Bridging the gap: Specifications for durable masonry veneer anchors

by Katie Daniel | January 8, 2016 2:40 pm

[1]

[1]by Robert M. Chamra, EIT, and Kyle R. Gagnon

Masonry veneer is a common cladding type due to its aesthetics and perceived durability. However, the design documents provided to contractors frequently lack the necessary building code and industry standard requirements for constructing anchored masonry veneer, jeopardizing the long-term performance.

In particular, corrugated sheet-metal anchors—commonly referred to as ‘brick ties’—are routinely installed improperly due to the gap between project specifications and building code requirements. Supplementary specifications for brick ties are necessary to provide a code-compliant and durable masonry veneer.

The code and industry standard

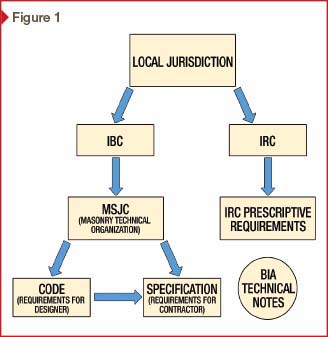

The design and construction of masonry veneer is governed by the codes adopted by each jurisdiction. Throughout most of the United States, the International Building Code (IBC) is commonly adopted with no amendments pertaining to the construction of masonry veneer. For anchored veneer requirements, it references sections of the Building Code Requirements for Masonry Structures (MSJC Code) developed by the Masonry Standards Joint Committee (MSJC). This committee comprises members of The Masonry Society (TMS), American Concrete Institute (ACI), and American Society of Civil Engineers (ASCE); therefore, the MSJC Code is also referred to as TMS 402, ACI 530, or ASCE 5 within the building code and contract documents.

Figure 1 outlines the flow of building code requirements for masonry veneer. For this article, it is assumed the masonry veneer will be constructed per IBC to facilitate discussion of the MSJC Code requirements.

The MSJC Code provides the minimum requirements for masonry structures and veneer to be used by the designer. The 2012 and 2015 IBC make direct reference to Sections 6.1 and 6.2 of the 2011 MSJC Code for anchored masonry veneer requirements. The 2013 MSJC Code is available, re-organized from the 2011 edition. The Section 6.1 and 6.2 requirements in the 2011 MSJC Code remain unchanged, but are now located in Sections 12.1 and 12.2 of the 2013 MSJC Code.

There are two design methods in the 2011 MSJC Code for anchored veneer: a prescriptive approach per Sections 6.1 and 6.2 (more commonly used in practice), and an alternative design using engineering mechanics to distribute loads from veneer to the backing and to limit out-of-plane deflection of the veneer. The prescriptive requirements specify the acceptable types of anchors for different types of construction, the anchor requirements, and installation requirements to obtain the intended performance. While this article focuses on the prescriptive approach, high-seismic or high-wind regions may be excluded from using this method and will need to provide an alternative design as discussed in the MSJC Code.

Specifications for Masonry Structures (MSJC Specification), a companion document to the MSJC Code, is commonly cited in contract documents as the minimum construction requirements for masonry, including anchored masonry veneers. (It is also referred to as TMS 602, ACI 530.1, or ASCE 6 in building codes and contract documents.) The preface to the MSJC Specification mentions:

the contractor should not be required through contract documents to comply with the [MSJC] Code or to assume responsibility regarding design requirements.

Without supplementary specifications from the designer, contractors are only responsible for the content in the MSJC Specification. While Sections 6.1 and 6.2 of the MSJC Code encompass 10 pages, the Specifications are expressed in only half a page. By only referencing the MSJC Specification, the designer would be failing to incorporate a majority of the building code requirements for anchored masonry veneer construction. It is therefore imperative for designers to specify the additional MSJC Code requirements which are not expressed in the MSJC Specification, to provide code-compliant and durable masonry veneer construction.

In addition to the building codes, the Brick Industry Association (BIA) has created several technical notes serving as industry standards for masonry construction. BIA Technical Notes 28, Brick Veneer/Wood Stud Walls, and 44B, Wall Ties for Brick Masonry, refer to IBC in outlining the requirements for anchored masonry veneer with additional discussion. While BIA Technical Notes are not intended to be referenced in contract documents, they are useful references for specifiers and contractors alike to understand the building code requirements of masonry veneer construction.

