Ceilings become transluminous

by Katie Daniel | August 1, 2017 10:06 am

[1]

[1]by Ed Davis, David Condello, and Michael Chusid, RA, FCSI, CCS

Human sight evolved to optimize vision under diffuse sky radiation, and this remains the best illumination conditions for most of our activities. Luminous ceilings are an attempt

to reproduce the qualities of such overhead lighting in an indoor environment.

A luminous ceiling system is designed to provide a substantially uniform level of illuminance throughout the room below. The entire ceiling is, in effect, one large luminaire consisting of a continuous surface of light-transmitting material of a diffusing or light-controlling character, with light sources mounted above it. (This definition is based on American National Standards Institute/Illuminating Engineering Society of North America [ANSI/IES] RP-16-10, Nomenclature and Definitions for Illuminating Engineering. Opaque ceilings with indirect lighting can also provide uniform illuminance, but do not meet the IES definition requiring transilluminated surfaces. Open-cell ceilings are similar to luminous ceilings in that light sources are located above ceilings, but the light sources remain visible when the ceiling is viewed at a high angle, the visual effect of an illuminated surface is lost, and the ceiling does not create the psychological impact of a physical boundary to the room.) A complementary definition recognizes a luminous ceiling is also an interior finish system with a light-emitting surface. As such, the ceiling has to meet architectural and interior design criteria including fire safety, acoustic, and other specification considerations.

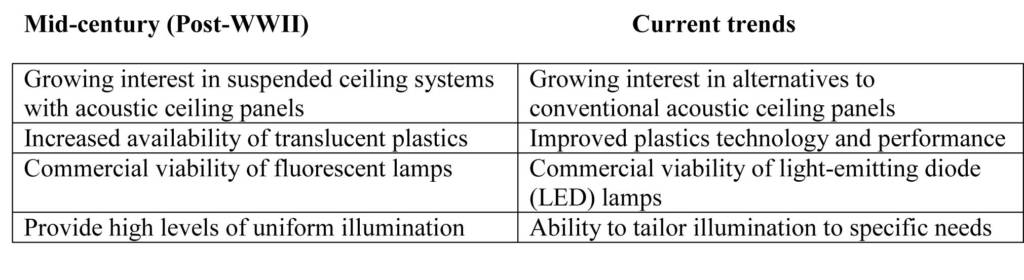

While there are 19th-century antecedents, luminous ceilings are an innovation of the Mid-Century Modern era, and were spawned by postwar availability of plastic and fluorescent light, as well as the growing popularity of noise-reducing ceiling panels and suspended ceiling grids. (See, for example, US Patent 2710335−Light Diffusing and Sound Absorbing Unit; H.K. Wong, Inventor; published June 7, 1955 at www.google.com/patents/US2710335[2].) They were perfectly suited for the clean lines, uncluttered surfaces, and minimalist volumes of Modern architecture. Figure 1 compares conditions in that period to current trends, offering insight into why the luminous ceiling concept is currently enjoying both a renaissance and a reinterpretation.

[3]

[3]From the outset, thin sheets of thermoformed rigid vinyl have been the most widely used material for luminous ceilings. For example, a paper presented at a 1955 conference sponsored by the National Academy of Sciences says, “With the luminous ceiling[4], we have a new form of lighting providing a major environmental influence upon the building inhabitant.”

Regarding vinyl, the presenter states:

The tests showed that a rigid vinyl copolymer exhibits outstanding light stability and uniform diffused light transmission, as well as a high degree of dimensional stability, chemical resistance, and tensile and compressive strength. This rigid sheet is inherently tough, possesses excellent aging properties, and offers an ease of fabrication and handling suitable for luminous ceilings.

The paper also points out the material meets fire safety requirements and controls glare before concluding, “the appearance of the luminous ceiling is outstanding. It provides a light and airy interior which seems very attractive. All in all, the luminous ceiling has created a pleasing and practical office environment.” (Other materials that can be used for luminous ceilings include various thermoplastic and thermoset plastic sheets, tensioned fabric and vinyl systems, metal panels with large percentages of perforated open area, extruded multi-cell plastic sheets, light-transmitting resin panels, glass, and even paper. While each material has unique characteristics and limitations, the plethora of options ensures there is a luminous ceiling system to satisfy almost every building’s design criteria.)

