by John Koester

While some building science concepts can be difficult to grasp, there is nothing new or complex about the relationship between temperature and moisture management. The phrases ‘wet and cold’ or ‘warm and dry’ are ingrained in the minds of the public for good reason.

The law of physics dominating this phenomenon is thermal conductivity. Dense materials transmit temperature more efficiently than less dense ones because the molecules are closer together. Water is denser than air and transmits temperature 25 times more efficiently. When a person is wet, the ambient air temperature can be received more readily and the body loses temperature to the surrounding ambient air more easily if the latter is colder. A practical example can be found in the kitchen—moving one’s hand into a 200-C (400-F) oven, without touching any surfaces, is quite different from plunging a hand into boiling water.

Good thermal insulators—sprayed polyurethane foam (SPF) and rigid boardstock, for example—have a lot of air molecules in proportion to other dense molecules; further, the former is effectively positioned between the latter to make this separation. A good example of this is the cardboard sleeve that slides around a paper cup of hot coffee, allowing someone to comfortably hold a steaming beverage.

The clear takeaway for the building industry is to have an impact on a temperature relationship of a building from inside to outside (or outside to inside), one must insulate the exterior building envelope—the walls, floors, and roof (Figure 1).

Another critical requirement is keeping the insulation material dry. Wet insulation is not an insulator, but rather a conductor. Different types of insulation materials absorb moisture at different rates. In many instances, an exterior building envelope with no insulation is preferable to one with wet insulation. Of course, the problems of wet insulation in a wall do not end with just poor insulation values. They also include mold, pest infiltration, and building material degradation.

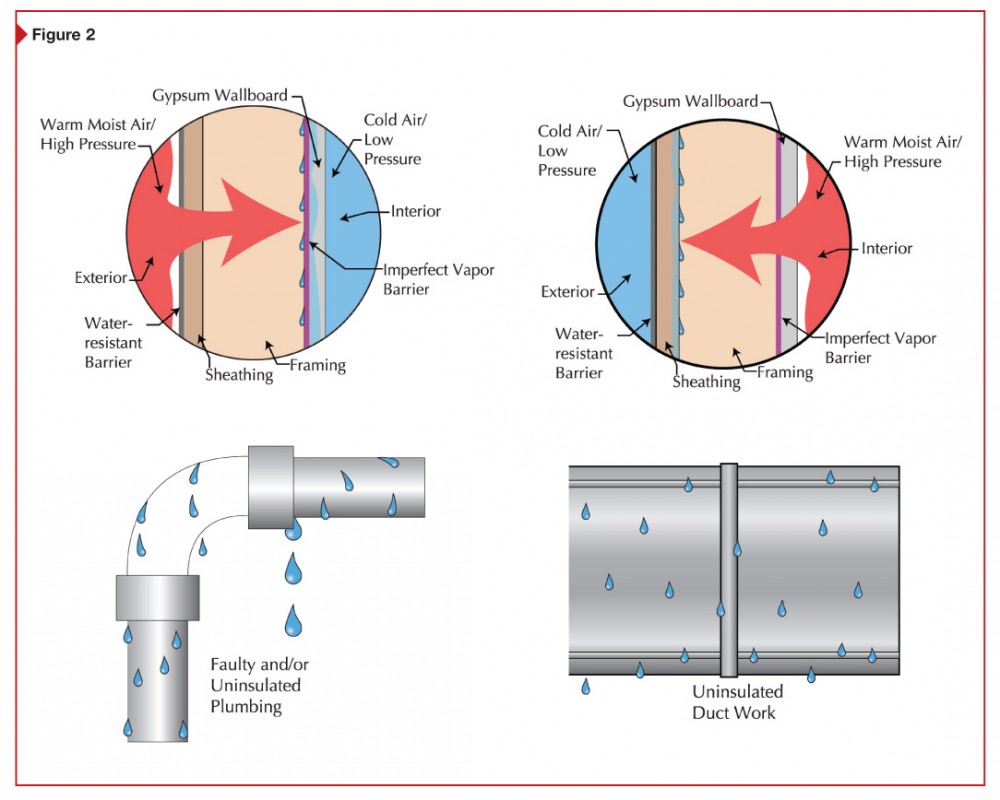

As shown in Figure 2, there are many causes of wet insulation in the exterior building envelope. Examples include:

- uncovered insulation stored in an exposed location on a jobsite can be installed in a damp/wet state;

- liquid water can egress into the exterior building envelope during and after the construction phase;

- moisture (in the form of water vapor) can enter the building envelope from the exterior and interior;

- liquid water can leak from faulty plumbing; and

- poorly insulated plumbing or HVAC ductwork can condense and drip water.