MSJC Code requirements included in the MSJC Specification

The MSJC Code and MSJC Specification overlap on four requirements for corrugated brick ties.

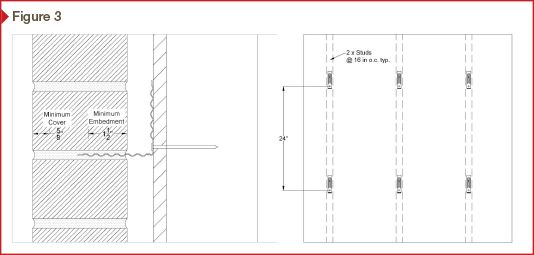

- Brick ties must be embedded 38 mm (11⁄2 in.) into mortar joints. The minimum embedment allows the brick tie to have enough mortar to resist imposed lateral loads.

- Each brick tie needs 16 mm (5⁄8 in.) of mortar cover, the mortar between the exterior of the veneer and the end of the horizontal leg of the tie. The minimum mortar cover provides corrosion protection for the end of the brick tie. Figure 2 illustrates a brick tie that did not meet minimum cover on a recent project; additional similarly installed brick ties were later found to be severely corroded.

- The maximum wall area is 0.25 m2 (2.67 sf) per tie, with maximum spacing limits of 813 mm (32 in.) horizontally and 635 mm (25 in.) vertically. This requirement will provide sufficient quantity and distribution of brick ties within the masonry veneer to resist the imposed lateral loads.

- The final requirement states ties should be spaced within 305 mm (12 in.) of openings greater than 406 mm (16 in.) at a spacing of no greater than 0.9 m (3 ft) on center (o.c.).

Figure 3 illustrates the brick tie requirements[2] expressed in both the MSJC Code and MSJC Specification.

MSJC Code requirements that are not included in the MSJC Specification

While these requirements are important to the construction of masonry veneer, there are several others that form the basis of the prescriptive approach for designing brick ties that are not communicated in the MSJC Specification. If not constructed with those additional MSJC Code requirements, the quantity and distribution of brick ties may not be conservative enough, and result in premature failure of the masonry veneer. It is the responsibility of the designer to provide all the MSJC Code requirements necessary to construct the intended design.

Backing

One of the common errors in masonry veneer construction occurs when an incorrect tie is selected for the type of backing used. In the MSJC Code, corrugated sheet metal anchors are only allowed to be used with a wood-frame backing. Therefore, brick ties are not permitted to be attached to steel stud framing, concrete, or concrete masonry unit (CMU) backup walls.

While studies have shown corrugated brick ties do not perform well in high seismic or high wind areas, they have continued to perform well in typical wood-frame construction. (See Norbert Krogstad’s article, “Proper Use of Anchors,” from the December 2010 issue of Masonry Construction.) The designer must specify brick ties are only to be used with a wood-frame backing and provide alternative masonry anchors for other backing types.

