Cellular glass insulation

Solutions beyond the roof

The properties that make cellular glass an insulating material for commercial roofing applications also address performance issues confronting architects in other parts of the enclosure, including walls and below-grade areas. For example, the compressive strength of cellular glass coupled with its R-value allows the material to serve as a connector between the roof layer and the continuous insulation (ci) on the wall, thus making the insulation jacket continuous (Figure 2). The cellular glass provides not only the strength of a concrete block for weight-bearing purposes, but also the R-value required to meet insulating needs, which is impossible with concrete. The insertion of cellular glass interrupts the thermal bridge efficiently.

Cellular glass’s strength and thermal properties help it deliver both loadbearing and thermal-bridging mitigation in below-slab applications. These below-grade performance requirements cannot be achieved with foam plastics.

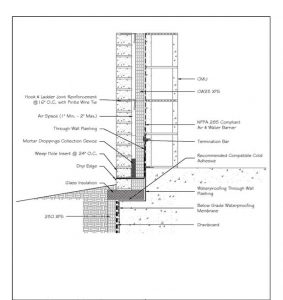

The performance benefits cellular glass brings to the walls of the enclosure also apply to below-grade areas. For example, brick veneer placed on a bearing shelf in order to transfer dead load into the foundation has been accepted as a necessary thermal bridge to accommodate load resolution into the foundation. There is a ci path and a load-resolution path in the enclosure. The two paths cannot cross without a ‘structural insulation’. The load path must always take priority. However, cellular glass offers the necessary strength to provide a structural solution permitting the ci path to cross over the load-resolution path. Figure 3 (page 40) shows how cellular glass insulation crosses the load resolution path, connecting the ci to provide uninterrupted insulation, and avoiding a thermal bridge from the brick veneer into the foundation.

The evolution of energy codes in the United States over the past 30 to 40 years have largely helped to improve the energy efficiency of the building envelope. Today’s internal loads are more efficient, and insulation R-value levels in walls and roofs are better. Thus, previously overlooked areas of thermal inefficiency are now receiving new scrutiny—and the industry is embracing micro-efficiencies to be able to deliver continuous improvements in energy efficiency. Precision improvements are becoming more important in energy-saving endeavors and cellular glass used in the enclosure can help optimize these efforts.

The installation of the material on a jobsite should also be considered. At a time when demand for construction labor is high, cellular glass insulation does not require any special skill set. It may be installed using hot asphalt, cold-applied asphalt adhesives, or two-part polyurethane adhesives—all methods familiar to roofing contractors.

Cost-benefit analysis

As noted earlier, architects should perform a cost-benefit analysis to compare the potential costs of a failure against the higher cost of a building material. The performance benefits of cellular glass come with a cost premium compared to foam plastic insulation options. If an architect is specifying building materials purely based on material cost, cellular glass will not be an option. However, if an architect is looking for materials value addition—including the confidence, peace of mind, and potential savings that come with avoiding a roof leak in a mission critical building—cellular glass is suitable.

The functionality of cellular glass can replace other layers in the construction system such as vapor retarders, moisture barriers, and radon-control components. Cellular glass may also enhance longevity and deliver environmental attributes desired by building owners and occupants. Used under loadbearing slab applications, the rigidity of cellular glass might even make it possible to install a thinner or less heavily reinforced concrete slab.

From the commercial rooftop, throughout the enclosure’s walls, and in below-grade applications, cellular glass is providing architects with a proven option for insulating mission critical buildings.