Choosing appropriate UL designs

by Jennifer Wilson | September 4, 2015 9:29 am

[1]

[1]by Eric Montplaisir, PE

Many UL designs have load restrictions—a matter of great importance and potential liability for engineers of record (EORs), who, in accordance with several building codes and the UL Fire-Resistance Rating Directory, are responsible for identifying and approving the use of such designs on a project. Understanding which designs are restricted, and calculating the load restrictions, can be a complex process.

Background

The International Building Code (IBC) requires the fire-resistance rating of building elements, components, or assemblies be determined by the test procedures set forth in ASTM E 119, Standard Test Methods for Fire Tests of Building Construction and Materials or UL 263, Standard for Fire Tests of Building Construction and Materials. Under these standards, the members being tested must be loaded as near as practicable to the maximum allowed under nationally recognized structural design criteria.

The American Institute of Steel Construction (AISC) provides two methods for calculating the load: Limit States Design method (LSD) and Working Stress Design method (WSD). Until 2006, these methods yielded different results under identical conditions; however, AISC changed the calculation process for WSD (i.e. allowable stress design method) in the 2005 American Institute of Steel Construction (AISC) Specification for Structural Steel Buildings. This change resulted in the two methods generally ending in the same design loads. This change was first adopted in the 2006 IBC.

However, several UL designs used the pre-2006 WSD Method—where structural members were tested with lower loads than those called for by the LSD or post-2006 WSD methods. Thus, according to UL[2], assemblies tested using the latter methods would have a shorter fire-endurance period. To address this discrepancy, load restrictions are imposed on UL designs evaluated under the pre-2006 WSD method, as stated in the disclosure at the front of the design:

This design was evaluated using a load design method other than the Limit States Design Method (e.g., Working Stress Design Method). For jurisdictions employing the Limit States Design Method, such as Canada, a load restriction factor shall be used – See Guide BXUV

The above disclosure states “for jurisdiction employing the Limit States Design Method,” when in fact, a more appropriate statement is “for projects employing the Limit States Design Method.” The design method is, in fact, the choice of the project team. While the US does not mandate the use of the LSD Method as Canada does—it is widely used throughout the US design community. Even if the post-2006 WSD Method is used, the result is the same.

[3]