Moisture problems with EIFS are often in areas where the system abuts other materials such as wood trim, at the top wall, at roof flashing, around wall openings, and where other items penetrate the cladding’s surface. EIFS can also develop penetrations over time—foundations move, walls crack, storms can blow debris into façades, etc. There can often be installation issues. Even though manufacturers of EIFS products have recommended best practices and procedures, onsite labor does not always follow them; components like flashing can be improperly installed or omitted.

As the National Institute of Building Sciences’ (NIBS’) Whole Building Design Guide states:

Problems observed with in-service EIFS installations are primarily related to moisture intrusion. EIFS provides protection against moisture infiltration at the base coat; however, moisture migration through openings for windows, flashings and other items, or holes and cracks in the EIFS itself, have allowed leakage to occur on EIFS clad buildings. With barrier EIFS installations, or where weather barriers and flashing are improperly installed in conjunction with wall drainage EIFS installations, moisture has entered the wall system at these locations and caused damage to the wall sheathing and framing. The extent of these occurrences on wood frame structures has led to class action lawsuits.1

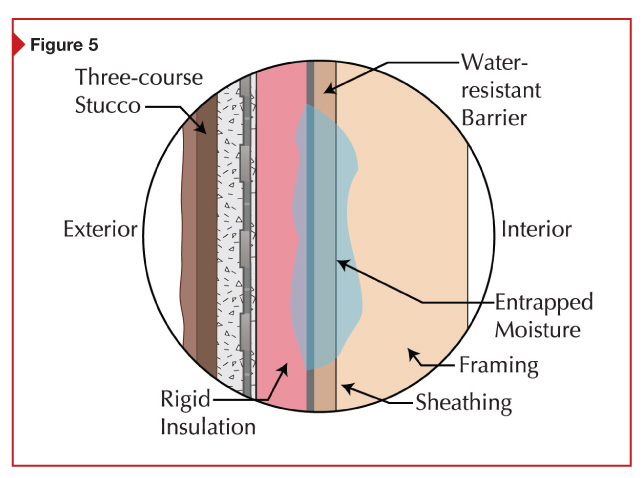

EIFS and entrapped moisture

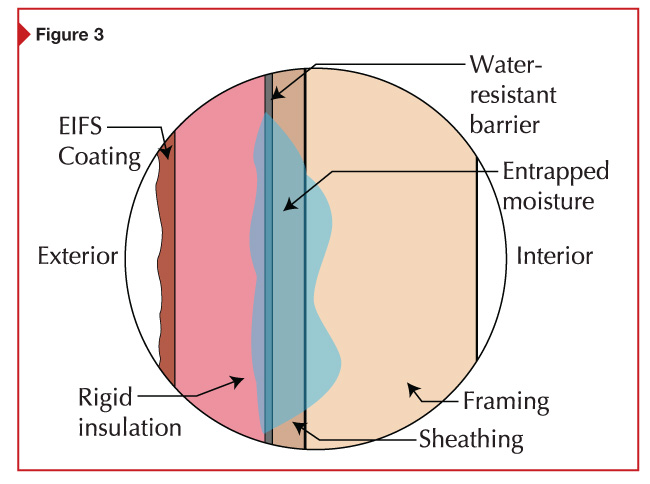

There are additional scenarios that have caused a great deal of problems. For example, issues occur when board stock rigid insulation is layered against other rigid insulation or exterior sheathing, or when decking traps moisture between the layers of material. This phenomenon first happened on a wide scale in early exterior insulation and finish systems (EIFS). Moisture entered these systems and became entrapped behind the rigid insulation and in front of the wall sheathing on the backup wall, deteriorating the water-resistant barrier (WRB), sheathing, and structural studs (Figure 3).

Moisture entering these early EIFS assemblies (through any of the methods previously mentioned became held for an extended period in the pockets/voids in the exterior building envelope created by the variations between the rigid insulation surface and the wall sheathing surface. This negative scenario was amplified by the composition of the two layers of materials involved.

