Glazing systems

The guidelines refer to three common types of IGU glazing systems: structural glazing, butt glazing, and dry glazing.

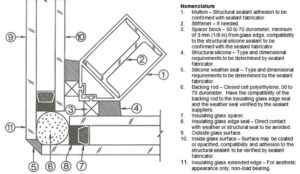

Structural glazing or stopless glazing, where the IGU is retained only by a silicone sealant or adhesive joint, requires special care as seal failure of a unit glazed without exterior stops could lead to the exterior lite falling from the building. The following factors should be considered in the design and installation of IGUs for stopless glazing.

- The adhesion characteristics of the silicone sealants should be tested with the corresponding spacers, corners, frame members, and glass with any applied coatings for each batch of the component materials.

- The compatibility of all components in contact with each other—including glazing sealants, IGU assembly sealants, setting blocks, gaskets, and joint backers—should be verified with component suppliers.

- Sealant selection should withstand long-term weathering effects including solar UV radiation, temperature extremes, and water exposure.

- Approximately 50 percent of the negative wind load on a unit is normally carried by the IGU sealants. If the IGU seal were to fail or an inner lite breakage were to occur, an increase of the negative load could be imposed on the IGU sealants.

- The IGU assembly sealant and structural silicone sealant should accommodate all movements of the structural frame and glass caused by wind, live and dead load deflection, and thermal expansion.

- Seals at the edges of the exterior glass components are weather seals and their width and elasticity need to ensure that excessive stresses are not transferred to the IGU. Setting blocks may have to be modified to suit the framing system but still be suitable for their intended function.

- Heat-strengthened glass should be used for the offset IGU at a corner condition.

Butt glazing or stopless glazing without a supporting mullion on any IGU edge is not recommended unless the glass is stiff enough to avoid the high shear stresses caused by wind loads on the unit sealant, potentially leading to seal failure. To determine whether this is relevant, consult the IGU fabricator.

Dry glazing is the common designation for the portion of the glazing system that uses a non-mastic compound as the seal between the glass and frame. Common dry glazing systems may use foam tapes or extruded rubber gaskets as the sealing material. The amount of compression and the type of sealing material determines reliability against possible water infiltration into the glazing cavity.

This is necessary as water ponding directly impacts the longevity of IGU seals. Consequently, weep systems should be employed to prevent water ponding in the glazing cavity. Compatibility of the dry glazing materials with IGU sealants should be confirmed through testing by the sealant manufacturer.

Gasket guidance

Dry glazing includes the following types: compression seals, structural gaskets (zipper or lock-strip gaskets), vinyl or marine wrap glazing, and foam tapes.

Compression seal gasket glazing systems use dense and/or sponge gaskets to achieve a compression seal. All major glazing components and materials—glass, gaskets, aluminum, wood, fiberglass, and vinyl—have tolerances. However, tolerances can accumulate and cause major problems such as glass not fitting and gaskets not sealing. To verify individual tolerances, check with the fabricators.

Another item for consideration, which may affect sealing ability, is the possibility of bowing, warping, and twisting of sash members. Molded and/or vulcanized corners are available in extruded gaskets. Molded corners reduce the possibility of water penetration at the corners, which is normally the weakest point in the system. If molded corners are not used, caulking may be required in the corners. Weep systems are essential with any compression glazing system.