Photo © www.bigstockphoto.com

by Brad Douglas, PE

American Wood Council (AWC) regularly reviews and updates its codes and standards to keep pace with technological advances and material innovations affecting the use of wood products in the country. By ensuring the provisions of these documents accurately reflect current U.S. safety and performance requirements, and by providing education so that the standards are properly implemented, AWC is helping keep buildings safe. The council recently updated its National Design Specification (NDS) for Wood Construction. Developed by AWC’s wood design standards committee, the 2018 NDS is referenced for wood design in this year’s International Building Code (IBC). It has been approved as an American national standard by the American National Standards Institute (ANSI). The 2018 NDS has significant additions to address increased wind loads in American Society of Civil Engineers (ASCE) 7-16, Minimum Design Loads and Associated Criteria for Buildings and Other Structures.

All graphics courtesy American Wood Council

Changes in the 2018 NDS include:

- allowance for specific patterns and lumber sizes when obtained from the company providing the incising;

- inclusion of a volume factor (Cv) for structural composite lumber (SCL) tension parallel to grain values;

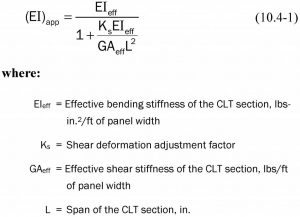

- inclusion of effective shear stiffness for cross-laminated timber (CLT);

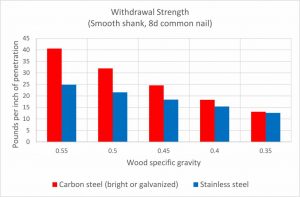

- added equation for withdrawal design values for smooth shank stainless steel nails;

- new provisions for new roof sheathing ring shank (RSRS) nails in accordance with ASTM F 1667, Standard Specification for Driven Fasteners: Nails, Spikes, and Staples;

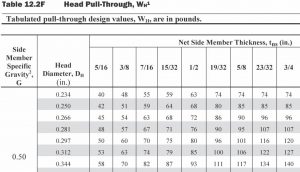

- new design provisions for fastener head pull-through of fasteners with round heads;

- revision to method for calculation of lateral design values for threaded nails to be based on use of shank diameter instead of root diameter in accordance with changes in ASTM F 1575, Standard Test Method for Determining Bending Yield Moment of Nails;

- revised timber rivet design value tables to limit maximum distance perpendicular to grain between outermost rows of fasteners; and

- revised terminology for fire design of wood members to clarify the difference between ‘char depth’ and ‘effective char depth,’ employed in structural calculations. Provisions for connections are also revised to more precisely describe the requirements for protection of the connection from fire exposure.

Structural composite lumber

NDS Chapter 8 on SCL was revised to include a volume factor for tension parallel to grain design values (Ft). A change was also made to clarify dry service conditions are associated with situations in which the moisture content of sawn lumber is less than 16 percent, as in most covered structures. These changes correlate with ASTM D 5456, Standard Specification for Evaluation of Structural Composite Lumber Products.

Cross-laminated timber

Revisions were made to CLT deflection provisions to include the term GAeff (effective shear stiffness of the CLT section). This change correlates with ANSI/APA−The Engineered Wood Association (APA) Performance-rated Glulam (PRG) 320-2017, Standard for Performance-rated Cross-laminated Timber, to facilitate the calculation of apparent bending stiffness (EI)app consistent with properties as provided in PRG 320 (Figure 1).

Fastener design

Revision of NDS connection design provisions were primarily in response to significant increases in components and cladding roof wind pressures in ASCE 7-16. Primary changes include added equation for stainless steel nail withdrawal strength.

Stainless steel nails have lower withdrawal strength compared to carbon steel wire nails of the same diameter because of the reduced surface friction of stainless steel. The differences in withdrawal strength vary with the specific gravity of wood. When stainless steel nails are specified as an alternative to reference smooth shank carbon steel wire (bright or galvanized) nails in wood construction, including shear walls and diaphragms, these differences in withdrawal strength must be considered. For example, where smooth shank stainless steel nails are employed for roof sheathing attachment, more nails, or nails of greater strength or diameter, may be required to provide equivalent withdrawal strength performance for wind uplift.

