Attaining an effective flow-through assembly

To achieve an effective flow-through assembly, a system to reduce the vapor flow rate from the interior is required (when there is a lack of ci on the outside).

Additionally, for all flow-through assemblies, a ventilated cladding system is needed to cover the ci or exterior sheathing to let the passing moisture get around the wall assembly. Most claddings do not need a significant amount of space. Joe Lstiburek recommends a minimum of 9.5 mm (3/8 in.).

However, when it comes to reservoir claddings, such as brick veneers, and very vapor-open sheathings (coupled with very vapor-open water and air control layers), a larger space is needed. For brick, 25 mm (1 in.) is recommended. For stucco, the recommendation is to use paint coupled with an engineered ventilated rainscreen layer and the 9.5-mm space.

The larger gap and paint are needed for stucco because vapor can flow both in and outward.

Photo courtesy Boulder Wildland Fire Station

The inward motion (known as solar-driven moisture) occurs with a rain-wetted reservoir cladding, coupled with solar radiation and air-conditioning. This inward motion should be ‘throttled’ down and the cladding should be uncoupled with a ventilated air space, or the size of the reservoir has to be reduced by painting the cladding or by using additives with the ability to reduce water absorption.

Figure 2 illustrates the various configurations of flow-through assemblies, whereby the ‘base’ assembly is limited to IECC climate zones 5 and lower (unless an interior vapor throttle such as a smart vapor barrier is used).

Not all membranes are moisture vapor permeable

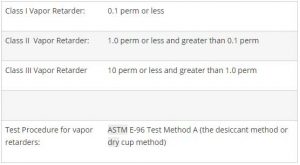

Vapor retarders can assist with vapor management, as they are designed and installed in an assembly for the purpose of impeding the movement of water by vapor diffusion. These fall under Class I vapor retarders (Figure 3). Clearly, not all membranes are designed to be moisture vapor permeable. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Journal, a membrane must have a permeance greater than 5 perms to be classified as permeable.

The following are some key considerations to achieve vapor permeability when designing a well-performing wall assembly:

- use a water-resistive barrier (WRB) to keep bulk water out of the wall;

- employ an air barrier to prevent air movement through the wall (which could otherwise cause condensation); and

- use a vapor retarder appropriate for the particular type of wall and climate zone.

Photo courtesy Hotel Lismore

High-performance air and moisture barriers

Vapor barriers can be placed on the warm side of the insulation without being sealed airtight, as long as there is an uninterrupted air barrier somewhere else in the wall and ceiling assemblies. The reason for this is simple: diffusion of moisture vapor is slow, while moving air carries moisture vapor faster. Multiple materials to achieve this are not always necessary, especially as some products provide a combination of these qualities already. The key here would be to find a high-performance air and moisture barrier resistant to air movement, and in turn, resistant to the moisture vapor carried by the moving air as a result of increased airtightness. As discussed, though some projects will call for the use of individual barriers and membranes, for an airtight and moisture-controlled building one need not always have a combination of materials. According to John Straube, vapor barriers primarily control the diffusion, used only when needed, and are only placed near the warm side of a wall. Air barriers, on the other hand, control air flow and can be placed anywhere. Fortunately, there are products incorporating all these qualities. For example, fully adhered polymeric spun-bonded membranes are multifunctional and provide high moisture permeability along with the all-important water- and air-tightness.

Conclusion

Making a building as airtight as possible is an important first step when determining what barriers to use. The more airtight the building, the fewer vapor issues will arise and the less critical a vapor barrier will be. Having said that, airflow is not the sole cause of vapor issues, so while an air barrier is a must, a vapor barrier can still significantly benefit a building.

Most of the confusion in building envelope functionality is caused by manufacturers who mislead and blur the line between their products and its supposed function. It’s ironic when this happens on Construction Specifier, but this is still rampant on most “building science” sources.

I’ve found the most helpful distinction is 5 specific barriers:

1. Bulk water (rain, sprinklers)

2. Moisture (wind blown droplets, condensation)

3. Air (dry)

4. Humidity (the moisture in air)

5. Thermal (temperature)

Yes, some products serve multiple purposes, but I have seen Moisture and Air confused more often then described correctly. For example, any product that absorbs moisture within the time it takes for typical exterior envelope drying (3-5 days of dry weather) is actually not a barrier to moisture.

Peter – Very nice article.

Wagdy Anis (RIP) – would refer to an air barrier as an Air and Water barrier or in the day – sheet rubberized asphaltic or butyl barrier (SRAB/SRBB), and a vapor barrier not as a barrier at all, rather a retarder. “there can be thousands of holes in a vapor retarder assembly in a building enclosure, and the retarder would work effectively. It is not necessary for a vapor retarder assembly to be installed/sealed air tight”.

I continue to believe that Wagdy had it right, in using the term retarder for vapor control assemblies. Delineating building enclosure key components as retarders and barriers provides clarity for the building enclosure designer, notwithstanding IECC continues to use both terms.