At the intersection of fire safety and energy efficiency

Test procedure

The NFPA 285 test evaluates flame spread—vertically and horizontally—across the wall assembly, along with ensuring temperatures are not exceeded within specific areas.

The test involves construction of a two-story room, with the proposed wall assembly as the exterior wall. The lower room includes a window opening (non-glazed). To simulate a building fire, a gas burner is placed in the center of the lower room, and a second, portable gas burner is placed in the window opening. The two burners are ignited at specified intervals during the 30-minute test and must heat the first floor to defined temperatures by specified times.

Test results

The test results are expressed as either ‘pass’ or ‘fail.’ Either an insulation (or other product) is deemed to be NFPA 285-compliant in a given wall assembly, or it is not. NFPA 285 does not rate using degrees of performance, as is the case with some fire tests (such as those for fire-rated glazing that result in 30-, 60-, or 90-minute ratings).

To pass NFPA 285, at no time during the test can flames spread beyond defined horizontal and vertical limits outside the building—3 m (10 ft) above the top of the window opening and 1.5 m (5 ft) horizontally from the window centerline. Additionally, no flame propagation is allowed into the second-floor room, and the temperature at five thermocouples placed 3 m (10 ft) above the window cannot rise to greater than 538 C (1000 F).

Engineering analysis option

As NFPA 285 is an assembly test, building product manufacturers generally must test their materials within many different wall assemblies. To avoid the impracticality of testing every possible combination of materials in an assembly, engineering analysis may be permitted in accordance with IBC Section 104.11, “Alternative materials, design, and methods of construction and equipment.” Additionally, some code reports—such as those issued by International Code Council Evaluation Service (ICC-ES), applicable across all jurisdictions—specifically allow engineering analysis by independent laboratories to extend the NFPA 285 test results. Such analysis might include cone calorimeter flammability testing to determine if a proposed alternative material performs the same or better than a given NFPA 285-compliant product. (For additional discussion, see “NFPA 285: Engineering Extension of Tested Assemblies” at www.appliedbuildingtech.com/content/nfpa-285-engineering-extension-tested-assemblies.)

Using rigid-foam insulation

in NFPA 285-compliant assemblies

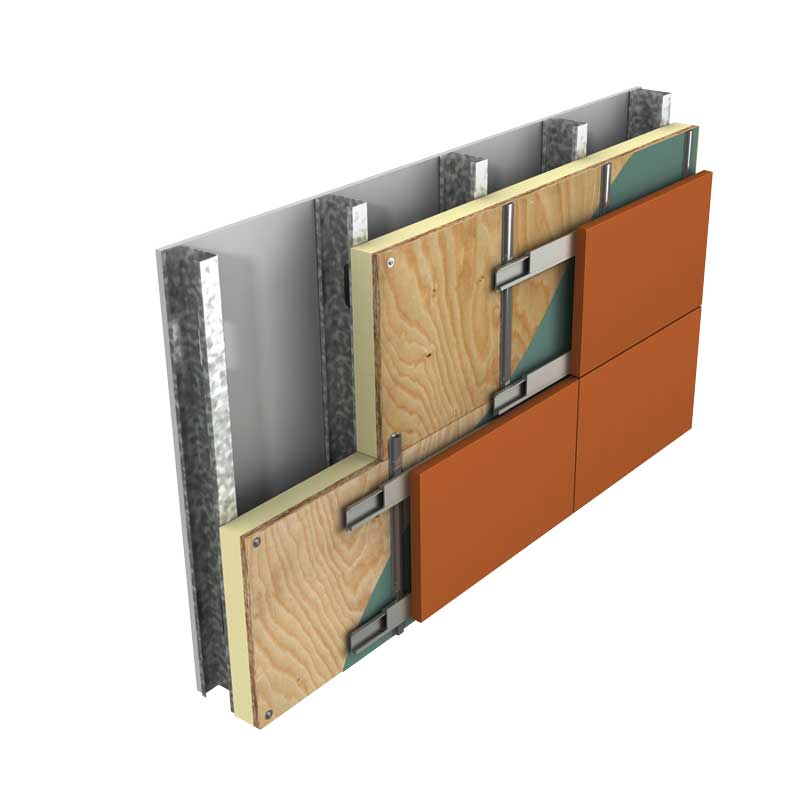

As rigid-foam insulations are combustible, they

must pass as components within NFPA 285-tested assemblies to be used as CI. The rigid foams commonly used in wall assemblies are:

- polyisocyanurate (polyiso);

- expanded polystyrene (EPS); and

- extruded polystyrene (XPS).

Each of these insulation types has been used in NFPA 285-compliant wall assemblies, although some are better-suited for certain types of assemblies than others. It is also important to remember even if a specific manufacturer’s polyiso, EPS, or XPS product has passed the test, it does not mean other manufacturers’ products of the same type have also passed.

Flame spread

Rigid foams behave differently from one another during a fire, as shown in testing under ASTM

E84, Standard Test Method for Surface Burning Characteristics of Building Materials. As the evaluated samples are mounted in the ceiling position, this test is not indicative of performance in wall assemblies, but as acknowledged in Section 1.2, “The purpose of this test method is to determine the relative burning behavior of the material by observing the flame spread along the specimen.”

Polyiso insulations are available in both Class A (flame spread <25) and Class B (flame spread <75), while most EPS and XPS products are Class A. EPS and XPS have ASTM E84 values <25 because they melt and no longer remain in the test position. (See “Fire Resistance Properties of Polyiso Foam Plastic Insulation Used in Wall Assemblies” at bit.ly/2oRzf4W.) This is acknowledged in ASTM E84 Section 1.4:

Testing of materials that melt, drip, or delaminate to such a degree that the continuity of the flame front is destroyed, results in low flame spread indices that do not relate directly to indices obtained by testing materials that remain in place.