The attributes described in the 62-year-old paper have withstood the tests of time, and there have been many small, incremental improvements to thermoformed vinyl ceiling panels. (For more, see the September 2014 article[5] in The Construction Specifier by the authors.) However, the evolution of luminous ceilings has accelerated since the turn of the millennium in response to new light sources, ceiling panels with a range of light transmission levels, patterned or textured ceiling surfaces that alter the flow of light, and contemporary aesthetic sensibilities.

The term ‘transluminous’ is suggested to expand traditional concepts about luminous ceilings and embrace the full range of light-transmitting ceiling designs. While ‘luminous’ implies that light emits from, or is present on, a ceiling’s surface, the term ‘transluminous’ recognizes a wider range of architectural effects based on what is above, within, and beneath light-transmitting ceiling panels.

[6]

[6]Lighting quality

The decision to use luminous ceilings often begins as a strategy to improve lighting quality. Conventional lighting schemes—especially those using surface-mounted or recessed luminaires—result in ceilings having contrasting areas of brightness, ranging from intense direct light beneath fixtures to areas in shadow or only dimly illuminated by reflected or indirect light. Such variations in brightness create excessive luminous ratios that cause glare and detract from visual quality.

Glare decreases the comfort and efficiency of building occupants, especially if they are performing tasks that require visual acuity. This is made clear in the WELL Building Standard, a program advocating for the wellbeing of people that live and work within buildings. The standard repeatedly warns about detrimental impacts of glare, stating:

Non-diffuse, bright indoor lights create uneven levels of brightness in the visual field. The resulting glare… can cause visual discomfort (discomfort glare), fatigue, visual impairment and even injury (disability glare), and can be attributed to either direct or reflected glare. (This comes from the International WELL Building Institute’s WELL Building Standard, V1, Q2 2017 Version; Feature 55[7].)

The problem is exacerbated among individuals with poor eyesight—a special concern with an aging population. Consideration must also be given to individuals, including infants or the infirm who may be laying on their backs, looking directly into harsh glare. Light-emitting diodes (LEDs) can also often contribute to glare because they concentrate a strong light source into a smaller area than do incandescent and fluorescent lamps with equal luminous flux.

[8]

[8]Luminous ceilings, on the other hand, typically provide diffuse illumination. While they can be designed to any level of illumination desired, their light emits across a large surface of relatively low brightness to distribute substantially uniform light and reduce glare. For this reason, luminous ceilings are frequently used in museums, showrooms, and other spaces requiring glare-free illumination.

Lighting design

Designers have traditionally wanted luminous ceilings to provide shadow-free, uniformly bright ceilings. For the greatest lighting uniformity and efficiency, structural elements above the ceiling, and the bottom surfaces of above-ceiling ducts and equipment, should be painted to have high light-reflectance values (LRV). This helps distribute light within the above-ceiling cavity to improve its uniformity; directing luminaires upward also boosts distribution by reflecting light off the structure. Above-ceiling equipment and services should be located to avoid casting unwanted shadows onto ceiling panels.

An alternative design intent that is now emerging welcomes non-uniformly bright transluminous ceilings; it allows the locations of above-ceiling lamps, pipes, and equipment to be ascertained from below. This has been fostered by several trends, including:

- widespread use of exposed-structure ceilings has accustomed the public to seeing the overhead ‘guts’ of buildings;

- desire to reduce energy consumption in buildings has created interest in luminous ceiling panels with higher light-transmittance values, trading light diffusion for lighting efficiency; and

- a paradigm shift from saturating rooms with high lumen levels to creating a blend of ambient and task lighting.

The standard material used for luminous ceilings has been translucent white panels with relatively low light-transmission values (LTVs) yet excellent light diffusion. In response to the trends just cited, thermoformed ceiling panels are also now made from clear and frosted clear vinyl; these options have higher LTVs that result in better energy utilization yet less diffusion.

The aesthetic potential of clear ceiling panels is just starting to be explored. Clear panels challenge the viewer’s assumptions about ceilings—is it a surface or an idea? A boundary that contains the room or a separator between adjoined volumes? Is the ceiling that which sits in the bottom of a suspension system, the bottom of the roof or floor structure above, or the totality of everything overhead? Is the meaningful architecture the ceiling surface or the mechanical art usually hidden above?

While architectural philosophers and critics argue the meaning and merits, we have already seen examples of clear ceiling panels that sparkle as light catches their edges and molded surfaces. They can be interspersed among opaque and frosted panels to create variations in light transmission and appearance, or arrayed randomly or periodically to reveal larger-scale patterns.

