Breaking it down: Keys to diagnosing glass breakage in buildings

In some situations, it is helpful to expand the investigation beyond determining the type of breakage and the stress level of the break. Pinpointing the actual source of the damage can help prevent or reduce future occurrences of breakage.

For example, a lite of glass might appear to have been broken by high, thermally induced stresses, when, in fact, a more-detailed analysis might reveal impact damage that reduced the thermal-loading threshold of the glass may have been the actual cause.

To identify what damaged the glass in the first place, four factors are examined during this analysis including:

- impact;

- inclusions;

- thermal variance; and

- pressure differentials.

Impact

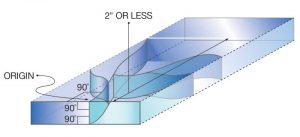

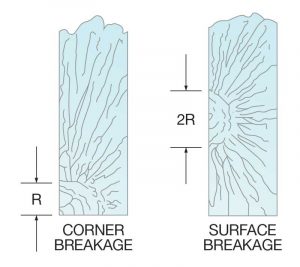

Identifying the nature of the breakage pattern can determine whether a foreign object hit the glass and if the impact was perpendicular or parallel.

Depending on the severity of the impact, the immediate area surrounding the break origin might be cracked, crushed, or missing (Figure 4).

Other sources of impact can be detected during the fabrication process or the transit and installation of the glass—these usually appear at the edges. As mentioned previously, edge damage can reduce the strength of the glass by more than 50 percent, thus increasing the likelihood of breakage due to mechanical and/or thermal stress.

Inclusions

Any undesirable material embedded in glass is considered an inclusion. Coming in numerous shapes and sizes, inclusions such as NiS and Al2O3 stones can have unlimited distribution densities. These densities factor into the glass quality ratings by ASTM C1036, Standard Specification for Flat Glass. Quality for clear glasses ranges from Q1 (used in the production of high-quality mirrors) to Q6 (applications in which blemishes are not a concern).

Contaminates in batch materials and furnace refractory degradation are often contributing factors of inclusions. Sometimes, however, an inclusion might consist of only unmelted batch material. Regardless of the source, responsible glass manufacturers go to great lengths to ensure inclusions are kept to a minimum. However, since the raw materials are mined from the earth, no known technology will totally eliminate the rare occurrence of nickel- or aluminum-related inclusions.

Effects of NiS inclusion

Similar to water, NiS increases in volume as it cools. The presence of NiS inclusion in the center residual tension stress region of thermally tempered glass can lead an investigator to believe the breakage occurred spontaneously. In reality, the breakage was likely caused by a phase transformation that increased (from two to four percent) the volume of the inclusion. This growth caused additional stresses, likely leading to the breakage.

Here is how this could happen. When float glass is manufactured, the glass is intentionally cooled at a slow, controlled rate to minimize or eliminate residual surface, edge compression, and center tension. During this process, called annealing, inclusions can undergo a phase transformation (α to β) and become stable without causing breakage.

When the glass is reheated during heat strengthening or full tempering, any existing NiS stones will shrink to their smaller, high-temperature stable α form. The slower cooling cycle used to make heat-strengthened glass allows the stones to complete this phase transformation. The author’s firm is unaware of a single confirmed case of spontaneous breakage of heat-strengthened glass due to NiS stone inclusions.

In contrast, the rapid cooling cycle used to produce fully tempered glass stops the phase transformation, thereby trapping the stones before they complete their volume growth. This can become problematic later when a glass is in-service and its temperature exposure restarts the phase transformation, triggering the volume growth of NiS stones and re-instigating conditions leading to breakage. Due to potential phenomenon, the author has a long-standing preference for the specification and use of heat-strengthened glass, except where tempered glass is mandated for safety or by code.