Thermal control plan

A TCP is a document typically prepared by an experienced licensed engineer who is knowledgeable on the thermal behavior of concrete. A TCP provides a foundation to ensure high thermal stresses and cracking of mass concrete will be avoided, and that its long-term durability will not be negatively affected. This is attained through the control of both the maximum temperature in the concrete (at the core or center of mass) and the temperature differential between the core and the outside faces of the concrete elements. It is an action plan for the contractor that includes information on mix design optimization, concrete cooling options, allowed concrete temperatures at point of placement, expected temperature rise, requirements for form insulation, anticipated duration of the thermal control period, requirements of number and location of the concrete temperature sensors, and more.

Historically, most specifications and TCPs follow ACI 301 with respect to the temperature restrictions. In many cases, a thorough analysis of the design and the corresponding mix constituents allows the engineer to offer less restrictive requirements, especially when it comes to the temperature differential.

The purpose of limiting the temperature differential within the element is to avoid thermal cracking that can result from a large temperature difference between the center and exterior surfaces. Temperature differentials lead to internal stresses, and if the concrete (especially in the first few days of curing) is not able to resist the temperature-induced stresses, cracking will result. The cracking can result in long-term structural and durability issues.

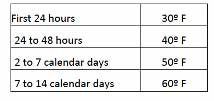

ACI’s limit of 19.4 C (35 F) is safe, conservative, and simple to implement, which is why this limit has typically been the standard for most projects. However, the main shortcoming of this restriction is that it does not account for the strength the concrete gains while it cures. Having recognized this shortcoming, numerous agencies and institutions have implemented a temperature differential approach that is based on time. This method is typically referred to as a stepped temperature differential limit.

Figures 2 and 3 appear to be switched around. Figure 2 shows a flat set temp and is labelled the PBDTL method whereas Figure 3 shows a sloping variable differential temp and is labelled the conventional temp set method. Please verify.

Opinions are my own, not my employer’s.