Building for better fire resilience in WUI zones

Canada’s National Research Council (NRC) published a new WUI guide, National Guide for Wildland-Urban Interface Fires, in July 2021, which provides detailed insight about WUI fire characteristics and associated hazards. For example, “the descent and landing of burning embers downwind, ahead of a burning fire, is referred to as spotting or, in the case of the WUI, ember rain.”2 Since embers from wildfires fall, start by looking at the roof assembly, then walls, any exterior structures, and then to the outside landscaping around the home.

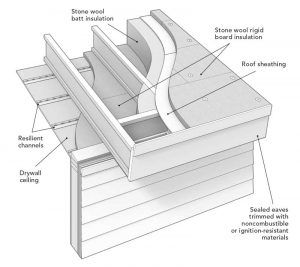

Roofs

A fire-resistant roof assembly includes not just the surface product, but also the underlayment, sheathing, insulation, joists, and other components that comprise a roof assembly. ASTM E108, Standard Test Methods for Fire Tests of Roof Coverings, Class A-rated surfaces such as clay, concrete, slate, and many types of asphalt or metal are good surface selections, but builders also need to consider components beneath the surface material. For example, noncombustible roof boards can improve the roof assembly’s fire resilience. There are noncombustible options, including several stone wool products. Builders should look for products with a flame-spread index of zero and a smoke-developed index of zero, which can improve a roof assembly’s ability to withstand conditions during a wildfire.

Other measures for creating a fire-resistant roof assembly include:

- Sealing eaves and covering valleys with an ASTM E108 Class A material to prevent embers from igniting the roof.

- When gaps exist within a roof system, filling the space at the eave ends to prevent ember and flame entry.

- Covering vents with 3.175-mm (0.125-in.) mesh to prevent embers from getting into the house.

- Using ignition-resistant or noncombustible materials, such as metal and fiber cement, for the soffit and fascia to further protect the eaves.

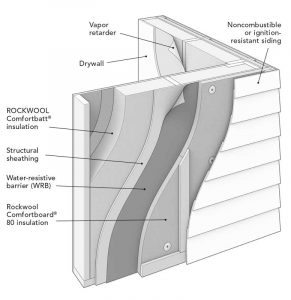

Walls

Similarly for wall design, fire-resistant cladding is not a complete solution. One must consider all components of the wall assembly as its strength is a function of the combination of materials that make it up. Vinyl siding does not provide a lot of protection, nor is it the problem when it comes to fire-prone assemblies. Vinyl typically does not burn. It tends to melt and fall away from the structure. It is the materials behind the vinyl siding that can either make or break the system.

While noncombustible or ignition-resistant materials such as fiber cement, stucco, plaster, brick, and stone are preferred siding, it is possible to comply with state codes such as the California Building Code’s Chapter 7A—which stipulates materials and construction methods for wildfire exposure—even when using another product (e.g. vinyl siding). This means complying with the State Fire Marshal Standard SFM 12-7A-1, now adopted into ASTM as E2707, Standard Test Method for Determining Fire Penetration of Exterior Wall Assemblies Using a Direct Flame Impingement Exposure, which tests the ability of the wall assembly to resist the penetration of flames into the stud cavity.