A sustainable solution

Images courtesy International Institute for Sustainable Development

Continued global growth and the trend toward urbanization means building material solutions must be abundant, affordable, and easily adapted to meet future needs. Concrete is a sustainable solution striking a strong balance between the social, environmental, and economic aspects of the communities’ infrastructure needs (Figure 3).

Strength

Concrete offers good compressive strength for the cost and weight of materials, where other structural characteristics can be enhanced through reinforcing materials. While the compressive strength of conventional concrete is typically less than 50 MPa (7 ksi), high performance concrete mix designs used in high-rise construction can have compressive strengths of up to around 100 MPa (14 ksi), and ultra-high performance concrete (UHPC) can have compressive strengths of more than 180 MPa (26 ksi). By carrying loads more efficiently, the quantity of materials and overall costs for a structure can be reduced. Similarly, lower strength and lower density concrete made with lightweight aggregates produced from recycled materials can help reduce the dead load of buildings.

Versatility

Concrete is flexible, robust, and workable. Mix designs can be adapted to optimize performance and concrete can be placed in a variety of conditions by various methods while offering reliable and predictable performance. Due to its initial plastic state and workability, concrete is able to fill any shape or form to create elegant straight lines or complex geometries, offering a plenitude of architectural and structural options to both the designer and owner.

Raw materials

The materials used for concrete construction are locally sourced, and readily available and mined from the earth’s crust, resulting in low-impact resource extraction and transportation. Aggregate, which comprises the largest proportion of material in concrete, requires little processing and is naturally occurring and locally available. Also, mineral extraction is tightly regulated, and sites can be restored in order to deliver a biodiversity gain to the surrounding environment (Visit en.wikipedia.org/wiki/Crust_(geology) and www.quarrylifeaward.ca/what-quarry-life-award.).

Durability and resilience

Concrete is durable and able to provide a long service life in a variety of natural climates and environments, resisting weathering action, chemical attack, moisture, and abrasion while maintaining its engineering properties. Additionally, reinforced concrete offers resistance to natural disasters and a changing climate. Concrete is sometimes used in areas where it is exposed to substances that can cause deterioration. In such situations, high-durability mix designs that employ a low water-to-cement materials ratio and a high quantity of supplementary cementitious materials (SCMs) can be enhanced by application of protective coatings or membranes (Refer to the “Effects of Substances on Concrete and Guide to Protective Treatments” by Beatrix Kerkhoff.). However, consideration must be given to the Living Building Challenge’s Red List.

Energy efficiency and healthy living environment

Concrete offers advantages to energy performance such as reduced heating and cooling costs through its excellent thermal mass, with a high heat capacity for storage (around 1000 J/kgoK) and moderate thermal conductivity (around 0.5 to 3 W/moK). Additionally, concrete can result in mitigation of the urban heat-island effect, and increased lighting efficiency due to an albedo reflectance of around 0.35 and solar reflective index greater than the threshold value of 29 required for hardscape in most green building standards and rating systems. It also offers improvements in air quality due to negligible levels of volatile organic compounds (VOCs) and elimination of uncontrolled through-wall infiltration, which can be enhanced through the use of photocatalytic cements that remove and decompose contaminants from the air. Concrete also offers effective sound attenuation, with concrete masonry units (CMUs) offering sound transmission classes (STCs) from 40 to over 60 depending on thickness, density, and design.

Adaptability

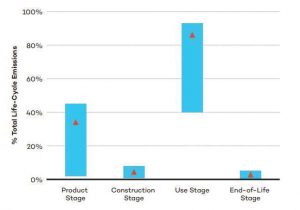

The use of concrete not only reduces maintenance and operational costs of buildings over their service life, with up to 10 percent lower annual operating GWP than alternative designs, but also provides the option to repurpose, reuse, or recycle structures and the materials at the end-of-life, decommissioning stage.

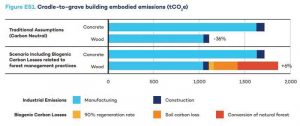

Absorption of CO2

Just like trees, concrete naturally absorbs CO2 from the atmosphere. Science shows concrete absorbs the equivalent of up to 25 percent of the emissions generated in creating it over its lifespan.

Low-carbon innovation

Innovations in the cement sector ranging from lower carbon cements and low-carbon fuels and materials from the waste stream to investment in carbon capture utilization and storage technologies are putting concrete on a path toward carbon neutrality. These effects could even transform the material from a significant emitter of carbon into a carbon sink.