Although the stepped approach is an improvement compared to the set limit, the specifications are making assumptions on the concrete’s strength as it cures. Thankfully, there is another method: the performance-based temperature differential limit (PBTDL).

Performance-based temperature differential limit

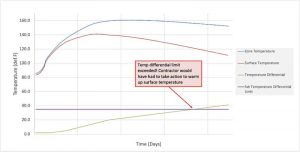

The PBTDL method provides a temperature differential limit that is directly tied to the concrete’s compressive strength. It completely replaces the 19.4 C (35 F) temperature differential limit. Essentially, the allowed temperature differential will increase as the concrete gains strength. Initial testing on the mix is required to determine material properties, such as elastic modulus, tensile strength, and the coefficient of thermal expansion. These properties are used to develop a chart that provides the temperature differences the concrete can resist without resulting in thermal cracking.

The strength of in-place concrete is determined through the maturity method, which is an ASTM standard that correlates the temperature history to strength. This means, if the temperature of the concrete is being tracked while it is curing, the maturity method can accurately determine the real time in-place strength.

The development of a performance-based TCP may require additional pre-planning compared to a traditional plan. However, the cost savings in the field far outweigh any of the additional engineering costs. Figure 2 shows an example of a typical concrete temperature curve. For both the core and the surface, the temperatures typically climb and peak around the first two days, with the core temperature exceeding the surface temperature. The differential between the two will start to rapidly increase as the surface temperature starts to cool significantly faster than the core. It is common to see the temperature differential peak around the third or fourth day.

Figures 2 and 3 appear to be switched around. Figure 2 shows a flat set temp and is labelled the PBDTL method whereas Figure 3 shows a sloping variable differential temp and is labelled the conventional temp set method. Please verify.

Opinions are my own, not my employer’s.