Tie properties

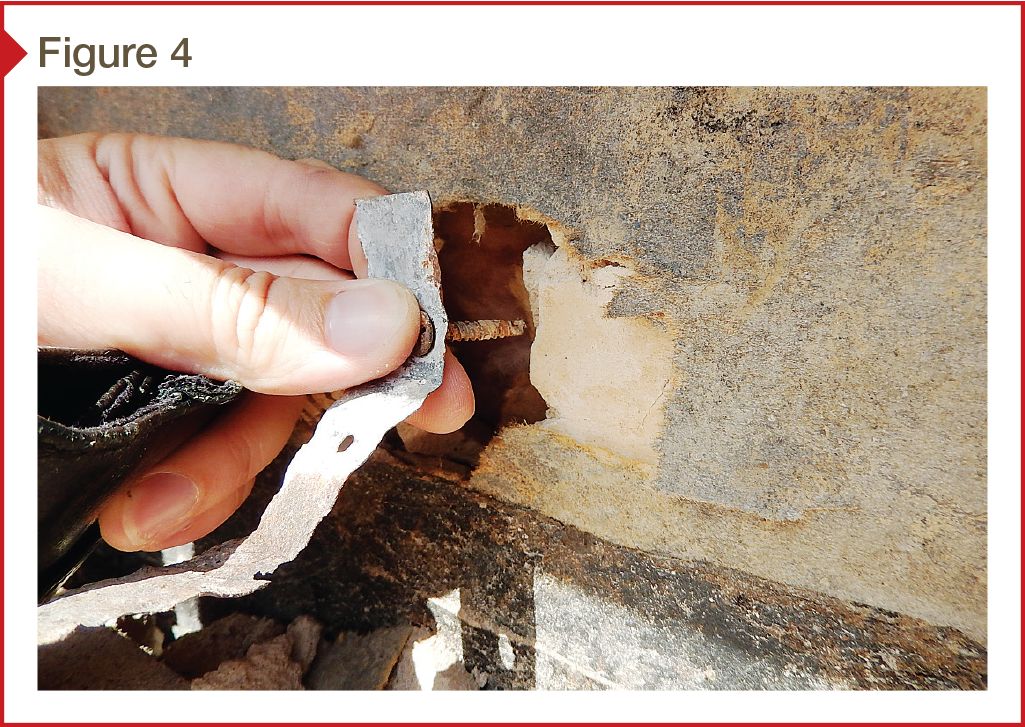

The MSJC Specification says nothing regarding the type and properties of a brick tie. However, the MSJC Code requires the tie to be a minimum 22 gage or 0.8 mm (0.03 in.) in thickness and 22.2 mm (7⁄8 in.) in width. It also requires a corrugation wavelength and amplitude range of 7.6 to 12.7 mm (0.3 to 0.5 in.) and 1.5 to 2.5 mm (0.06 to 0.1 in.), respectively.

Studies have shown insufficient width, wavelength, and amplitude can contribute to decreased mortar pullout strength in tension. (See the article by James M. LaFave and Dziugas Reneckis, “Structural Behavior of Tie Connections for Residential Brick Veneer Construction,” published in The Masonry Society Journal in December 2005). Insufficient gage thickness can lead to the fastener punching through the tie in tension, as shown in Figure 4, as well as decreased compressive resistance due to buckling of the tie. It is the responsibility of the designer to specify a code-compliant brick tie as further discussed in Part 3 of the “Mandatory Requirements Checklist” within the MSJC Code.

Corrosion protection of corrugated brick ties is commonly provided by hot-dip galvanizing. While galvanizing is discussed and acceptable in both the MSJC Code and MSJC Specification, stainless steel brick ties are available; the marginal additional cost can extend the life of masonry veneer by decades. The additional cost of using stainless steel masonry anchors pales in comparison to the cost of replacing masonry veneer within the life of a building. The designer should specify stainless steel masonry anchors to increase the durability of masonry veneer construction. (See Clayford T. Grimm’s article, “Corrosion Protection of Metal Connectors in Masonry,” published in the December 2002 TMS Journal.)

Fastener properties

Similar to tie properties, the MSJC Specification does not discuss the fastener type to be used to secure the brick ties to the backing. The MSJC Code requires an 8d common nail or better as the minimum fastener requirement for brick ties. If all other variables are code-compliant, fastener pullout strength controls the tensile capacity of the brick tie connection.

A common error is to use roofing nails or a smaller 6d common nail. These nails have a smaller shank diameter and shorter length, which can significantly decrease the overall pullout strength of the fastener. Using a non-code compliant fastener can decrease the tie capacity up to 50 percent. (See the article by James M. LaFave and Dziugas Reneckis, “Structural Behavior of Tie Connections for Residential Brick Veneer Construction,” published in The Masonry Society Journal in December 2005). Figure 5 shows the size of code-compliant fasteners next to those erroneously used in practice.

Fastener-pullout capacity in wood depends on its moisture content, especially when smooth shank common nails are used. If the fasteners are installed to a wood backing that has a higher moisture content than it will have in service (e.g. rainy or wet conditions), studies recommend using ring-shank nails or screws. To ensure durable masonry veneer, the designer should specify a code-compliant fastener and consider the environmental conditions of the installation.

