The panels are designed to resist dead loads, live loads, and wind loads. Their structural characteristics allow them to meet and even exceed the most stringent building code requirements. In addition to exterior envelopes, IMPs can be used for interior walls and ceilings, as they are able to support human weight, allowing access for maintenance purpose. Note, although reinforcement is not necessary, by its sandwich composition, the metal faces adhered to the insulation core create a strong and rigid element that can be used as a ceiling panel that could allow for maintenance activities on the ceiling.

Hassle-free installation

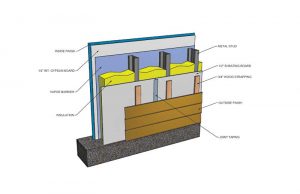

One of the most attractive advantages of using IMPs as building envelopes is their quick and cost-effective installation. Pre-assembled IMPs are installed in a single step once they arrive at the construction site, reducing installation times by about 50 percent, significantly lowering labor costs and guaranteeing consistency compared to multi-material systems, which require up to 11 steps to install (Figure 1), multiplying the risk of mistakes and failure of the components in the building envelope. The lightweight panels also require fewer parts to complete installation, which simplifies sequencing and permits the building envelope to be enclosed faster, allowing interior work to begin sooner and, therefore, decreasing overall construction time and costs.

IMPs not only reduce the number of hours, workforce, and temporary equipment (e.g. trailers, toilets, etc.) required on-site, but also help to maintain a predictable construction schedule and budget, even in adverse weather conditions. Optimized operations on-site will help free up valuable resources for other projects.

Cost-effective long-term solution

A simpler installation process is not the only reason driving the rising trend of using IMPs as a building envelope solution. IMPs are currently one of the most cost-effective cladding solutions on the market as it lowers energy costs (heating and cooling due to high thermal performance). Their long-term durability lowers buildings’ maintenance costs compared to conventional envelope systems due to available 20-year finish warranties. Fewer joints in the building envelope require less maintenance over time. In addition to their strength and insulating properties, continuous panels are highly weather- and corrosion-resistant, which makes them appealing for cold climate and coastal regions. The steel is pre-painted with a variety of colors and paint systems, from siliconized modified polyester (SMP) to polyvinylidene fluoride (PVDF), using the latest color technologies. This improves color retention and limits fading due to prolonged ultraviolet (UV) exposure, so the building can maintain its aesthetic appeal over time.

The next generation of green architecture

IMPs are not only recognized for their longevity and cost-efficiency, but also for their environmental sustainability. They are a smart choice for green construction projects, as well as those requiring lower emissions. The quality of the materials used, their eco-responsible manufacturing process, and the panels’ superior insulating properties make them a greener solution that considerably reduces environmental impact compared to conventional building enclosure solutions.