vinyl, and Luxury Vinyl. Retrieved from the spruce: www.thespruce.com/vinyl-flooring-materials-1314764.

11 Westbrook, M. A., & Belkowitz, J. S. (2020). An Analysis of Pathogen Growth on Vinyl and Polished Concrete.

12 Data retrieved from “An Analysis of Pathogen Growth on Vinyl and Polished Concrete.

References

- American Concrete Institute. (n.d.). The relationship between porosity and permeability of concrete. Retrieved from Technical Questions: concrete.org/tools/frequentlyaskedquestions.aspx?faqid=661.

- Bennion, J. e. (2008). Decreasing Listeriosis Mortality in the United States, 1990-2005. Clinical Infectious Diseases, 867-74.

- CDC. (2013). Multistate Outbreak of Multidrug-Resistant Salmonella Heidelberg Infections Linked to Foster Farms Brand Chicken (Final Update). Retrieved from CDC: www.cdc.gov/salmonella/enteritidis-08-20/index.html[4].

- CDC. (2020). Outbreak of Salmonella Enteritidis Infections Linked to Peaches. Retrieved from CDC: www.cdc.gov/salmonella/enteritidis-08-20/index.html[4].

- Council for Agriculture, Science and Technology (CAST). (1994). Foodborne Pathogens: Risks and Consequences: Task Force Report

No.122. 1-87. - USDA Economic Research Service. (1996). Bacterial Foodborne Disease—Medical Costs and Productivity Losses. AER-741.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG39_Photo-Nov-04-6-37-48-PM.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG39_Photo-Nov-04-6-38-42-PM-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/graphconcretearticle.jpg

- www.cdc.gov/salmonella/enteritidis-08-20/index.html: https://www.cdc.gov/salmonella/enteritidis-08-20/index.html

Source URL: https://www.constructionspecifier.com/analyzing-bacterial-growth-on-vinyl-and-polished-concrete/

Mallory Westbrook graduated from Georgia Institute of Technology with a bachelors of science in biomedical engineering. Westbrook began working with Intelligent Concrete, LLC in 2017 and specializes in research on nanotechnology for concrete strength and durability. Westbrook has published several articles relating to concrete science and technical transfer.

Mallory Westbrook graduated from Georgia Institute of Technology with a bachelors of science in biomedical engineering. Westbrook began working with Intelligent Concrete, LLC in 2017 and specializes in research on nanotechnology for concrete strength and durability. Westbrook has published several articles relating to concrete science and technical transfer. Jon Belkowitz, PhD, PE, is the chief technical officer at Intelligent Concrete, LLC, specializing in concrete research, development, and education with a focus on nanotechnology. Before Intelligent Concrete, LLC, he served in the United States Air Force (USAF) from 1996 to 2006, specializing in civil engineering. Belkowitz has worked in private testing laboratories on structural engineering and materials development projects to include the application of nanotechnology in concrete. He has worked as a consultant on projects in the United States, India, Turkey, Africa, Italy, New Zealand, Australia, and Germany. He has worked as chief of materials for a

Jon Belkowitz, PhD, PE, is the chief technical officer at Intelligent Concrete, LLC, specializing in concrete research, development, and education with a focus on nanotechnology. Before Intelligent Concrete, LLC, he served in the United States Air Force (USAF) from 1996 to 2006, specializing in civil engineering. Belkowitz has worked in private testing laboratories on structural engineering and materials development projects to include the application of nanotechnology in concrete. He has worked as a consultant on projects in the United States, India, Turkey, Africa, Italy, New Zealand, Australia, and Germany. He has worked as chief of materials for a