Bending the tie

Equally critical to the tie and fastener properties is the fastener’s location with respect to the tie. The MSJC Code requires the fastener be located within 12.7 mm (1⁄2 in.) of the 90-degree bend when using the prescriptive approach. Two errors can occur when this requirement is omitted. The first is the tie must be bent at 90 degrees to be MSJC Code-compliant. This becomes an issue when the location of the brick tie does not match up vertically with the location of the mortar joint; at that point, masons tend to adjust brick ties by bending them into a number of different non-code compliant configurations, as shown in Figure 6.

These profiles of tie installation decrease the stiffness of the connection significantly as the excess length of tie within the air space straightens out, resulting in significant out-of-plane deflections to the entire veneer before engaging the brick tie. In conjunction with the 90 degree bend requirement, the mason’s workmanship is essential to ensure the brick tie locations and bed joints line up to avoid inappropriate bending of the brick ties.

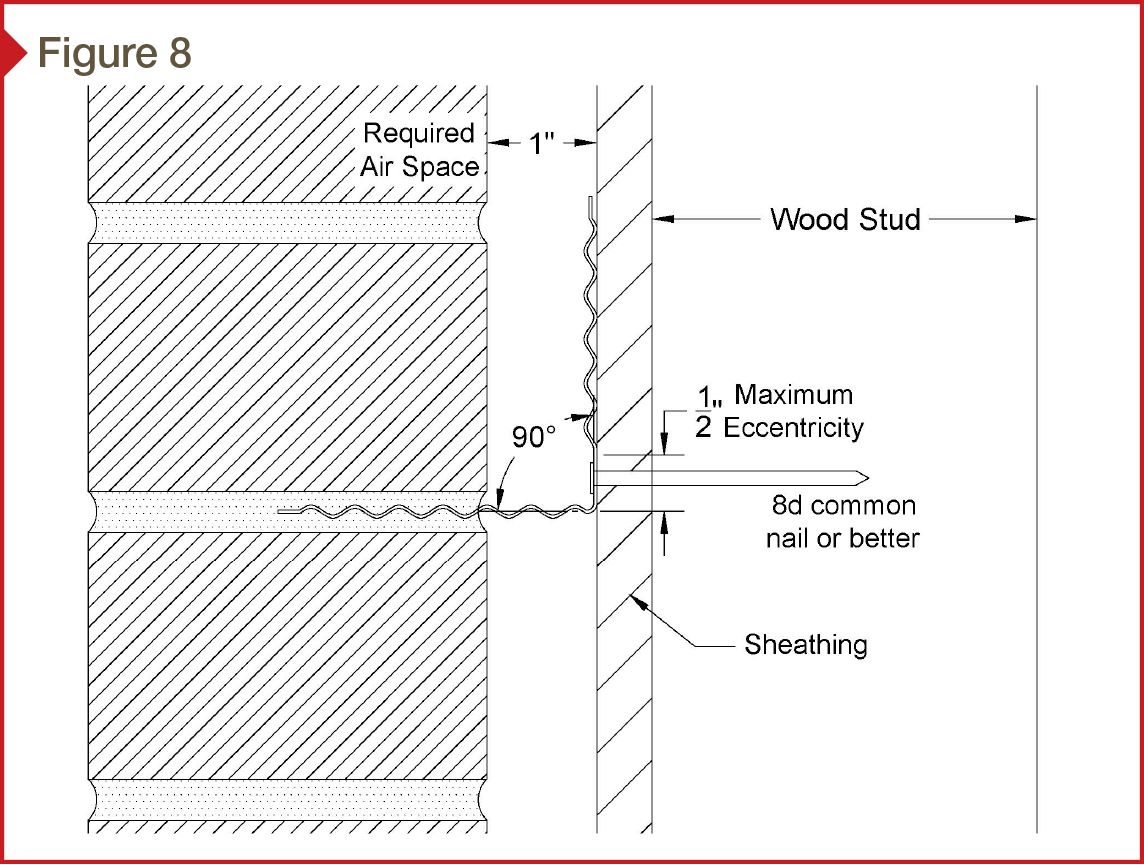

Fastener-to-bend location

The second requirement for placement of the fastener within 12.7 mm (1⁄2 in.) of the 90-degree bend is meant to decrease the eccentricity of the connection, which is the offset distance between the horizontal leg of the tie and the fastener above it. Fasteners with significant eccentricity allow for more displacement of the tie as it bends prior to engaging the fastener. The consequences for this mistake are similar to failing to provide a 90-degree bend in the tie: significant deflections at less than design loads, which can result in premature failure of the veneer.

