Sustainable design

The most important contributions of luminous ceilings to the cause of green building are reducing energy consumption and improving occupant wellbeing and productivity due to improved lighting quality.

Vinyl is ‘red-listed’ by some organizations that are promoting building sustainability, primarily due to concerns about the chemicals used to manufacture the material and the toxicity of fumes produced during combustion. The authors suggest there are no intrinsically green building products, only intelligently used products. With that in mind, it is important to examine the case for and against vinyl.

Some vinyl materials contain phthalates, heavy metals, plasticizers, and chemicals of concern. However, some ceiling manufacturers use rigid vinyl, also known as unplasticized polyvinyl chloride (uPVC), that does not contain these precursor materials and is produced by companies with more stringent environmental controls. Their panels, moreover, are available with the GreenGuard Gold certification of being low in volatile organic compound (VOC) emissions.

With regard to combustion, PVC compounds, in general, are “among the more fire-resistant common organic polymers, natural or synthetic.”9 Toxicity of the products of combustion should be considered in the context of the minimal mass of the material. Further, suspended panels fall to the relatively cooler floor of a burning building, where they are less likely to contribute fuel during the critical early stages of a fire.

Panels are typically about 0.33 mm (0.013 in.) thick, and weigh about 0.5 kg/m2 (0.1 psf)—approximately one-fifth the mass of material used to make mineral fiber ceiling panels. Panels also nest compactly. These properties reduce the environmental burden of manufacturing, shipping, and handling thermoformed panels.

Beyond the environmental impact of making a product, it is important to consider the material’s life cycle performance. Vinyl does not easily decompose—this is a negative quality in a landfill or ocean, but a desirable one in a building. Thermoformed ceiling panels are not affected by water, will not support mold or fungi, and can be washed clean of most stains. The panels are robust and unlikely to be damaged during handling or maintenance. They contain an ultraviolet (UV) inhibitor and are very resistant to discoloration. If removed for redecorating or at the end of a building’s life cycle, panels can often be salvaged and reused; if not, they can be recycled and formed into new panels.

The resin identification code for vinyl is ‘3,’ with many communities accepting scrap from installation of luminous ceiling panels in their curbside recycling programs. One thermoformed ceiling tile manufacturer will take back scrap from customers, combine it with in-house scrap, and produce new panels with more than 98 percent recycled material content. The high-quality polymers can be reused repeatedly without downcycling performance.

Transluminous ceilings

Richard Kelly, the pioneering architectural lighting designer, categorized the “three elements in the perceptions of

visual design:”

- focal glow or highlight;

- ambient luminescence or graded washes; and

- play of brilliants or sharp detail. (See Huggett and Levin’s “Toxicity of the Pyrolysis and Combustion Products of Poly [Vinyl Chloride]: A Literature Assessment,” published in vol. 11 [1987] of Fire and Materials. )

The strength of luminous ceiling schemes inherited from the 20th century is their ambient luminescence. Kelly says it is:

the uninterrupted light of a snowy morning in the open country. It is foglight at sea in a small boat, it is twilight haze on a wide river where shore and water and sky are indistinguishable… Ambient luminescence produces shadowless illumination. It minimizes form and bulk. It minimizes the importance of all things and people. It suggests the freedom of space and can suggest infinity. It is usually reassuring. It quiets the nerves and is restful… It is any art gallery with strip-lighted walls, translucent ceiling, and white floor.

Luminous ceilings have evolved to now provide the other two elements of lighting, described by Kelly as:

Focal glow is the campfire of all time… It is the pool of light at your favorite reading chair. It is the shaft of sunshine that warms the end of the valley… Focal glow draws attention, pulls together diverse parts, sells merchandise, separates the important from the unimportant, helps people see …

Play of brilliants is Times Square at night. It is the 18th-century ballroom of crystal chandeliers and many candle flames… Play of brilliants excites the optic nerves, and in turn stimulates the body and spirit, quickens the appetite, awakens curiosity, sharpens the wit. It is distracting or entertaining.

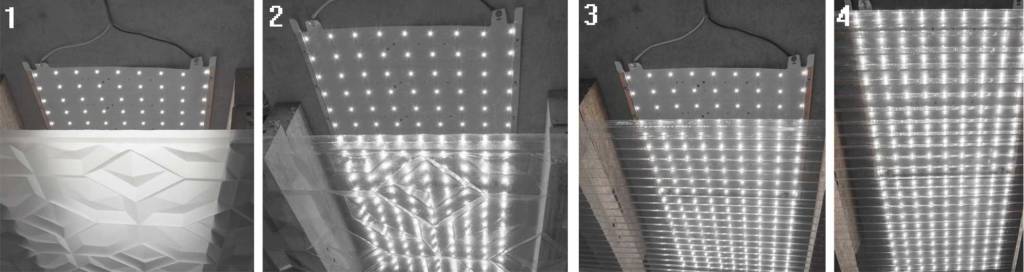

‘Focal glow’ can be achieved by variations in the intensity of light color from the transluminous ceiling. ‘Play of brilliants’ is the sparkle created when light shines through panel perforations or the facets of a clear panel.