For their functional benefits, clear panels are used in computer server farms, laboratories, and similar spaces to separate the air in an occupied space from an above-ceiling cavity with different temperature, ventilation, hygienic, or other requirements while allowing for visual connection and borrowed light. These assemblies are also specified as peek-a-boo panels beneath equipment that needs visual observation or beneath spotlights and flood lights to semi-conceal the fixtures while allowing use of lower-cost, non-appearance-grade models.

[9]

[9]It may be a stretch to describe variations in a luminous ceiling surface as a ‘biophilia’ strategy, but natural environments have non-uniform illumination—clouds constantly change the skyscape, and walking under a forest canopy animates light and shadow. Like the patterns in stone, wood, or a patinated metal, variation can make a surface more interesting. The eye easily adjusts to subtle variations in brightness.

Some luminous ceilings earn recognition as biophilic by offering graphic or simulated representations of the sky. Several companies, for example, offer light-transmitting photographic panels that are very realistic, especially when set in recessed frames enhancing an illusion of depth. The authors have experimented with artificial ‘leaves’ installed above luminous panels; the leaves sway gently in response to airflow and vibrations to cast moving shadows emulating a mottled arboreal canopy.

Another approach is to program red, green, and blue LED lamps to replicate circadian changes in the color of skylight and the movement of simulated clouds. (Red, green, and blue [RGB] are primary colors of light—they can be blended to create white and any color of illumination.) The same technique is used to change the scene and establish a mood according to the time of day. Restaurants, for example, can change the color for each of their dayparts—soft lighting for the breakfast trade, full-spectrum daylight to hurry crowds through the lunch rush, warmer hues to relax diners, and pulsing colors for nighttime revelers.

Alternatively, colored LEDs can be used as pixels to turn luminous ceiling panels into a dynamic canvas for entertainment or to communicate vital information. Visitors to a hospital, for example, can be given a transponder that communicates with the ceiling to create an overhead yellow brick road leading to their destinations. Emergency lighting can flash panels in sequence to direct occupants to exits.

Another option involves rear projection. In this strategy, translucent and frosted ceiling panels function as screens for video or still images projected from above. This can be used to create sky scenery, art installations, or entertainment displays. The option is also receiving interest from retailers and the hospitality industry for branding and promotional placements.

[10]

[10]Architectonic considerations

Various architectonic considerations are explored in the following paragraphs.

Fire safety

It is important to specify thermoformed panels with Class A surface burning characteristics and self-extinguishing plastic composition. Class A indicates

a 25 maximum flame spread and a 450 maximum smoke development when tested according to ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials. Self-extinguishing vinyl is V0-rated under Underwriters Laboratories (UL) 94, Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. It is critical to always comply with any requirements of the authorities having jurisdiction (AHJs).

Sprinklers

Hiding luminaires above panels helps create a clean, uncluttered ceiling—one of the principal reasons for using luminous assemblies. This can be enhanced by also placing fire sprinklers above ceiling panels that will drop out when exposed to heat, which is a characteristic available with some thermoformed vinyl ceiling products. The thermoplastic softens at approximately 57 C (135 F), before sagging and then falling to the relatively cooler floor without melting or burning. This allows heat to rise to the now-exposed fire sprinklers so they can activate at about 66 C (150 F) and do their duty.

Drop-out ceilings must comply with National Fire Protection Association (NFPA) 13, Standard for the Installation of Sprinkler Systems, and be listed or approved by building code evaluation services such as International Association of Plumbing and Mechanical Officials Uniform Evaluation Service (IAPMO UES), FM Global, and UL. As many local AHJs have limited experience with drop-out ceiling[11] systems, it can be useful discussing the topic with them while still preparing construction documents.

Sprinklers and related piping should be located where they will not cast unacceptable shadows on the luminous ceiling.

Acoustic

When acoustic vibrations (i.e. noise) impinge on the bottom of a lightweight suspended ceiling panel, the panel acts as a diaphragm and transfers mechanical energy into the above-ceiling cavity, where it is dampened by the viscous mass of air in cavity. Tests following ASTM C423, Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method, should use Type E mounting to hold specimens above the test chamber floor to simulate cavity depth.

While results vary depending on manufacturer, material thickness/formulation, and panel style, thermoformed ceiling panels have noise reduction coefficients (NRCs) of about 0.25 or 0.30 with a backer panel. Perforated panels can have an NRC of up to 0.40. These values make thermoformed panels suitable for a wide range of occupancies. Additional noise reduction can be obtained by installing acoustic insulation in the ceiling cavity.

