Spandrel glass

Images courtesy Neumann Monson Architects

Full-coverage fritted glass, also known as spandrel glass, is non-see-through and is an effective bird collision deterrent. Available in hundreds of colors, it can conceal the building’s structural elements, while enhancing its design. It is manufactured by applying a thin layer of colored frit to the glass surface. The frit is essentially colored glass in the form of fine pulverized powder. Heating it in a tempering furnace to approximately 650 C (1200 F) melts and permanently fuses the color. It also transforms the glass into tempered safety material, meeting the requirements for ANSI Z97.1, For Safety Glazing Materials Used In Buildings – Safety Performance Specifications And Methods Of Test, and the Consumer Product Safety Commission (CPSC) standard 16 Code of Federal Regulations (CFR) 1201, Safety Standard For Architectural Glazing Materials.

New York City’s Liberty Park at the World Trade Center features white fritted glass in a decorative ventilated façade. The structure was designed by AECOM to dress up a vent for a below-ground parking garage.

Pattern-fritted glass

Available in multiple colors and virtually unlimited custom designs, pattern-fritted glass using the 2×4 rule is a bird collision deterrent. Among the chief benefits of this type of bird-friendly glass is the creative freedom it offers, as well as its large panel sizes, which are ideal for contemporary, expansive façade applications. A key aesthetic benefit is it can appear perfectly clear when viewed from afar, while still effectively preventing bird strikes.

Pattern-fritted glass is produced in the same way as full-coverage (spandrel) glass, with the addition of one critical step—a stenciled screen is applied in order to create the specified glass design. This technique is known as screen printing.

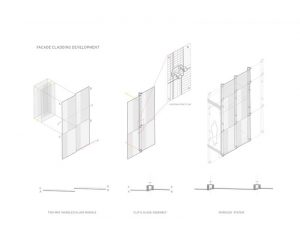

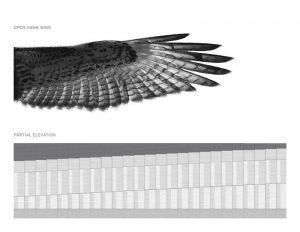

This technique was used to create the custom, hawk-wing inspired façade for the University of Iowa Kinnick Stadium expansion, designed by Neumann Monson Architects. The glass panels reach over 1524 x 3810 mm (60 x 150 in.) in size. They feature a variety of custom linear designs and sizes, as well as several custom shapes, to convey the architects’ vision. Extra-large print screens were produced to create the custom fritted design. Each glass panel was then carefully aligned to one of the screens to generate the mixed imprints. Thus, a diversity of patterns was made for the 1301 m2 (14,000 sf) of glass needed, minimizing costs by using just three screens.

Surface #1 fritted glass

At Johnson County Community College by BNIM, surface #1 pattern-fritted glass creates a white ventilated façade, filtering daylight into art studios and classrooms. The specified glass is a combination of a dot-pattern frit on the outside, laminated to full-coverage, light-diffusing etch on surface #4 (facing the interior of the building). The use of ultra-clear, low-iron glass and white frit on the outermost surface creates the exceptionally bright white aesthetic.

Surface #1 frit patterns designed to the 2×4 rule are among the most effective bird collision deterrents known to date. Placing the print on the outermost surface of the glass breaks up continuous reflections, making the pattern easily visible from various angles and under different light conditions. As an added benefit, façades such as this can also be used for projection, instantly transforming the building into a gigantic art display.

Digitally printed glass

Non-repetitive designs for bird-friendly glass applications can also be produced using a direct-to-glass printing technique. It uses pigments similar to the frits used in screen printing, but each color is applied to the glass akin to a desktop printer, adding the ability to create multi-colored designs and photo-realistic glass murals. Once the design is imprinted onto the glass, it is tempered to set the colors.

Unlike screen printing, which can be applied to any of the glass surfaces, direct-to-glass imprints are recommended on the #2 or #3 surface of the glass, away from direct exposure to the elements. They are usually protected by another piece of glass added through lamination or an insulated glass unit (IGU). Lamination is the process of permanently bonding two or more glass lites with a flexible or structural (rigid) interlayer, under the combined forces of heat and pressure. The interlayer prevents the pass-through of objects in the event of glass breakage and makes the glass safe, meeting the requirements for ANSI Z97.1 and 16 CFR 1201. Structural interlayers also add strength to the glass, allowing it to span greater heights under the imposed wind loads.

Another method to achieve the same or similar aesthetic is imprinting an interlayer and laminating it between two lites of clear glass.

Among the few limitations of digitally printed bird-friendly glass is its higher cost and slower fabrication, due to the time it takes to imprint each glass lite. However, it is the most appropriate solution for façades featuring varied designs.

Other types of bird-friendly glass

Etched glass is one of the most reliable and time-tested ways to make a glass façade bird-friendly and aesthetically pleasing at the same time. Similar to fritted glass, etched glass can be full-coverage or patterned, and is most effective when the etching appears on the #1 (outermost) surface of the glass. It is produced by exposing the glass to hydrofluoric acid, creating its characteristic frosted appearance and satin-smooth, maintenance-friendly finish. Sustainably produced acid-etched glass incorporates recycling the acid, and then neutralizing it for safe disposal.

Architects and designers can select from a wide variety of existing patterns and designs conforming to the bird-smart 2×4 rule, or design their own. Custom etched patterns can be costlier than custom printed and custom fritted designs, due to the price of the screens and minimum order requirements.

Another method to create the frosted aesthetic is sandblasting, which is bombarding the surface of the glass with sand or other particles. The disadvantage of this technique is a slightly rougher glass surface that is more prone to trapping dirt. The more maintenance-friendly method to create simulated etched glass is through fritting, using a translucent frit that mimics the frosted look.

Ultraviolet (UV)-pattern glass is among the newest method to apply patterns to the material, and was developed specifically for bird-friendly glass applications. A UV-reflective coating is used to create 2×4 bird-safe patterns, which are mostly invisible to humans, but easily perceived by those bird species able to see light in the UV spectrum. UV-pattern glass is currently available from a single provider, and its manufacturing process is proprietary. The chief limitation of this type of bird-friendly glass is its cost.