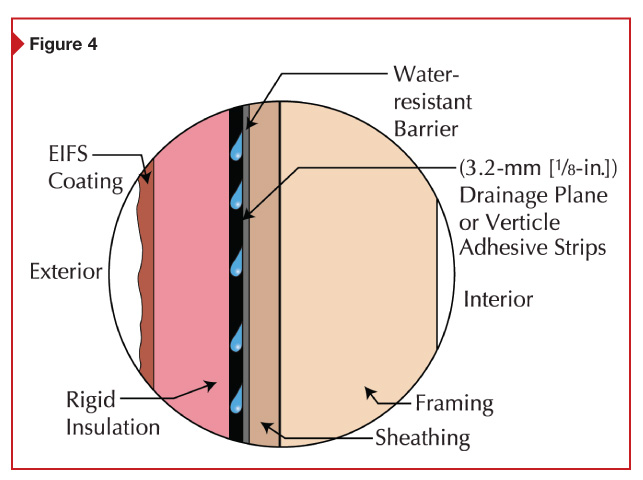

The EIFS industry started addressing this problem by incorporating a 3.175-mm (1/8-in.) drainage plane between the back side of the board stock rigid insulation and the exterior face of the sheathing or the WRB installed over the sheathing. Created through vertical adhesive patterns and/or strips of manufactured drainage material (Figure 4), this void became the accepted solution because it caused the least decrease in R-value while maintaining effective drainage characteristics. It also allowed accumulating moisture to effectively drain down and out the wall.

Additionally, this size was chosen because anything smaller could have allowed capillary action. When a wet layer is in close proximity to a dry one (i.e. less than 3.2 mm [1/8 in.] of separation), moisture moves between them. As the Whole Building Design Guide states:

Once wetted, capillary transfer within, or between, layers of an exterior wall assembly can also occur, and can be further exacerbated by moisture loads inherent to an exterior wall product or material shortly after initial installation.2

These voids are not widely promoted features of EIFS because the cladding systems qualify, under the International Building Code (IBC), as “barrier systems.” In other words, they are not supposed to allow moisture to penetrate into the building envelope and accumulate. The following information comes from an International Code Council Evaluation Service (ICC-ES) report of a major EIFS manufacturer’s product:

Compliance with the following codes:

- 2012 and 2009 IBC; and

- 2012 and 2009 International Residential Code (IRC).

EIFS: IBC Chap. 14, IRC Chap. R7

Weather resistance: IBC Chap. 14, IRC Chap. R7

Weather protection: complies with IBC Section 1403.2 and IRC Section R703.1

Granted, in a perfect world, EIFS would indeed work as a barrier system. However, walls do leak because of contractor error or issues with the installation of other products used in conjunction with the system. Therefore, since evidence showed moisture penetrated these systems, the EIFS industry’s decision to add a drainage plane to overcome the entrapped moisture problem is important. As this information was at one time proprietary and not widely disseminated, the requirement for and effectiveness of a drainage plane as a remedy for entrapped moisture is not fully appreciated by the construction industry.

It is important to note this article is not intending to single out and disparage the EIFS industry. In fact, it should be seen as just the opposite—EIFS manufacturers have made significant strides in successfully remedying the entrapped moisture problem by adding a drainage plane. Further, it is critical to remember the entrapped moisture problem is not exclusive to just one type of building envelope system.

The problem with two barriers

Enter the new energy code requirements: the 2009 International Energy Conservation Code (IECC) for residential buildings and American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 90.1-2007, Energy Standard for Buildings Except Low-rise Residential Buildings, for commercial buildings. (The 2012 IECC, requiring even stricter standards, may soon be adopted in some locations.) To comply, the building industry is specifying rigid board stock insulation to be applied outside the wall sheathing.

In so doing, the industry may be unwittingly creating a system remarkably similar to the early EIFS, but without the benefit of the drainage plane. There are numerous ongoing discussions in the construction industry related to this application (Figure 5):

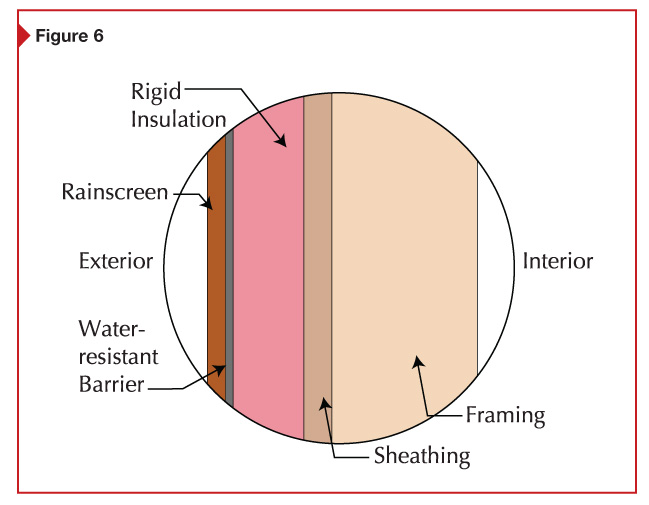

- Should the WRB be installed over the rigid insulation (Figure 6)?

