by Robert M. Chamra, EIT, and Kyle R. Gagnon

Masonry veneer is a common cladding type due to its aesthetics and perceived durability. However, the design documents provided to contractors frequently lack the necessary building code and industry standard requirements for constructing anchored masonry veneer, jeopardizing the long-term performance.

In particular, corrugated sheet-metal anchors—commonly referred to as ‘brick ties’—are routinely installed improperly due to the gap between project specifications and building code requirements. Supplementary specifications for brick ties are necessary to provide a code-compliant and durable masonry veneer.

The code and industry standard

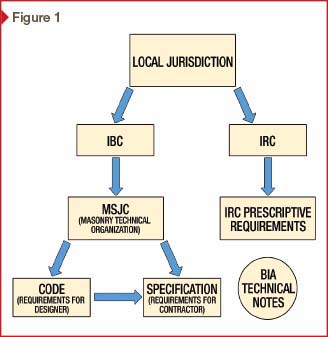

The design and construction of masonry veneer is governed by the codes adopted by each jurisdiction. Throughout most of the United States, the International Building Code (IBC) is commonly adopted with no amendments pertaining to the construction of masonry veneer. For anchored veneer requirements, it references sections of the Building Code Requirements for Masonry Structures (MSJC Code) developed by the Masonry Standards Joint Committee (MSJC). This committee comprises members of The Masonry Society (TMS), American Concrete Institute (ACI), and American Society of Civil Engineers (ASCE); therefore, the MSJC Code is also referred to as TMS 402, ACI 530, or ASCE 5 within the building code and contract documents.

Figure 1 outlines the flow of building code requirements for masonry veneer. For this article, it is assumed the masonry veneer will be constructed per IBC to facilitate discussion of the MSJC Code requirements.

The MSJC Code provides the minimum requirements for masonry structures and veneer to be used by the designer. The 2012 and 2015 IBC make direct reference to Sections 6.1 and 6.2 of the 2011 MSJC Code for anchored masonry veneer requirements. The 2013 MSJC Code is available, re-organized from the 2011 edition. The Section 6.1 and 6.2 requirements in the 2011 MSJC Code remain unchanged, but are now located in Sections 12.1 and 12.2 of the 2013 MSJC Code.

There are two design methods in the 2011 MSJC Code for anchored veneer: a prescriptive approach per Sections 6.1 and 6.2 (more commonly used in practice), and an alternative design using engineering mechanics to distribute loads from veneer to the backing and to limit out-of-plane deflection of the veneer. The prescriptive requirements specify the acceptable types of anchors for different types of construction, the anchor requirements, and installation requirements to obtain the intended performance. While this article focuses on the prescriptive approach, high-seismic or high-wind regions may be excluded from using this method and will need to provide an alternative design as discussed in the MSJC Code.

Specifications for Masonry Structures (MSJC Specification), a companion document to the MSJC Code, is commonly cited in contract documents as the minimum construction requirements for masonry, including anchored masonry veneers. (It is also referred to as TMS 602, ACI 530.1, or ASCE 6 in building codes and contract documents.) The preface to the MSJC Specification mentions:

the contractor should not be required through contract documents to comply with the [MSJC] Code or to assume responsibility regarding design requirements.

Without supplementary specifications from the designer, contractors are only responsible for the content in the MSJC Specification. While Sections 6.1 and 6.2 of the MSJC Code encompass 10 pages, the Specifications are expressed in only half a page. By only referencing the MSJC Specification, the designer would be failing to incorporate a majority of the building code requirements for anchored masonry veneer construction. It is therefore imperative for designers to specify the additional MSJC Code requirements which are not expressed in the MSJC Specification, to provide code-compliant and durable masonry veneer construction.

In addition to the building codes, the Brick Industry Association (BIA) has created several technical notes serving as industry standards for masonry construction. BIA Technical Notes 28, Brick Veneer/Wood Stud Walls, and 44B, Wall Ties for Brick Masonry, refer to IBC in outlining the requirements for anchored masonry veneer with additional discussion. While BIA Technical Notes are not intended to be referenced in contract documents, they are useful references for specifiers and contractors alike to understand the building code requirements of masonry veneer construction.

MSJC Code requirements included in the MSJC Specification

The MSJC Code and MSJC Specification overlap on four requirements for corrugated brick ties.

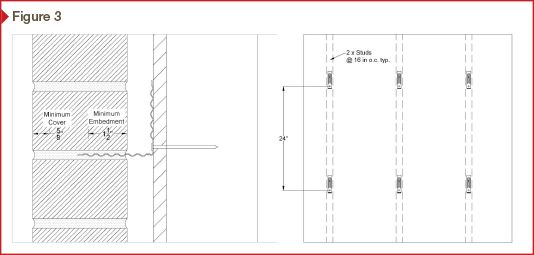

- Brick ties must be embedded 38 mm (11⁄2 in.) into mortar joints. The minimum embedment allows the brick tie to have enough mortar to resist imposed lateral loads.

- Each brick tie needs 16 mm (5⁄8 in.) of mortar cover, the mortar between the exterior of the veneer and the end of the horizontal leg of the tie. The minimum mortar cover provides corrosion protection for the end of the brick tie. Figure 2 illustrates a brick tie that did not meet minimum cover on a recent project; additional similarly installed brick ties were later found to be severely corroded.

- The maximum wall area is 0.25 m2 (2.67 sf) per tie, with maximum spacing limits of 813 mm (32 in.) horizontally and 635 mm (25 in.) vertically. This requirement will provide sufficient quantity and distribution of brick ties within the masonry veneer to resist the imposed lateral loads.

- The final requirement states ties should be spaced within 305 mm (12 in.) of openings greater than 406 mm (16 in.) at a spacing of no greater than 0.9 m (3 ft) on center (o.c.).

Figure 3 illustrates the brick tie requirements expressed in both the MSJC Code and MSJC Specification.

MSJC Code requirements that are not included in the MSJC Specification

While these requirements are important to the construction of masonry veneer, there are several others that form the basis of the prescriptive approach for designing brick ties that are not communicated in the MSJC Specification. If not constructed with those additional MSJC Code requirements, the quantity and distribution of brick ties may not be conservative enough, and result in premature failure of the masonry veneer. It is the responsibility of the designer to provide all the MSJC Code requirements necessary to construct the intended design.

Backing

One of the common errors in masonry veneer construction occurs when an incorrect tie is selected for the type of backing used. In the MSJC Code, corrugated sheet metal anchors are only allowed to be used with a wood-frame backing. Therefore, brick ties are not permitted to be attached to steel stud framing, concrete, or concrete masonry unit (CMU) backup walls.

While studies have shown corrugated brick ties do not perform well in high seismic or high wind areas, they have continued to perform well in typical wood-frame construction. (See Norbert Krogstad’s article, “Proper Use of Anchors,” from the December 2010 issue of Masonry Construction.) The designer must specify brick ties are only to be used with a wood-frame backing and provide alternative masonry anchors for other backing types.