[12]

[12]Sustainable design

The most important contributions of luminous ceilings to the cause of green building are reducing energy consumption and improving occupant wellbeing and productivity due to improved lighting quality.

Vinyl is ‘red-listed’ by some organizations that are promoting building sustainability, primarily due to concerns about the chemicals used to manufacture the material and the toxicity of fumes produced during combustion. The authors suggest there are no intrinsically green building products, only intelligently used products. With that in mind, it is important to examine the case for and against vinyl.

Some vinyl materials contain phthalates, heavy metals, plasticizers, and chemicals of concern. However, some ceiling manufacturers use rigid vinyl, also known as unplasticized polyvinyl chloride (uPVC), that does not contain these precursor materials and is produced by companies with more stringent environmental controls. Their panels, moreover, are available with the GreenGuard Gold certification of being low in volatile organic compound (VOC) emissions.

With regard to combustion, PVC compounds, in general, are “among the more fire-resistant common organic polymers, natural or synthetic.”9 Toxicity of the products of combustion should be considered in the context of the minimal mass of the material. Further, suspended panels fall to the relatively cooler floor of a burning building, where they are less likely to contribute fuel during the critical early stages of a fire.

Panels are typically about 0.33 mm (0.013 in.) thick, and weigh about 0.5 kg/m2 (0.1 psf)—approximately one-fifth the mass of material used to make mineral fiber ceiling panels. Panels also nest compactly. These properties reduce the environmental burden of manufacturing, shipping, and handling thermoformed panels.

Beyond the environmental impact of making a product, it is important to consider the material’s life cycle performance. Vinyl does not easily decompose—this is a negative quality in a landfill or ocean, but a desirable one in a building. Thermoformed ceiling panels are not affected by water, will not support mold or fungi, and can be washed clean of most stains. The panels are robust and unlikely to be damaged during handling or maintenance. They contain an ultraviolet (UV) inhibitor and are very resistant to discoloration. If removed for redecorating or at the end of a building’s life cycle, panels can often be salvaged and reused; if not, they can be recycled and formed into new panels.

The resin identification code for vinyl is ‘3,’ with many communities accepting scrap from installation of luminous ceiling panels in their curbside recycling programs. One thermoformed ceiling tile manufacturer will take back scrap from customers, combine it with in-house scrap, and produce new panels with more than 98 percent recycled material content. The high-quality polymers can be reused repeatedly without downcycling performance.

[13]

[13]Transluminous ceilings

Richard Kelly, the pioneering architectural lighting designer, categorized the “three elements in the perceptions of

visual design:”

- focal glow or highlight;

- ambient luminescence or graded washes; and

- play of brilliants or sharp detail. (See Huggett and Levin’s “Toxicity of the Pyrolysis and Combustion Products of Poly [Vinyl Chloride]: A Literature Assessment,” published in vol. 11 [1987] of Fire and Materials[14]. )

The strength of luminous ceiling schemes inherited from the 20th century is their ambient luminescence. Kelly says it is:

the uninterrupted light of a snowy morning in the open country. It is foglight at sea in a small boat, it is twilight haze on a wide river where shore and water and sky are indistinguishable… Ambient luminescence produces shadowless illumination. It minimizes form and bulk. It minimizes the importance of all things and people. It suggests the freedom of space and can suggest infinity. It is usually reassuring. It quiets the nerves and is restful… It is any art gallery with strip-lighted walls, translucent ceiling, and white floor.

Luminous ceilings have evolved to now provide the other two elements of lighting, described by Kelly as:

Focal glow is the campfire of all time… It is the pool of light at your favorite reading chair. It is the shaft of sunshine that warms the end of the valley… Focal glow draws attention, pulls together diverse parts, sells merchandise, separates the important from the unimportant, helps people see …

Play of brilliants is Times Square at night. It is the 18th-century ballroom of crystal chandeliers and many candle flames… Play of brilliants excites the optic nerves, and in turn stimulates the body and spirit, quickens the appetite, awakens curiosity, sharpens the wit. It is distracting or entertaining.

‘Focal glow’ can be achieved by variations in the intensity of light color from the transluminous ceiling. ‘Play of brilliants’ is the sparkle created when light shines through panel perforations or the facets of a clear panel.