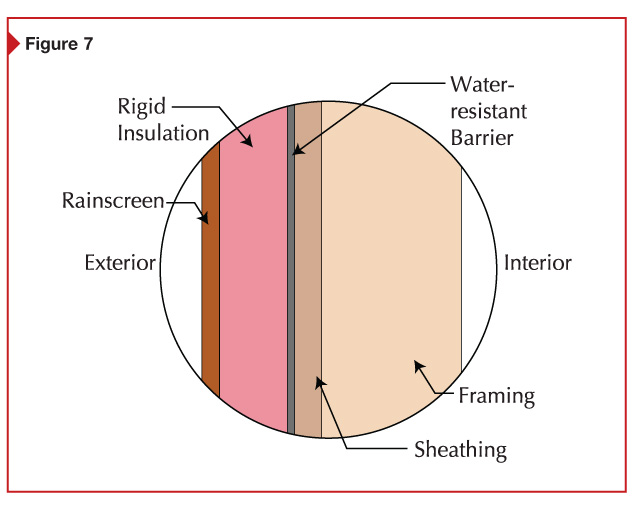

- Should the exterior sheathing and rigid insulation (with taped seams) be installed atop the WRB (Figure 7)?

- Does rigid insulation with taped seams qualify as a WRB?

- Is rigid insulation with taped seams a vapor retarder?

This author sees most types of board stock rigid insulation with taped seams as ‘vapor retarders.’ If this is the case, then the consequences of two or more vapor retarders as components of the same exterior building envelope system are very real.

There is nothing wrong with two or more vapor retarders in one exterior building envelope—provided no moisture is trapped between them. Similarly, there is nothing wrong with moisture being trapped between two or more vapor retarders in an exterior building envelope—provided the amount is small, and there are no other construction details involved that could rot or harbor microorganism growth. Of course, both of these scenarios provide potential problems given the criteria.

Conclusion

When it comes to claddings and entrapped moisture management, denial and ignorance are rife. “I do not have to worry about moisture being trapped in the exterior building envelope because it cannot get there” is the former, while “I didn’t know that material was a vapor retarder” is the latter.

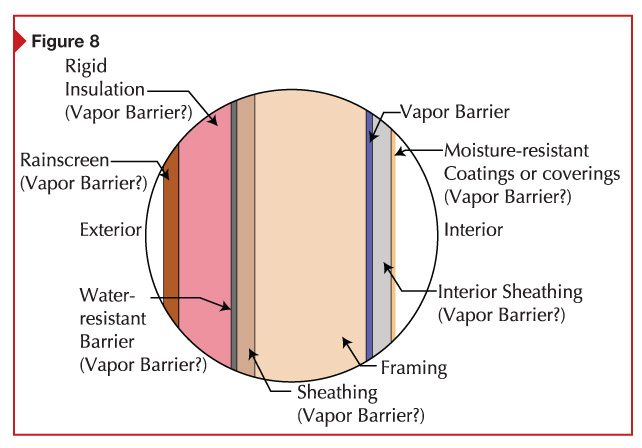

While a sense of denial is inexcusable for design/construction professionals, the ignorance can be more understandable. There are many choices for exterior building components that may qualify as vapor retarders under various conditions and configurations:

- rigid insulation (and other types of insulation);

- certain veneers/rainscreens;

- both interior and exterior sheathings;

- interior vinyl wallcoverings;

- some paints and coatings;3 and

- polyethylene sheets and other products specifically billed as ‘vapor retarders.’

Knowing how the wide range of components in the exterior building envelope interacts with each other under various conditions is not easy. Nevertheless, it is the responsibility of the specifying professional to research and determine what components and configurations will function properly. The term ‘holistic building’ is not just a catch phrase—it is a requirement that allows an exterior building envelope to function effectively in the long term (Figure 8).

Notes

1 Visit www.wbdg.org/design/env_wall.php. (back to top)

2 See note 1. (back to top)

3 Vapor retarder paints typically have a perm rating of 0.8 to 0.45, but the actual perm in the field depends on the number of coats and the degree of coverage. For more information, read the Journal of Light Construction article, posted at www.jlconline.com/paints/q-a–vapor-retarder-paints.aspx. (back to top)

John Koester is the founder and CEO of Masonry Technology Inc. With construction experience dating back almost 40 years, he has been a card-carrying mason and cement-finisher, and for many years operated his own masonry construction business in the Minneapolis-St. Paul area. Koester has extensive background in waterproofing systems in the areas of forensics, design, and installation oversight—both in restoration and complete re-roofing projects. He can be contacted via e-mail at john@mtidry.com.

It indeed is going to be a wonderful article,just read thru two paragraphs & feel placing comments.Your explanation is so simple and logical.Ever thought of teaching science to young students…..?