It is helpful to make a basic diagram of the fracture lines as viewed from the surface in a plan view (Figure 1). This can be easily done by examining the direction of the Wallner lines on the edges of individual pieces of glass. The origin of the break can be determined by:

- drawing arrows (indicating fracture line direction as viewed from the surface plan view) pointing toward the concave face of break wave markings in the glass edge; and

- tracing point-to-tail of arrows back to the break origin.

Failure modes

Knowing the origin of the break sets the stage for determining the mode, or type, of failure. The lack of crystallographic planes in glass can allow certain break patterns to be observed and then associated with modes of failure. Two common modes are mechanical and thermal.

Mechanical stress

The most common contributing factor of breakage, mechanical stress occurs when forces resulting from bending or impact exceed the modulus of rupture (MOR), a critical metric in stress analysis. There are low- and high-stress mechanical tension breaks.

Low-stress tension breaks are experienced most frequently by the manufacturers residential windows and IGUs. The origin of the break is typically at damaged areas of the edge or surfaces near the edge, such as digs, scratches, or chips. In many cases, in-service breakage of marred glass occurs after the initial edge damage is incurred, such as during IGU fabrication, sashing operations, transportation, jobsite handling or storage, or the installation process.

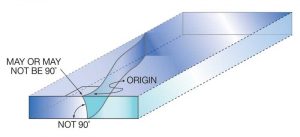

In Figure 2, the break origin is not 90 degrees to the edge of the glass, indicating a tension break caused by bending. Low-stress, mechanical tension breaks often occur from bending at less than 10,342 kPa (1500 psi).

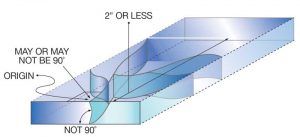

High-stress tension breaks share one characteristic with the low-stress ones—the break origin is not 90 degrees to the edge of the glass, suggesting a tension break caused by bending. However, additional branching of the crack within 50 mm (2 in.) of the break origin indicates the stress at breakage was likely higher than 10,342 kPa (Figure 3).

High-stress breakage due to impact at the glass edge or surfaces near the edge is typically the easiest to identify, as multiple fractures emanate from the point of impact in a spider web fashion (Figure 4). This breakage pattern is a tell-tale sign that either the glass edge or surface was struck by a foreign object with significant force.

Thermal stress

Thermal stress results from several factors including weather, the method of glass installation, and the insulation around the material. Breaks caused by thermal stress occur because of large temperature differences, most commonly between the edge and center of the glass. For instance, when the sun hits the glass and warms up its center, but the edges remain cold, the thermal gradient produces increased stress, potentially leading to breakage. This temperature gradient can be even more severe when glass is glazed into concrete and other heavier framing. These materials act as a heatsink keeping the edges cooler for a longer period of time. Thermal stress breaks often originate at the edge of the glass and form virtually 90-degree angles to the edge and surface of the glass.