The evidence

To better understand the claims, data, and prediction method in the ASHRAE handbook and AHRI standard, one should refer to ASHRAE RP-755. “It was initiated to investigate the transmission of sound through different ceiling types with the intent of providing more reliable design information to deal with sound transmission through ceilings close to HVAC devices.” The research was conducted by the National Research Council of Canada (NRC) for ASHRAE.

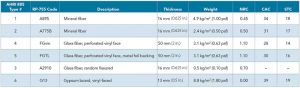

Within a large, acoustic chamber, the researchers tested a wide variety of ceiling panels including those made of fiberglass, mineral fiber, and gypsum board. At the time of the study, stone wool ceiling panels were not available in North America like they are now. Ceiling panel thicknesses varied from 13

to 50 mm (0.5 to 2 in.). Weights varied from 0.5 to 8.9 kg/m2 (0.1 to 1.8 psf). CAC ratings varied from 28 to 39. STC ratings varied from 16 to 19, while NRC ratings varied from 0 to 1.1 (refer to Table 1). These panels represent the full range of acoustic ceiling panels available in the market at the time of the study and still today.

The researchers used various types of mechanical equipment above the ceilings as the noise sources. These devices were installed as they would be in a building, having air moving through them, and conditioning the air. For each ceiling type, and each piece of mechanical equipment, the researchers measured the resulting noise levels in the room below at occupant ear height. They compared the known sound power levels of the mechanical equipment to the measured noise level at listener height to derive the attenuation being provided by each ceiling system.

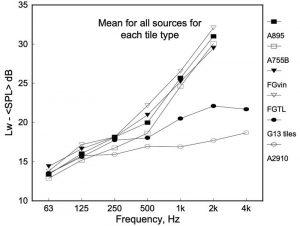

The study was empirical, using actual mechanical equipment operating as they would in buildings as the noise sources and actual ceiling systems installed as they would be in buildings. It was not theoretical or based on calculations, models, or simulations. Figure 2 shows the average attenuation by frequency octave band of each ceiling across all the different types of mechanical devices used in the study.

If the existing rule-of thumb were to hold true, one would expect the heaviest weight (8.9 kg/m2 [1.8 psf]) gypsum board panels (type G13) to provide the most attenuation. In fact, it performed second to worst. The rigid material spans the high points in the supporting grid flanges, leaving gaps elsewhere through which noise leaks. Additionally, the gypsum board provides no absorption in

the plenum or room. Even lower in attenuation performance is the very lightweight A2910 fiberglass panel. While it has the malleability to decrease leaks at the grid, it has low absorption (NRC 0.70) and very low weight (0.5 kg/m2 [0.1 psf]).

While stone wool ceiling panels were not offered in North America at the time of the study, their NRC rating, weight, and other attributes fall within the range of panels used in the study. Stone wool panels would perform similarly to the thick, fiberglass panels (AHRI types 4 and 5).

Stone wool and fiberglass ceiling panels have the right combination of all three factors for noise attenuation. They have high NRC, moderate weight, and malleable surfaces that are soft and seal the leaks at the grid. While there are slight differences in the attenuation provided by the different ceiling panel types, those differences are not significant enough to affect building occupant well-being over time.