Several studies have concluded the MSJC Code maximum of 12.7 mm (1⁄2 in.) of eccentricity may even be too big. (See the article by James M. LaFave and Dziugas Reneckis, “Structural Behavior of Tie Connections for Residential Brick Veneer Construction,” published in The Masonry Society Journal in December 2005). Figure 7 illustrates varying fastener-to-bend locations, with the middle and right configurations being ranges of code compliance, and the left being non-compliant (See H. Okail et al’s article, “Seismic Performance of Clay Masonry Veneer,” from the 14th World Conference on Earthquake Engineering, published in October 2008. Also, refer to the advisory provided by the Federal Emergency Management Agency (FEMA) in 2005 entitled, “Attachment of Brick Veneer in High-wind Regions”).

Air space

All masonry veneer anchors require a minimum air space (cavity width) and a maximum distance between the backing and the veneer. For corrugated brick ties, both the code minimum and maximum nominal values are the same: 25 mm (1 in.). The minimum air space allows enough space for moisture to drain down the weather resistive barrier. If the wall cavity is larger than 25 mm (1 in.), the capacity of the brick ties decreases. For wall sections necessitating a larger cavity width, such as those with continuous insulation, an alternative masonry anchor will be necessary. The designer must specify a 25-mm (1-in.) cavity width with brick ties to provide a functional drainage plane while maintaining the full capacity of the brick ties.

Recommendations

When specifying corrugated sheet metal anchors for masonry veneer, it is important for designers to convey all the code requirements to the contractor. In addition to referencing the MSJC Specification, designers must also include the following brick tie requirements in the contract documents if utilizing the prescriptive approach, as summarized in Figure 8:

- Use with wood-frame backing only.

- Use a code-compliant tie with sufficient gage thickness, width, corrugation wavelengths, and corrugation amplitude.

- Fasten with an 8d common nail or better.

- Provide a 90-degree bend in the brick tie.

- Place the fastener within 12.7 mm (1⁄2 in.) of the 90-degree bend in the brick tie.

- Provide a 25-mm (1-in.) cavity width.

Additionally, designers can extend the service life of masonry veneers by specifying stainless steel brick ties instead of the commonly used galvanized ones. By supplementing the MSJC Specification with these design-related decisions, specifiers can provide contractors with all the information necessary to construct a code-compliant masonry veneer. For conditions that cannot meet these requirements, designers can specify other masonry anchor types. By understanding and specifying a code-compliant masonry veneer, designers can improve the durability of masonry veneer construction. (The authors gratefully acknowledge the continuing support and leadership of David W. Fowler, PhD, PE—the faculty advisor for the research being performed at The Durability Lab, a testing center at the University of Texas at Austin).

Robert M. Chamra, EIT, is a project engineer with Building Diagnostics Inc., specializing in the investigation of problems with existing buildings, designing remedies for those problems, and monitoring the construction of the remedies. He participates in the research being performed at The Durability Lab—a testing center established by Building Diagnostics at the University of Texas at Austin. He can be reached by e-mail at rchamra@buildingdx.com[3].

Kyle R. Gagnon is a graduate student studying architectural engineering at the University of Texas at Austin. He serves as the graduate research assistant for The Durability Lab, which researches and tests the durability of building components, identifying factors causing premature failure. He can be contacted at kgagnon@buildingdx.com[4].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2016/01/anchors_Cover.jpg

- brick tie requirements: http://www.constructionspecifier.com/durability-of-brick-veneer-a-deeper-look-at-masonry-anchors

- rchamra@buildingdx.com: mailto:rchamra@buildingdx.com

- kgagnon@buildingdx.com: mailto:kgagnon@buildingdx.com

Source URL: https://www.constructionspecifier.com/bridging-the-gap-specifications-for-durable-masonry-veneer-anchors/