NDS has added design provisions for RSRS nails, which have higher withdrawal design values than smooth shank nails. Recently added to ASTM F 1667, RSRS nails provide additional options for efficient attachment of wood structural panel sheathing. In many cases, specification of RSRS nails produces a reduced roof sheathing attachment schedule than permissible by use of smooth shank nails, and enables the use of a single minimum fastener schedule for roof perimeter edge zones and interior zones.

The NDS also has new fastener head pull-through provisions. Fastener head pull-through data—used to set industry recommendations for wood structural panels—combined with historical data from tests of lumber and plywood was analyzed to develop new provisions. Within the range of head diameters, thicknesses, and specific gravities in NDS, the analysis found head pull-through is related to the perimeter of the fastener head. For the design of roof sheathing fastening to resist wind uplift, the addition of head pull-through allows the controlling roof sheathing fastener spacing to be calculated from the lesser of the head pull-through design value or the fastener withdrawal design value from wood in accordance with NDS. Previously, such design required a combination of design documents including minimum prescribed spacing criteria for wood panels.

Provisions for specifying diameter for threaded nails have been revised in the latest edition of NDS. A change in ASTM F 1575 clarifies nail bending yield strength (Fyb) is based on the nominal diameter (D), and not on the root diameter (Dr). This change simplifies the calculation of nail moment resistance in NDS yield equations for nails specified in ASTM F 1667 because D is provided for all nail types, and Dr is not always provided for deformed shank nails. As a result, the revised NDS provisions allow the use of D for deformed shank nails per ASTM F 1667 when calculating lateral design values in accordance with the yield limit equations.

Fire design of wood members

NDS Chapter 16 on fire design of wood members was revised to provide separate calculations of char depth based on nominal char rates for wood (achar), and effective char depth for use in structural calculations, (aeff). Increased use of wood as a fire-protective covering has made it important to provide provisions for calculation of the expected achar separate from aeff. Previous versions of NDS have only provided aeff, which is increased 20 percent over achar to account for loss of strength and stiffness because of elevated temperatures in uncharred wood near the char front.

NDS Supplement

Additionally, NDS Supplement design values remain unchanged with only a few exceptions. New and revised grades of machine stress-rated and machine-evaluated lumber have been added. Redwood grades requiring ‘close grain’ were removed due to general lack of availability for commercial use. Other revisions include the addition of Norway spruce from Norway to foreign species dimension lumber, and the addition of shear-free moduli of elasticity for structural glued-laminated (glulam) softwood timber.

To make this code-referenced standard as user-friendly as possible, AWC will also be developing supporting publications, such as an NDS Commentary, revising technical reports and design aids, and conducting further research to ensure continued widespread acceptance of wood in construction.

The updated NDS and 2018 NDS Supplement: Design Values for Wood Construction are currently available online. The NDS Commentary and other support documents will soon be available.

The 2018 NDS represents state-of-the-art for design of wood members and connections, demonstrating how timber products can safely and efficiently meet or exceed U.S. requirements.

Brad Douglas, PE, is vice-president of engineering at the American Wood Council (AWC), which represents the interests of the North American wood products industry. Douglas directs a program aimed at developing state-of-the-art engineering data, technology, and standards on structural wood products, systems, and assemblies for use by design professionals and building officials to assure safe and efficient design and use of wood. He is a graduate of Virginia Tech. Douglas can be contacted at bdouglas@awc.org.

Brad Douglas, PE, is vice-president of engineering at the American Wood Council (AWC), which represents the interests of the North American wood products industry. Douglas directs a program aimed at developing state-of-the-art engineering data, technology, and standards on structural wood products, systems, and assemblies for use by design professionals and building officials to assure safe and efficient design and use of wood. He is a graduate of Virginia Tech. Douglas can be contacted at bdouglas@awc.org.