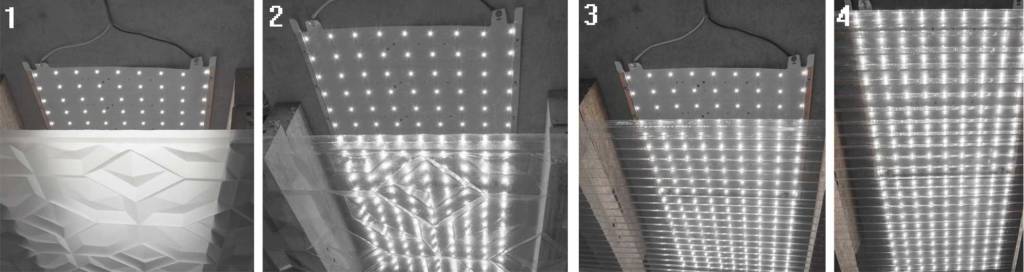

[15]

[15]Photos courtesy Fraunhofer Institute IOP

Kelly opines, “Visual beauty is the interplay of all three kinds of light.” To see how his thesis might apply to transluminous ceilings, one may consider a hotel that uses thermoformed ceilings throughout the facility, but changes lighting schemes to differentiate spaces and set the scene for various events. For example:

1. A transluminous soffit fills the porte cochère after dark with an inviting pool of light. By day, a skylight above the panels prevents the entry from feeling like a dark tunnel.

2. Stepping into the lobby, opaque ceiling panels are illuminated by pendant lanterns made by assembling transluminous panels into cubes.

3. To one side of the lobby, the registration desk is identified by a traditional luminous ceiling with bright, uniform, and diffuse lighting.

4. On the other side of the lobby, frosted panels are animated by changing displays of colored LEDs, projected images, and an above-ceiling mirror ball.

5. The ballroom is ready for any event; it has luminous ceiling panels, down lights, and indirect lighting from chandeliers and cove lighting. Strategically placed clear panels allow spotlights to be installed above the ceiling. The several types of lighting can be used individually or to create hybrid lighting schemes.

6. Hybrid systems are also used in the dining room to provide appropriate lighting for breakfast, lunch, dinner, and after-hours seatings.

7. The glare from sunlight streaming through skylights above prefunction areas is cut with frosted ceiling clouds that are artificially illuminated at night.

8. Meeting rooms on the south side of the building use luminous panels as light shelves.

9. Public toilet rooms have opaque panels in the center of the room framed by wall-washing luminous panels over both lavatories and toilet fixtures.

10. Merchandise in the gift store sparkles due to LED strip lights and spotlights located above clear ceiling panels.

11. Luminous ceilings in corridors ensure walls are evenly illuminated to make the hall feel more spacious and enhance the guest’s sense of security. Clear transluminous panels outside guest room doors provide additional light to aid in identity and assist guests fumbling with keys and luggage. The building management system that turns on a room’s air-conditioner when the guest registers also turns on a colored light to help guests find their rooms; the light turns off after the door is unlocked.

12. Guest rooms have a stylish transluminous wall that has been preprogrammed so guests can match the lighting color to the circadian rhythms of their hometowns to minimize jet lag. An app transforms the room into a party zone by manipulating lighting according to tunes on the guest’s mobile device.

13. The ceiling in the guest toilet room will not be damaged by humidity or aberrant sprays from showers.

14. The same water-resistant character allows panels to be used in locker rooms, laundries, and other back-of-house areas, as well as over pools and spas. The vinyl panels are nonporous, cleanable, and comply with Food and Drug Administration (FDA) and U.S. Department of Agriculture (USDA) requirements for kitchens.

You may be thinking, “Wouldn’t it be boring to use the same ceiling all over the building?” Many people feel the same way about ubiquitous mineral fiber ceiling panels. However, transluminous thermoformed ceilings facilitate endless variations in panel style, light transmission levels, and illuminance.

[16]

[16]Photo courtesy FamousMods.com

A future brightly seen

In several iterations of Star Trek, the bridges on Enterprise and Discovery have luminous ceilings—and why not? The crews of the spaceships require high-quality illumination, and so do the television and movie directors of photography. The distinction between ceiling and illuminant blurs; light appears to be coming from the ceiling and neither transmitted through or reflected from the surface. Science fiction can portend reality, and Gene Roddenberry and his disciples may be more prescient than we realize.

In extrapolating from contemporary trends, one finds interior daylighting is now available with tensioned fabric structures, building enclosures that are made of ethylene tetrafluoroethylene (EFTE) foils, and electrochromic (EC) and other types of glass, along with other wonders of modern material science. This is acclimating the public to the benefits of uniform overhead light.

