Wash water

Clean, potable water is used for rinsing surfaces after most cleaning procedures, but it is important to check the water’s chemistry. The U.S. Environmental Protection Agency (EPA) suggests no more than 250 ppm for chlorides and 500 ppm for total dissolved solids (TDS) for human consumption, but there are no hard maximums. In some areas, these levels are much higher, which could add to both corrosion and hard water staining problems.

Suitable water may need to be purchased or a reverse-osmosis (RO) system installed. It is important never to use natural untreated, industrial, or swimming pool water. When acidic cleaning products are used, the rinse water should have a maximum TDS content of 200 ppm or be de-ionized, distilled, or RO water—otherwise, hard water staining occurs (Figure 2). While it can be removed, opting for avoidance is far more cost-effective.

Applying cleaning products

Even durable finishes can be damaged with inappropriate cleaning methods—this is a particular concern for fragile mirror and colored finishes. Too often, ‘cleaning’ is attempted with abrasives only appropriate for refinishing. One should use a new or clean, soft, lint-free cloth or a clean sponge reserved for exclusive use on stainless steel. It is critical to avoid cleaning products used on other materials, such as carbon steel.

Products that can potentially change the finish appearance, or contaminate the surface with iron, include:

- coarse abrasives pads (e.g. sandpaper or non-metallic abrasives);

- metal scrapers, brushes, or wool pads;

- coarse abrasive powders; and

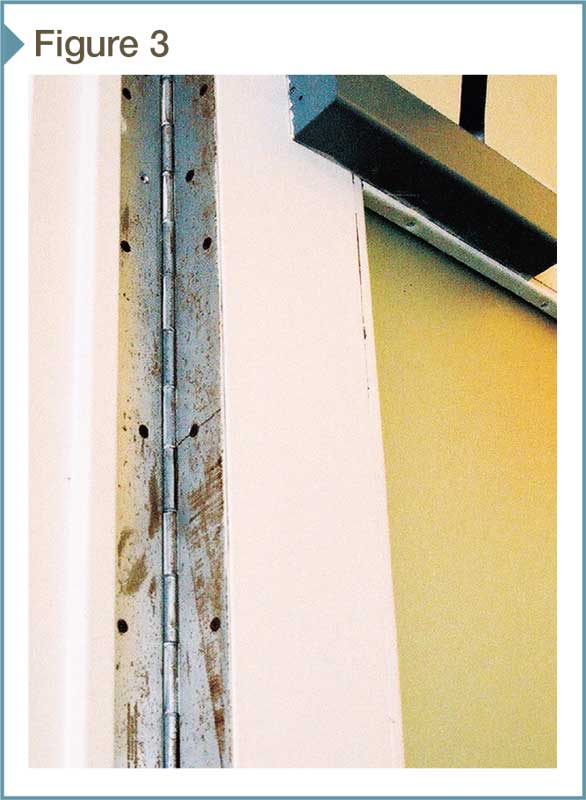

- abrasive blast media. (See Figure 3 for an example.)

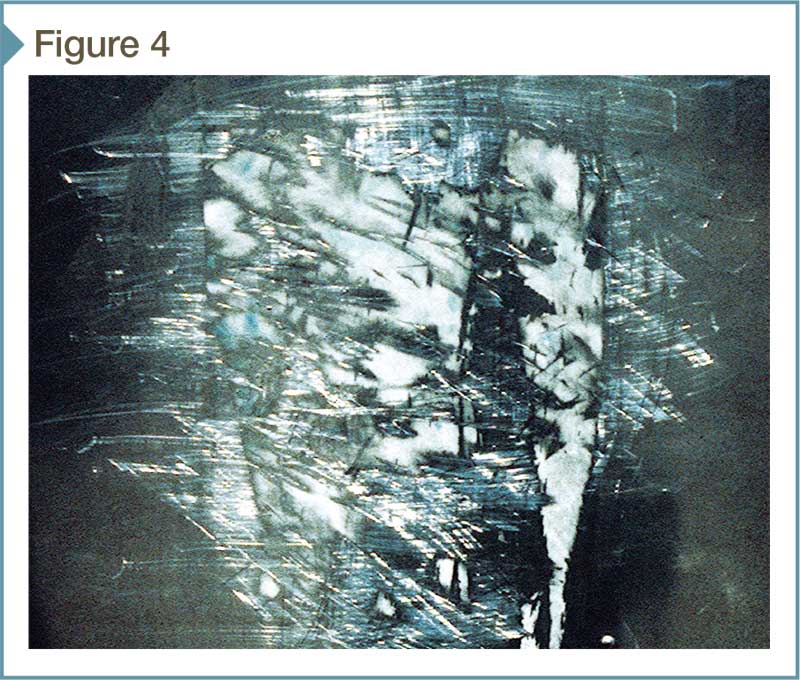

A soft nylon brush or plastic scraper can be used to help loosen adherent surface deposits, but should be tested first to ensure against surface damage. When cleaning directional finishes, one should always rub along the grain (Figure 4).

Light dirt, urine, and fingerprint removal

The choice of cleaning method for removing surface deposits, fingerprints, and other light discoloration depends on the application. Hand cleaning is common, but hot-water power-washing is appropriate for exterior applications where water infiltration is not a concern and a fast, low-cost cleaning option is desired.

Light fingerprints and dirt accumulations are also easily removed with common window cleaning products, such as ammonia and water or vinegar and water solutions. This makes it easy to clean adjoining stainless steel surfaces as windows are cleaned. These products are also suitable for other light cleaning requirements, but they will not remove heavier fingerprinting (Figure 5).

Mild detergent and degreaser solutions will increase cleaning effectiveness. If there are chlorides (coastal or de-icing salts) on the surface, cleaning effectiveness is increased by a proprietary additive specially formulated to improve removal.

Heavy fingerprints, grease, and oil

Heavy grease and oil deposits can be removed with vapor or steam de-greasing, high-pressure water jets, or alkaline or emulsion cleaners. Hot-water power-washing with a mild detergent or oil-free citric acid solution can also be effective. Some household oil-free citric acid cleaners and degreasers effectively remove many heavier fingerprint, oil, and lighter grease deposits.

Proprietary industrial strength degreasers, such as alkaline formulations with surfactant additions, are effective on heavier oil and grease deposits. Any new product should be tested on a small stainless steel surface before use to ensure it does not cause color change. Manufacturer instructions for application and surface rinsing must also be followed.