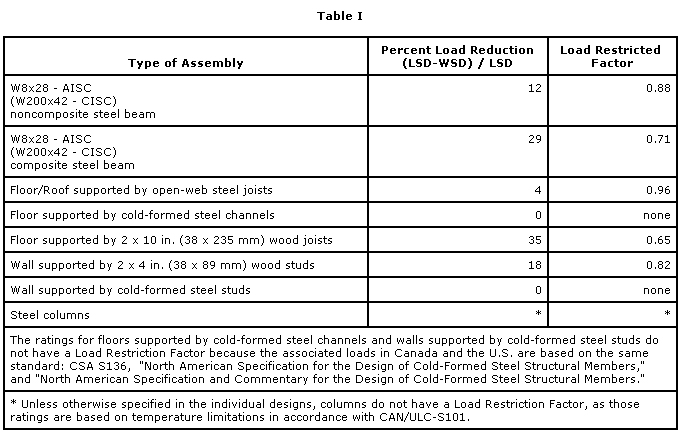

[3]Evaluation and selection of design

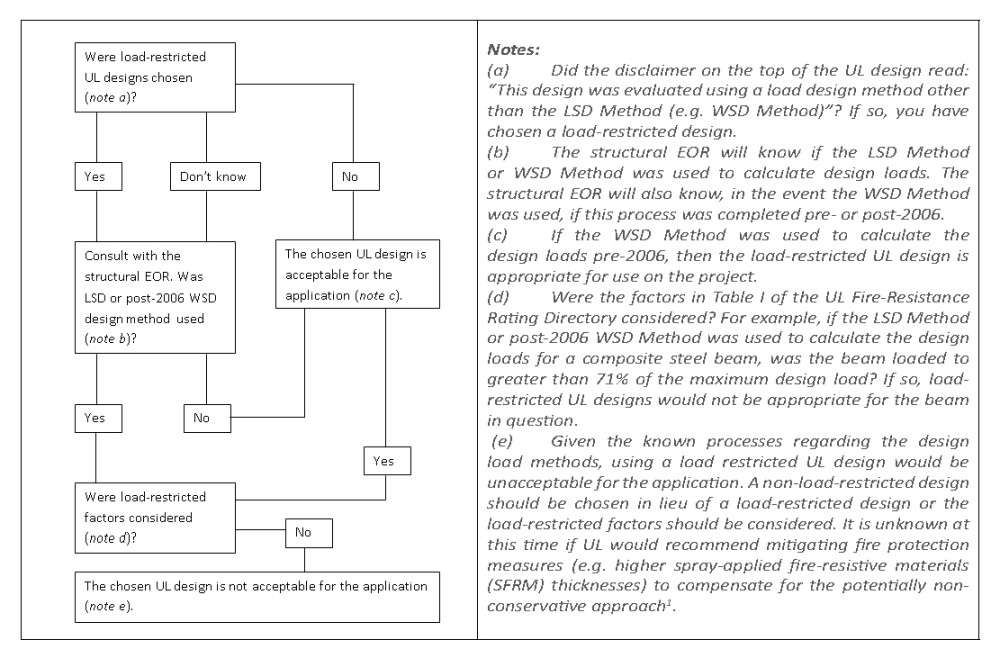

If a project uses the LSD or the post-2006 WSD method to calculate design loads—either of which would yield the same result—the UL design with the above disclosure cannot be used except when the guidance at the front of the UL Fire-Resistance Rating Directory is considered. When the load restriction factors (see right) are applied to maximum design loads calculated under these design methods, a new load-restricted maximum design load is established in which load-restricted UL designs can be used. If the actual design load exceeds the new load-restricted maximum design load, a load-restricted UL design is not appropriate for the project and cannot be used.

[4]

[4]The Directory further notes the EOR [5]should be consulted whenever fire-resistive assemblies with load restrictions are selected for a project by the architect or contractor, because the latter two may lack adequate and accurate information for determining whether such a design can, in fact, be used. Thus, UL has assigned the responsibility for verifying that appropriate UL designs have been chosen to the EOR. That process calls for an open dialogue between architects and structural, engineers and should include the general guidelines found in Table 2 (Above).

Conclusion

The intent of this article is to point out the complexities involved in choosing an acceptable UL design for each specific application and to help the Engineer of Record (sometimes an architect or a structural engineer) make the right choice. The flowchart above is a helpful tool in evaluating the viability of the chosen solution. If questions remain following this analysis, it is advisable to consult a qualified industry professional, such as a structural engineer, a fire/life safety engineer, or a code consultant.

[6] Eric Montplaisir is a code consultant in the Boston office of AKF Group, a full service consulting engineering firm serving public and private sector clients across the United States and around the world. Eric has an impressive background in fire protection engineering and code consulting—including fire modeling services, atrium smoke modeling analysis, structural steel analysis, and code conformance reviews. He holds Master of Science in Fire Protection Engineering, and Bachelor of Science in Mechanical Engineering degrees, and is a Licensed Professional Engineer, Fire Protection, in Massachusetts. He is a Professional Member of the Society of Fire Protection Engineers (SFPE), and the National Fire Protection Association (NFPA). He can be reached at emontplaisir@akfgroup.com[7]

[6] Eric Montplaisir is a code consultant in the Boston office of AKF Group, a full service consulting engineering firm serving public and private sector clients across the United States and around the world. Eric has an impressive background in fire protection engineering and code consulting—including fire modeling services, atrium smoke modeling analysis, structural steel analysis, and code conformance reviews. He holds Master of Science in Fire Protection Engineering, and Bachelor of Science in Mechanical Engineering degrees, and is a Licensed Professional Engineer, Fire Protection, in Massachusetts. He is a Professional Member of the Society of Fire Protection Engineers (SFPE), and the National Fire Protection Association (NFPA). He can be reached at emontplaisir@akfgroup.com[7]

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/05/bigstock-Architect-designing-on-draftin-82646537.jpg

- UL: http://canada.ul.com/wp-content/uploads/sites/11/2015/03/Information_Bulletin_2015-01ENG-CAN-ULC-S101-14.pdf

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/09/CE-July132015-Table-1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/09/CE-July-13-2015-Table-2.jpg

- EOR : http://lpcorp.com/media/2597/bxuvu349-fire-resistance-ratings-ansi_ul_263-english.pdf

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/09/070314-5.jpg

- emontplaisir@akfgroup.com: mailto:emontplaisir@akfgroup.com

Source URL: https://www.constructionspecifier.com/choosing-appropriate-ul-designs/