LEDs have usurped the supremacy of incandescent, fluorescent, and other 20th-century lamps. Their reign is being challenged, in turn, by OLED (organic light-emitting diodes) and quantum-dot technologies even better-suited for use as thin light sources for luminous ceilings. Is viable bioluminescent lighting far behind? Will semiconductor technology advance to the level that light-emitting surfaces are simply painted onto structures?

Major lamp manufacturers have introduced their own take on luminous ceilings. Apple, an arbiter of contemporary taste, has patented a luminous ceiling system and is installing swaths of luminous ceilings as it remodels its stores. The technologies that make ever more thin and svelte cell phones and flat screens is leading to light-emitting surfaces flexible enough to apply like wallpaper.

Faced with the growing danger of antibiotic-resistant pathogens, designers of healthcare and cleanroom environments are turning to more hygienic ceiling systems that are washable and reduce the presence of light fixtures, sprinklers, and other utilities within controlled environments. (The article, “Lighting as an Integral Part of Architecture[17],” appeared in the Autumn 1952 issue of College Art Journal [vol. 12, no. 1]. )

Luminous surfaces are also finding their way onto walls, floors, and furniture. The light boxes employed to transilluminate retail signage are increasingly thinner. Lighting controls are becoming part of the Internet of Things (IoT) to enhance the customer or tenant experience and reduce power consumption.

While the luminous ceiling techniques developed in the 20th century still have relevance, designers are no longer limited by their aesthetic. New panel styles and installation methods are evolving to satisfy changing tastes and needs. Processes for manufacturing vinyl and other light-transmitting materials have become cleaner, and recycling programs are in place. Manufacturing of custom designs will continually be simplified as 3D printing techniques improve. It should not be surprising, therefore, that luminous ceilings are boldly going where no ceiling has gone before.

| DAYLIGHTING CONSIDERATIONS |

| Allowing daylight to enter a building can reduce the energy demand of electric lamps and is encouraged by energy conservation building codes. Programs like the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED) and the WELL Building Standard also encourage daylighting for its positive psychological impact on building occupants.

Luminous ceilings can play a role in two daylighting scenarios: top- and side-lighting. Top lighting Skylights typically have less thermal insulation value than the roof around them. Installing a luminous ceiling within the light well beneath the skylight creates a buffer that retards heat loss. Some skylights are meant to be seen and even to provide views of the sky. Yet, in other locations, designers may want to minimize visibility of skylights while optimizing daylighting value. In the latter case, luminous ceilings conceal skylight while still harvesting daylight. Side lighting |

Ed Davis is president of Ceilume, a manufacturer of thermoformed ceiling panels, and has been responsible for product testing and obtaining product evaluations and approvals. He can be reached at ed@ceilume.com[18].

David Condello, CSI, has more than 20 years of experience in construction and is the architectural services manager for Ceilume. He can be reached at david@ceilume.com[19].

Michael Chusid, RA, FCSI, CCS, is an architect, a Fellow of CSI, and a Certified Construction Specifier. He is a frequent contributor to The Construction Specifier, and a consultant to building product manufacturers. He can be reached at www.chusid.com[20].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/TranslucentPanelSoftened-Edit-e1501253330681.jpg

- www.google.com/patents/US2710335: http://www.google.com/patents/US2710335

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/fig1-1.jpg

- luminous ceiling: http://bit.ly/Wakefield-LuminousCeilings

- 2014 article: http://www.constructionspecifier.com/thermoformed-ceiling-panels-and-tiles

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/clear-panels-direct-light.jpg

- Standard, V1, Q2 2017 Version; Feature 55: http://standard.wellcertified.com/light

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/DSC_0099-Edit-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/IMG_3612.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/four-way-comparison-label-2.jpg

- drop-out ceiling: http://bit.ly/WhitePaper-DropOutCeiling

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/IMG_1728-Edit-Edit-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/edit1-1.jpg

- Fire and Materials: http://bit.ly/2u0oFfb

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Fraunhofer-IAO-sky-lightskybrightintheoffice2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/IMG_9166-Edit-Edit.jpg

- Lighting as an Integral Part of Architecture: http://bit.ly/2s6kkVZ

- ed@ceilume.com: mailto:ed@ceilume.com

- david@ceilume.com: mailto:david@ceilume.com

- www.chusid.com: http://www.chusid.com

Source URL: https://www.constructionspecifier.com/ceilings-become-transluminous/