by Catherine Houska, CSI

With appropriate specification, stainless steel can last the life of a building. However, as with any other material, unsightly surface deposits can accumulate after many years of service. Accidents, vandalism, use of inappropriate cleaning procedures, and installation issues can make surfaces unsightly, cause damage, or even lead to rapid surface corrosion. Surface restoration is often possible with the right remediation approach.

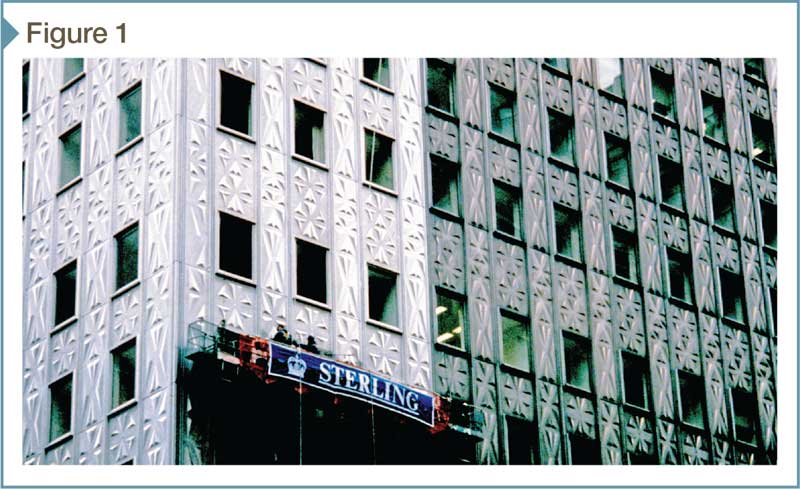

Since its invention over a century ago, stainless steel’s durable beauty has been repeatedly demonstrated. In the mid-1990s, more than 30 years of dirt, hydrocarbons, and other deposits had blackened the iconic upper floors of New York’s Chrysler (left) and Empire State buildings, but simple cleaning with products commonly found in household kitchens returned them to their original appearance (Figure 1).

The inherent corrosion resistance of stainless steel often makes it possible to restore surfaces after years of neglect when other materials may have suffered too much deterioration to make that feasible. This assumes an appropriately corrosion-resistant stainless steel and durable finish have been selected for the project, which have been the subject of this author’s previous articles. (Previous articles by this author for The Construction Specifier include “Proving its Long-term Mettle” [August 2016], “Avoiding De-icing Salt Corrosion” [January 2015], “Designing on the Waterfront” [November 2007], “Stainless Steel for Severe Coastal Environments” [September 2011], “Architectural Metal Corrosion: The De-icing Salt Threat” [December 2006], “Preventing Corrosion in Soil” [April 2006], and [co-authored with James Fritz], “Swimmingly Stainless Pool Design” [December 2005]. Visit www.constructionspecifier.com. See also this author’s articles for the International Molybdenum Association (IMOA) e-newsletter, Stainless Solutions, along with Architectural Metal magazine.)

General guidance

Environmental factors influencing the frequency of the routine cleaning required to retain a pristine appearance include:

- the owner’s aesthetic standards;

- surface finish roughness;

- airborne particulate concentrations;

- pedestrian traffic levels; and

- exposure to regular heavy rain.

Photo courtesy ATI Allegheny Ludlum

In exterior environments, sheltered areas (e.g. balconies or the lower floors on high-rises) can face more aggressive environments because rainwater cannot wash off corrosive surface deposits. A more corrosion-resistant stainless steel, smoother finish, and increased maintenance may be necessary to retain an attractive appearance.

One should always request the cleaning product’s Globally Harmonized System of Classification and Labelling of Chemicals (GHS) information or material safety and data sheet (MSDS), and avoid chemicals containing ‘chlor’ (i.e. chlorides), acids, particulate, and anything potentially corrosive or abrasive. When there are concerns, a stainless steel supplier, industry association, or consultant can review the product chemistry before it is used. (A cleaning company, blogger, or random website does not necessarily understand metal corrosion or specialized finishes.)

Proprietary detergent and water solutions, including those used for automotive or dishwashing, and ‘environmentally friendly’ cleaning products containing hydrogen peroxide, vinegar, or similar chemicals are also used. The detergent should contain both a surfacent and degreaser, not leave a coating on the surface, and preferably be chloride-free and pH-neutral (i.e. non-acidic). Many cleaning products and wipes contain chloride compounds, such as bleach (sodium hypochlorite). If such products are used, the chloride or bleach content should be less than three percent, and thorough rinsing to remove the chlorides is critical. Bleach concentrations of five percent or higher cause corrosion of commonly used stainless steels like Type 304/304L at room temperature, so it is critical not to let solutions dry and concentrate.