Back to basics: Differences between air and vapor barriers

by sadia_badhon | August 6, 2019 10:05 am

by Peter Barrett

[1]

[1]It has been said before, but bears repeating: as much as 80 percent of premature building wear expenses are related to moisture[2] in one way or another. Water is the most significant factor in the premature deterioration of buildings, as it can cause corrosion of metals, rotting and mold in organic substances, dissolution of materials, reduction in effectiveness of insulation,

and more.

Building industry professionals largely agree on the importance of moisture control methods, but there is frequent confusion about the use of vapor and air barriers[3]. To make the right decision on which methods and materials to include in a building envelope, it is critical to understand the simple, yet significant, differences between air and vapor barriers, and their role as part of an effective system.

Air barrier function

[4]

[4]Images © Joe Lstiburek

An air barrier’s function is primarily to stop air leakage and resist differences in air pressure by keeping the indoor climate regulated. Simply put, air barriers keep the outdoor air out and the indoor air in. An air barrier should be:

- durable enough to withstand construction pressures and handling;

- impermeable to airflow; and

- continuous, enclosing, or enveloping the entire conditioned space.

While air barriers are key to limiting the airflow in and out of a living space, it is important to note air from either a conditioned or an unconditioned side may still find its way into walls. So, even though it is critical for a living space to have walls that are as airtight as possible, the assembly of the wall itself should always be moisture vapor permeable to allow for incidental moisture to escape, or diffuse, rather than be trapped and make the structural materials of the wall wet.

A vapor barrier’s most important function, on the other hand, is to be impermeable to moisture in vapor form, thereby preventing the movement of water vapor through the wall cavity from going outside, and vice versa. While this notion sounds simple, it is not.

Effects of rainwater penetration through walls

[5]

[5]One of the trickiest elements coming into the wall from the outside is rainwater (also known as bulk water), which almost always causes trouble. Most significant would be the issues caused by water moving inward and reaching the vapor barrier where it gets trapped, causing catastrophic failure of the wall in the form of rot and mold. One feasible solution is to eliminate the vapor barrier altogether, allowing the wall to dry from both sides, thereby creating a flow-through assembly. While it may be possible in many cases, the elimination of the vapor barrier is not always an option.

Leaving out the vapor control layer is only possible in structures with non-extreme environmental loads and continuous insulation (ci) on the outside. As noted by building industry educator Joe Lstiburek[6], a non-extreme environmental load essentially means a building enclosure on an office, house, or apartment as opposed to the façade of a natatorium, museum, hospital, or art gallery. The enclosures subjected to an extreme environmental load are operated at high interior humidity (50 percent or higher year round) and are pressurized. Therefore, for natatoriums, museums, hospitals, or art galleries, a wall incorporating a vapor barrier layer to the interior is essential to maintain moisture vapor impermeability.

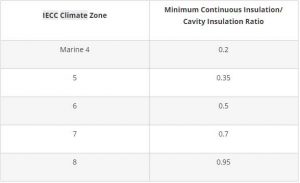

Some restrictions come into play for non-extreme environmental loads without ci on the outside. In colder climates, some kinds of interior ‘vapor throttles’ are required. A vapor throttle is essentially the component with the lowest moisture vapor permeability compared to the rest of the elements of the wall. This component tends to establish the overall moisture vapor permeability of the wall system. The International Energy Conservation Code (IECC) specifies climate zones 6 and higher as requiring a vapor control layer (Figure 1). In these cases, a ‘smart’ vapor barrier (a material whose moisture vapor permeability increases when relative humidity [RH] is high and decreases when RH is low), which works without the need for ci in such climate zones (6 or higher), can be used as well.

Attaining an effective flow-through assembly

[7]

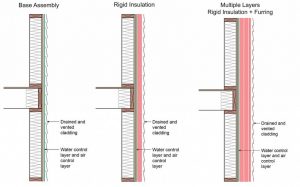

[7]To achieve an effective flow-through assembly, a system to reduce the vapor flow rate from the interior is required (when there is a lack of ci on the outside).

Additionally, for all flow-through assemblies, a ventilated cladding system is needed to cover the ci or exterior sheathing to let the passing moisture get around the wall assembly. Most claddings do not need a significant amount of space. Joe Lstiburek[8] recommends a minimum of 9.5 mm (3/8 in.).

However, when it comes to reservoir claddings, such as brick veneers, and very vapor-open sheathings (coupled with very vapor-open water and air control layers), a larger space is needed. For brick, 25 mm (1 in.) is recommended. For stucco, the recommendation is to use paint coupled with an engineered ventilated rainscreen layer and the 9.5-mm space.

