BIM for Masonry: The bricks and mortar industry enters the digital age

Where BIM-M goes from here

Starting with the realization BIM is not a fad, but rather a new way of both designing and delivering construction services, the masonry industry remains coordinated and firmly behind the financial support of the project. In fact, this is the largest cooperative masonry industry effort ever undertaken.

There is a growing relationship with BIM Forum, integrating BIM-M with broader industry advancements, and the aforementioned Best Practices Guide. A roadmap posted online lists the many activities and final goals of the project, targeting December 2017 as the symbolic end of Generation 1 of the initiative.3 These goals include:

- masonry unit database accessible to all BIM users;

- masonry wall definitions for LOD 350 with standard details;

- software upgrades that achieve LOD 350 or greater for design;

- software that allows contractors to achieve LOD 400 or greater for construction purposes and can detect clashes with specific masonry features (e.g. bond beams, grouted cells, shelf angles, etc.);

- software upgrades that operate with other masonry-specific software;

- improved design tools (e.g. software upgrades, add-ins, plugs-ins) using Autodesk Revit that provide for modularity, early project pricing, and masonry detailing;

- improved contractor tools (e.g. software upgrades, apps for mobile devices, hardware-specific for field use) for contractors to improve project efficiency and utilize developing BIM tools; and

- beginning of development of new software specific to construction by third-party vendors.

Case study

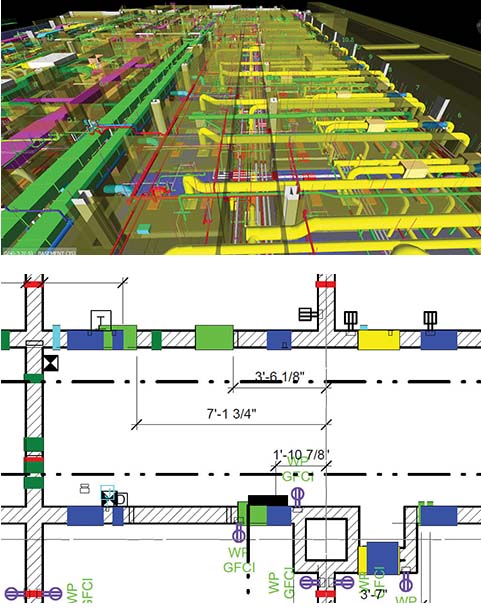

A recent healthcare research lab project in Chicago illustrates how building information modeling improves masonry trade coordination and helps

a project run more smoothly.4

The intricate construction of CMU walls laden with structural requirements and mechanical penetrations for this project was greatly aided through the use of BIM by providing the mason contractor advance input and notice of the various mechanical, electrical, and plumbing (MEP) requirements (Figure 2).