The larger gap and paint are needed for stucco because vapor can flow both in and outward.

[9]

[9]Photo courtesy Boulder Wildland Fire Station

The inward motion (known as solar-driven moisture) occurs with a rain-wetted reservoir cladding, coupled with solar radiation and air-conditioning. This inward motion should be ‘throttled’ down and the cladding should be uncoupled with a ventilated air space, or the size of the reservoir has to be reduced by painting the cladding or by using additives with the ability to reduce water absorption.

Figure 2 illustrates the various configurations of flow-through assemblies, whereby the ‘base’ assembly is limited to IECC climate zones 5 and lower (unless an interior vapor throttle such as a smart vapor barrier is used).

Not all membranes are moisture vapor permeable

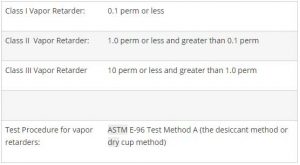

Vapor retarders can assist with vapor management, as they are designed and installed in an assembly for the purpose of impeding the movement of water by vapor diffusion. These fall under Class I vapor retarders (Figure 3). Clearly, not all membranes are designed to be moisture vapor permeable. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Journal, a membrane must have a permeance greater than 5 perms to be classified as permeable[10].

The following are some key considerations to achieve vapor permeability when designing a well-performing wall assembly:

- use a water-resistive barrier (WRB) to keep bulk water out of the wall;

- employ an air barrier to prevent air movement through the wall (which could otherwise cause condensation); and

- use a vapor retarder appropriate for the particular type of wall and climate zone.

[11]

[11]Photo courtesy Hotel Lismore

High-performance air and moisture barriers

Vapor barriers can be placed on the warm side of the insulation without being sealed airtight, as long as there is an uninterrupted air barrier somewhere else in the wall and ceiling assemblies. The reason for this is simple: diffusion of moisture vapor is slow, while moving air carries moisture vapor faster. Multiple materials to achieve this are not always necessary, especially as some products provide a combination of these qualities already. The key here would be to find a high-performance air and moisture barrier resistant to air movement, and in turn, resistant to the moisture vapor carried by the moving air as a result of increased airtightness. As discussed, though some projects will call for the use of individual barriers and membranes, for an airtight and moisture-controlled building one need not always have a combination of materials. According to John Straube, vapor barriers primarily control the diffusion, used only when needed, and are only placed near the warm side of a wall. Air barriers, on the other hand, control air flow[12] and can be placed anywhere. Fortunately, there are products incorporating all these qualities. For example, fully adhered polymeric spun-bonded membranes are multifunctional and provide high moisture permeability along with the all-important water- and air-tightness.

Conclusion

Making a building as airtight as possible is an important first step when determining what barriers to use. The more airtight the building, the fewer vapor issues will arise and the less critical a vapor barrier will be. Having said that, airflow is not the sole cause of vapor issues, so while an air barrier is a must, a vapor barrier can still significantly benefit a building.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2019/07/FILE-OPENER_Image-3_DELTA-VENT-SA_Audain-Art-Museum_Image-courtesy-Audain-Art-Museum.jpg

- related to moisture: https://www.ncbi.nlm.nih.gov/books/NBK143947/

- vapor and air barriers: http://buildingscience.com/documents/digests/bsd-106-understanding-vapor-barriers

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2019/07/Table-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2019/07/Figure-2_airvaporbarier.jpg

- Joe Lstiburek: http://buildingscience.com/documents/building-science-insights-newsletters/bsi-091-flow-through-assemblies

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2019/07/Table-2.jpg

- Joe Lstiburek: http://buildingscience.com/documents/insights/bsi086-vitruvius-does-veeners

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2019/07/Image-1-hi-res_Boulder-Wildland-Fire-Station_courtesy-of-Boulder-Wildland-Fire-Station.jpg

- permeable: http://buildingscience.com/documents/published-articles/pa-moisture-control-for-buildings/view

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2019/07/Image-2_2-DELTA-VENT-SA_Hotel-Lismore_courtesy-Hotel-Lismore.jpg

- control air flow: http://www.civil.uwaterloo.ca/beg/Downloads/Affordable-2005-Myths-%20Vapor.pdf

- pbarrett@dorken.com: mailto:pbarrett@dorken.com

Source URL: https://www.constructionspecifier.com/back-to-basics-differences-between-air-and-vapor-barriers/